Linear array CCD based automatic welding seam tracking device and method

An automatic tracking device and line array technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large positioning error, lagging welding seam tracking technology control, and inability to quickly correct the deviation of the machine head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

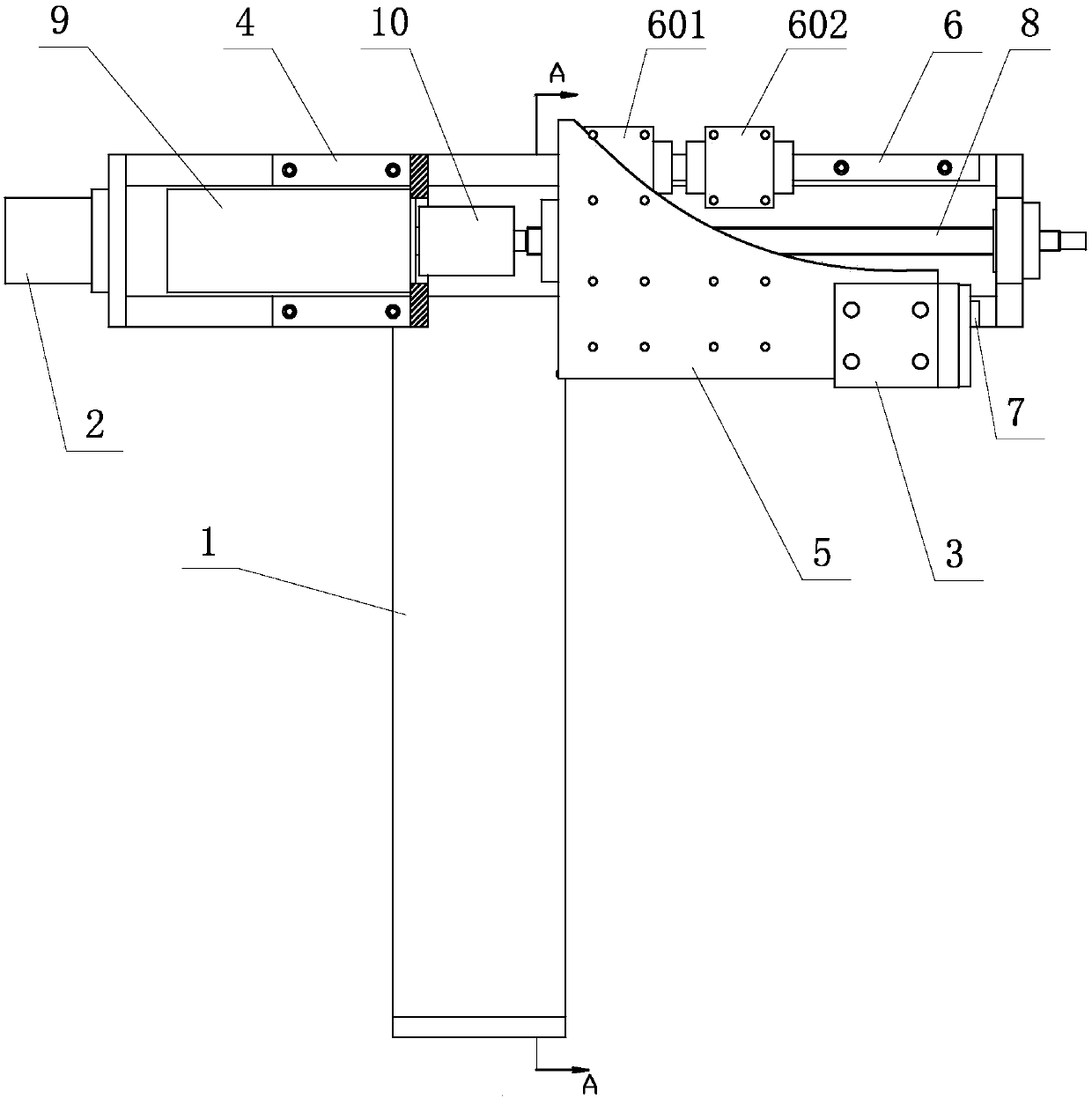

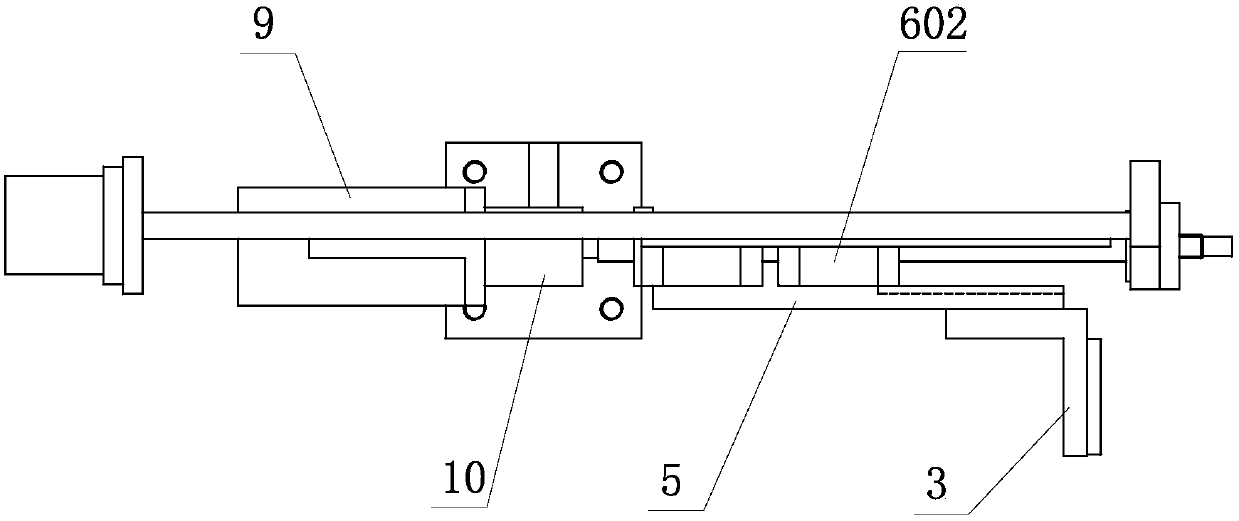

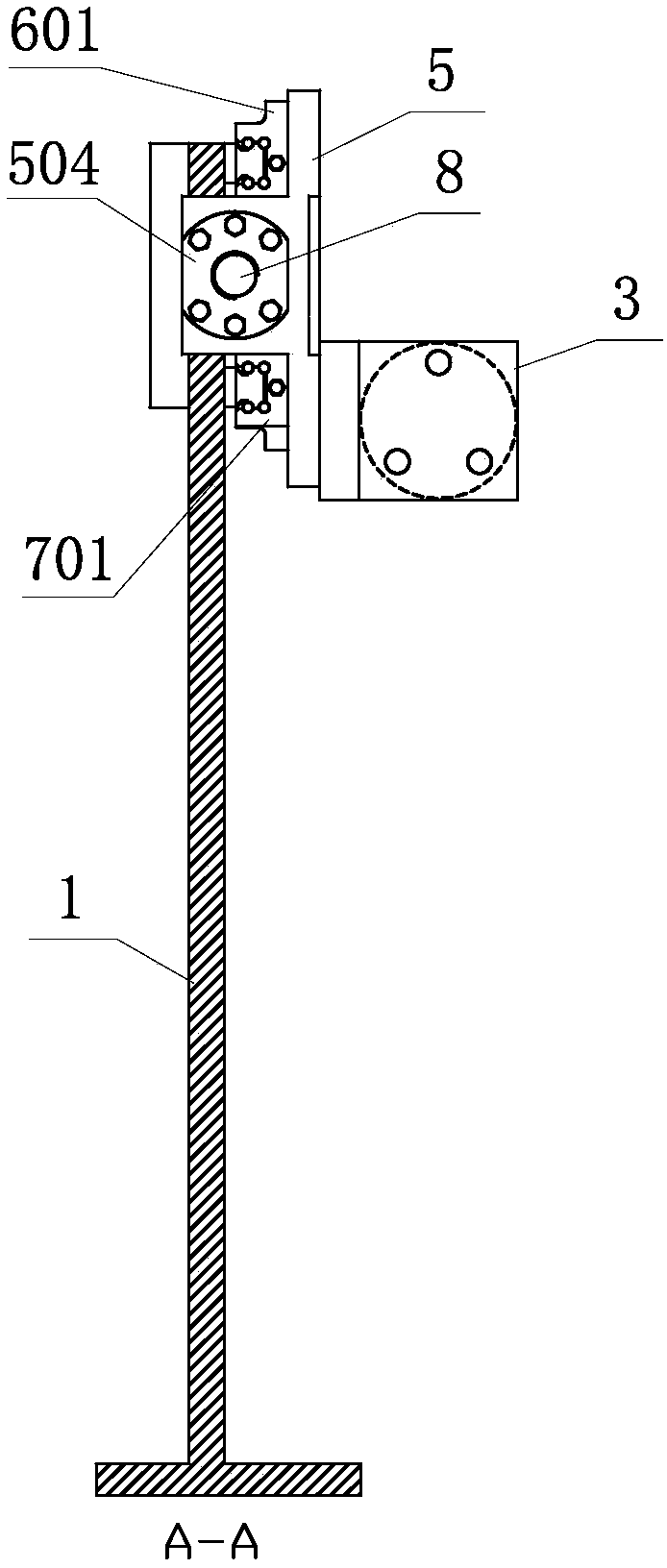

[0099] Such as Figure 1-3 As shown, the linkage mechanism includes frame 1, left head 2, machine head mounting frame 3, motor bracket 4, workbench 5, upper guide rail assembly 6, lower guide rail assembly 7, lead screw pair 8, servo motor 9, and coupling 10. The motor bracket 4 is connected to the frame 1, and the servo motor 9 is connected to the motor bracket 4; the upper rail assembly 6 and the lower rail assembly 7 are respectively connected to the frame 1; the left end of the screw pair 8 is connected to the servo motor through a coupling 10 The output shaft of 9 is connected, the right end of the screw pair 8 is connected with the right end of the frame 1 through the screw support base; The sliders on the top are respectively connected with the inner side of the workbench 5; the machine head mounting frame 3 is connected with the outer side of the workbench 5;

[0100] Such as Figure 4-7As shown, the frame 1 includes a support beam 101, a base 102, an upper installat...

Embodiment 2

[0138] In order to adjust the position of the machine head 50 in the vertical direction, a further improvement is made on the basis of the foregoing embodiment 1, so that the upper mounting beam 103, the lower mounting beam 104, the left head mounting plate 105 and the lead screw on the frame 1 are supported The rectangular frame formed by the seat mounting plate 106 is slidably connected with the support beam 101 . The specific structure is as Figure 27-29 As shown, it is realized by a vertical direction servo motor 11 , a vertical direction lead screw pair 12 , a left guide rail assembly 13 and a right guide rail assembly 14 .

[0139] The vertical direction servo motor 11 is fixedly connected with the support beam 101 through the vertical direction servo motor mount 11-1, the upper end of the vertical direction screw pair 12 is connected with the output shaft of the vertical direction servo motor 11, and the lower end of the vertical direction screw pair 12 passes through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap