Glass profiling device and glass profiling method

A glass and driving device technology, which is applied in glass forming, glass pressing, glass die-casting equipment, etc., to achieve the effects of high connection, precision assurance, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings.

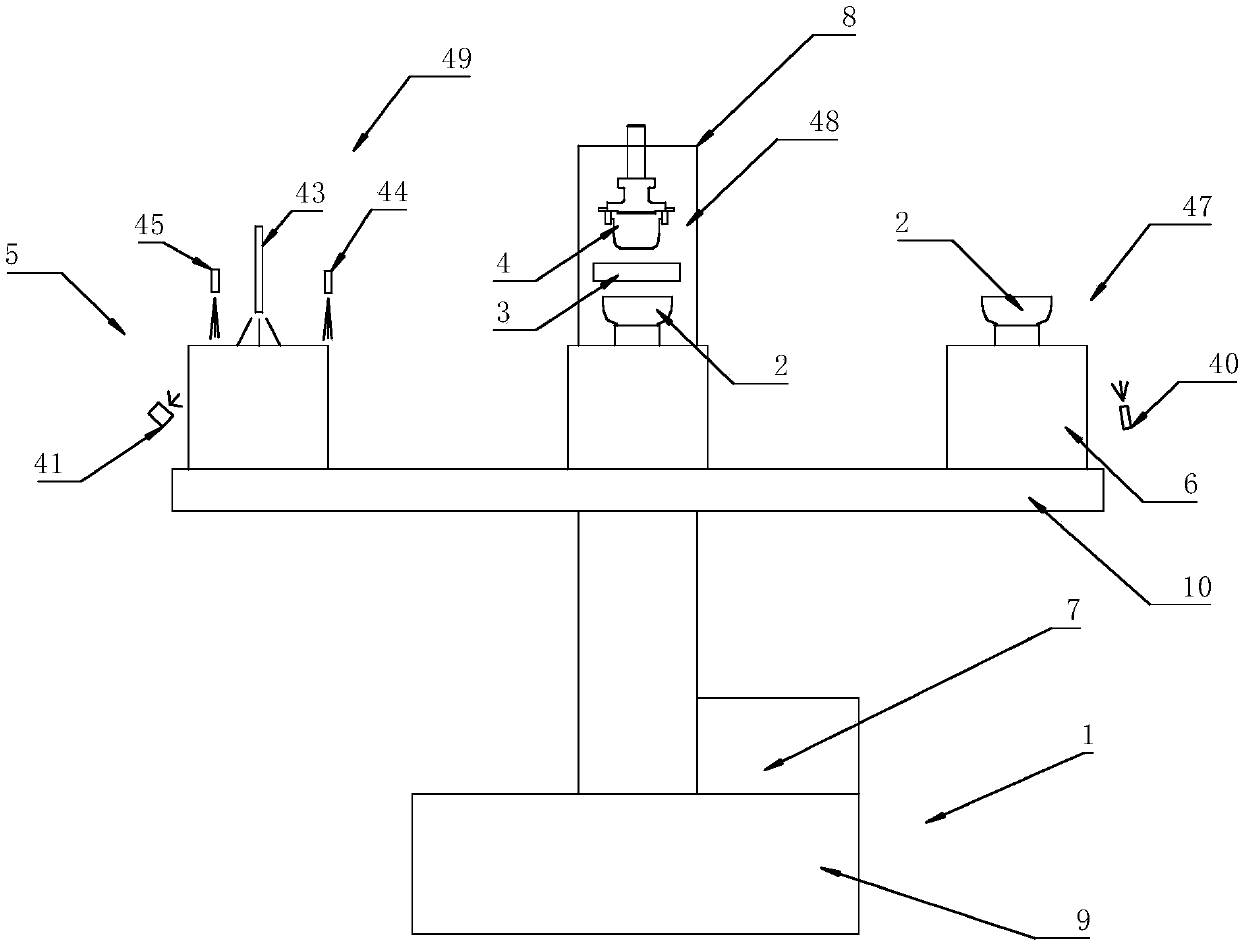

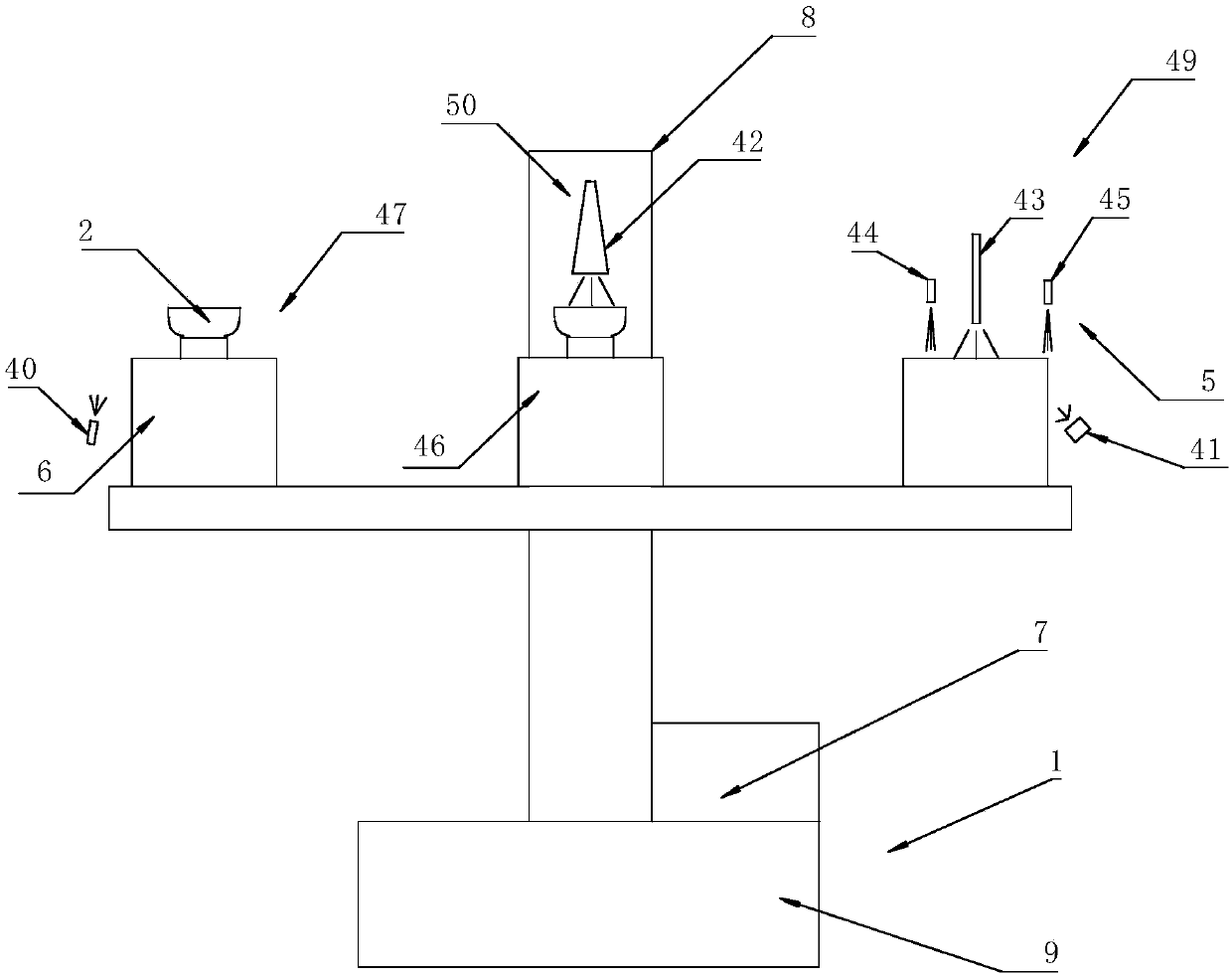

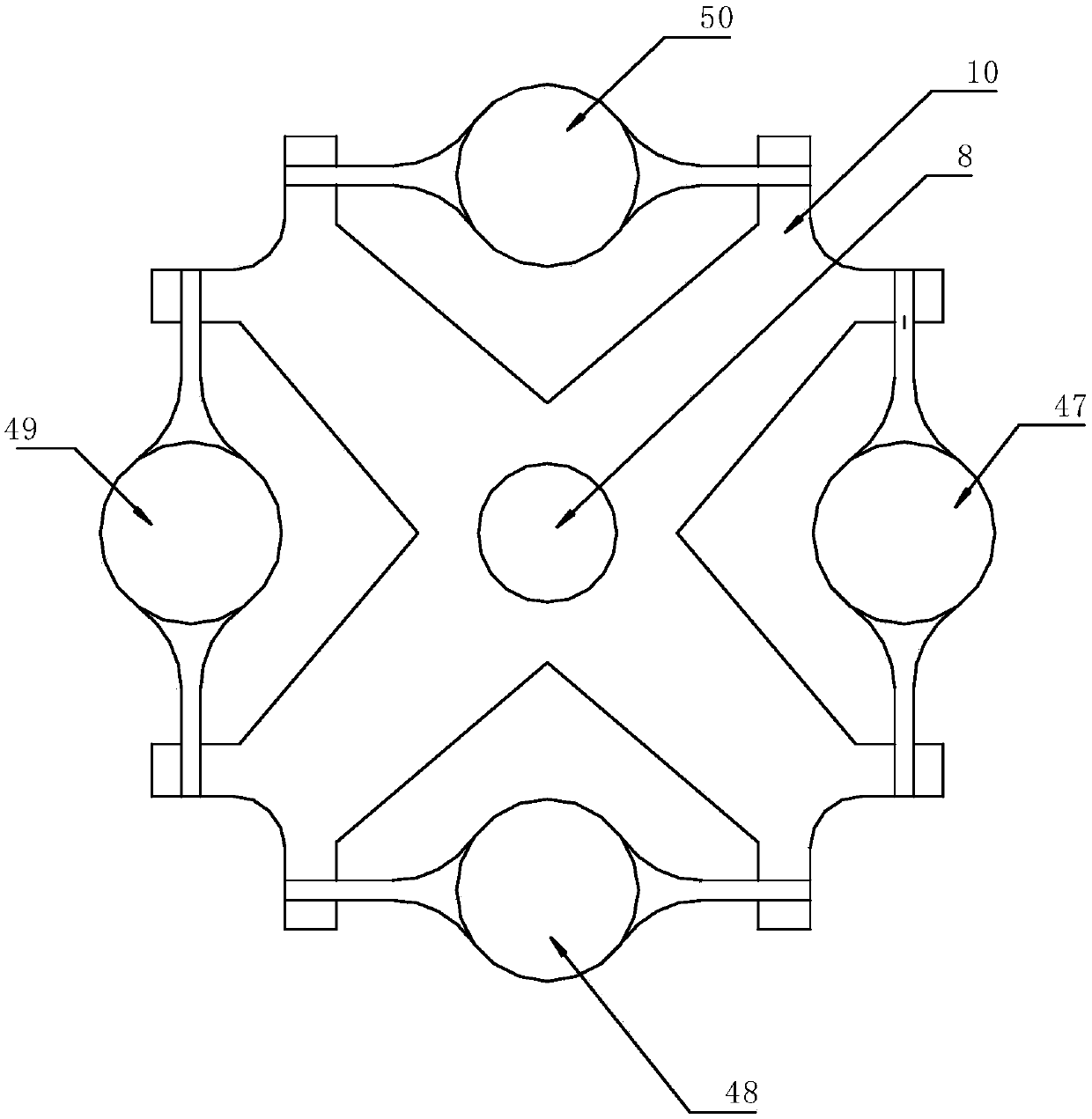

[0066] combine figure 1 , figure 2 and image 3 As shown, the glass molding device includes a rotating mechanism 1, a lower mold assembly 2, an upper mold assembly 4, a receiving station 47, a molding station 48, a cooling station 49 and a removal station 50;

[0067] The rotating mechanism 1 includes a rotating large disk 10 and a turntable drive device 7 for driving the rotating large disk 10 to rotate;

[0068] The material receiving station 47, the molding station 48, the cooling station 49 and the taking-out station 50 are set correspondingly to the rotating large plate 10 respectively;

[0069] The lower mold assembly 2 is arranged on the upper surface of the rotating large plate 10, and the lower mold assembly 2 can rotate with the rotating large plate 10 to the receiving station 47, the pressing station 48, the cooling station 49 and the removal station res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com