Novel constant temperature controllable film plating machine

A coating machine, constant temperature technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of cumbersome manufacturing process, short service life, high cost, and achieve simple design and structure realization, reduce Production difficulty and cost, effects that are easy to produce and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

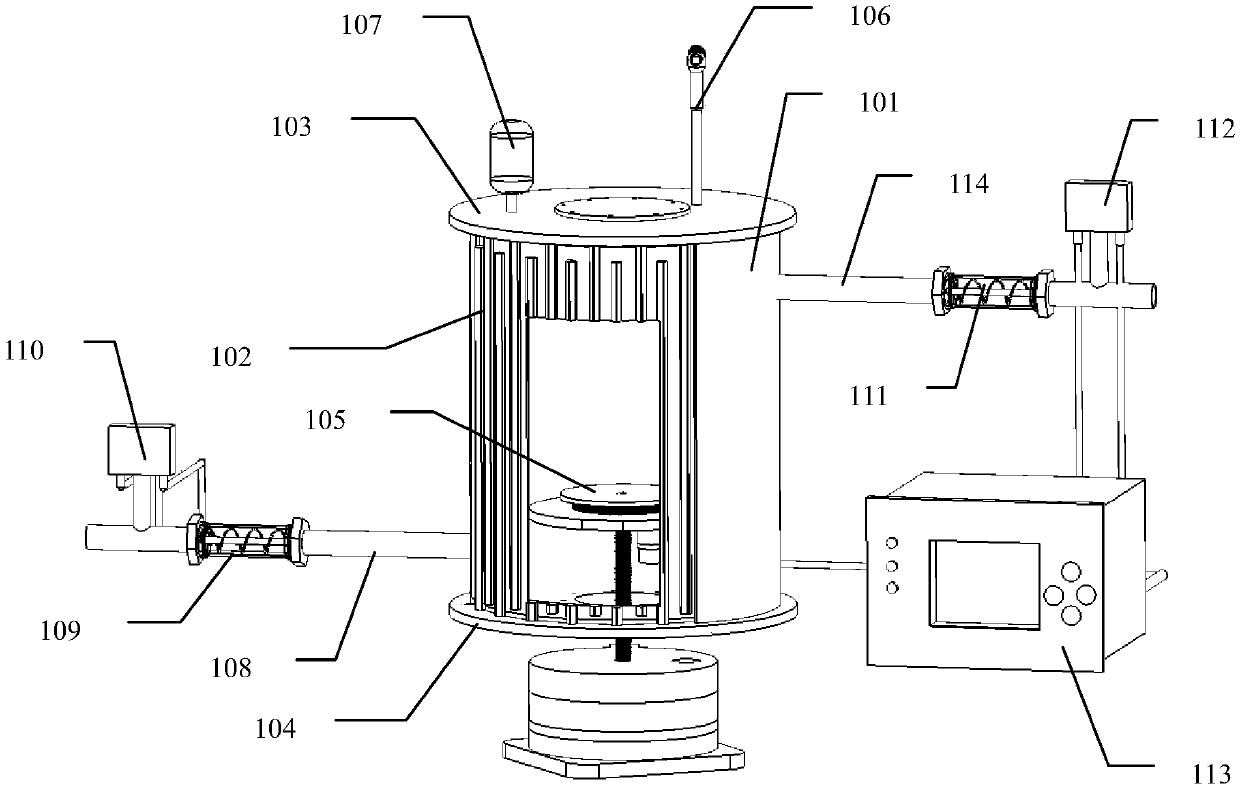

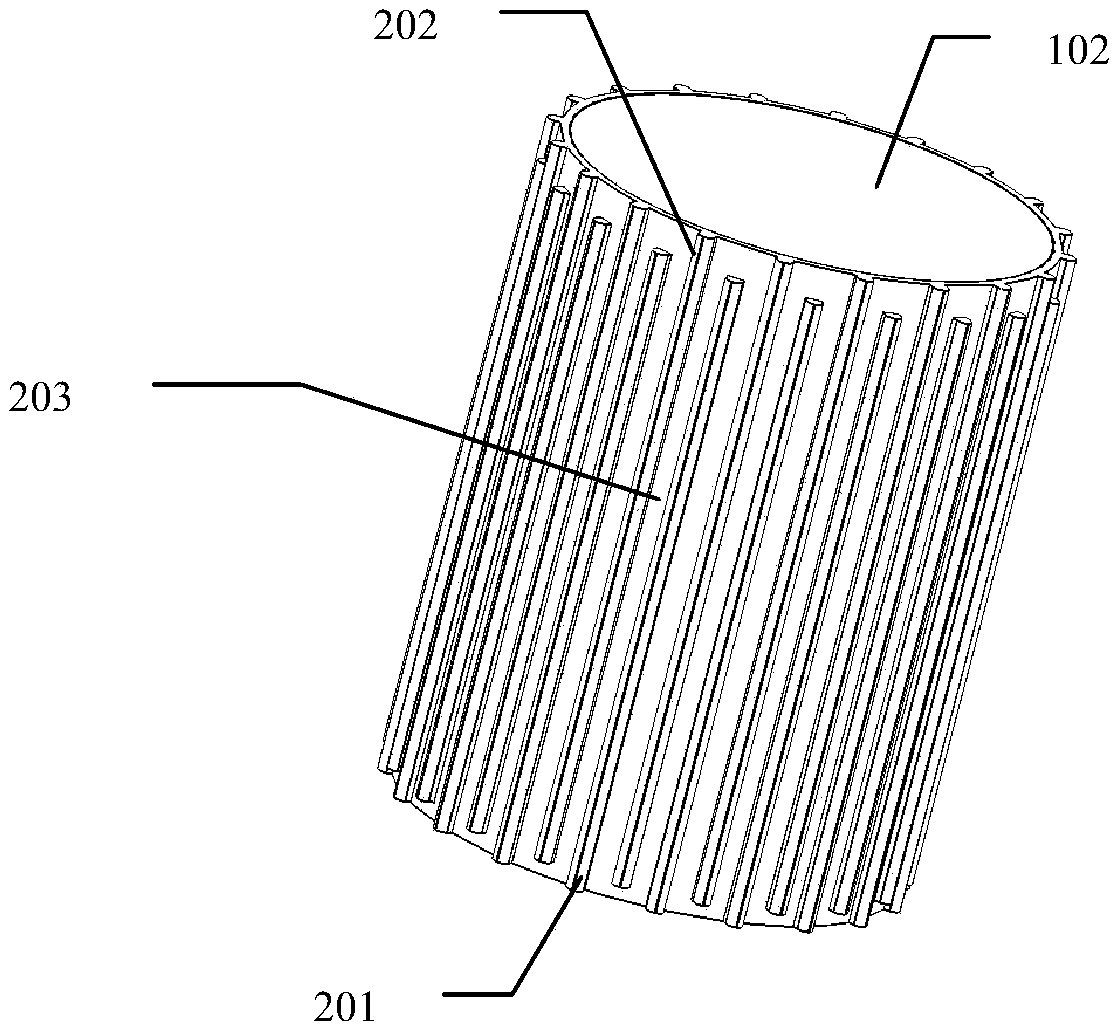

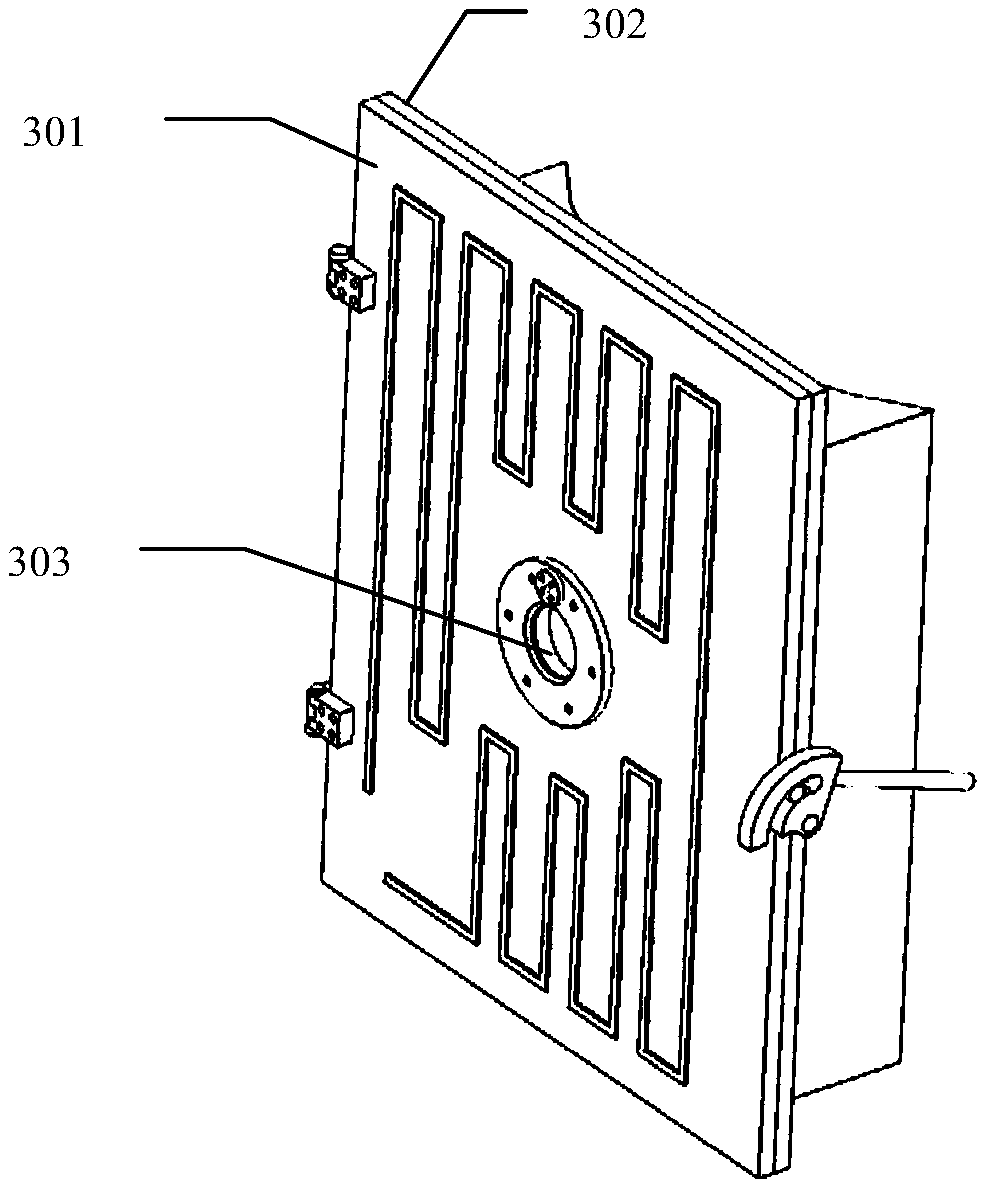

[0023] refer to Figure 1 to Figure 5 , the preferred embodiment of the present invention provides a new type of constant temperature controllable coating machine, comprising a vacuum furnace chamber and a workpiece table 105 inside thereof, the vacuum furnace chamber is composed of a furnace top 103, a furnace bottom 104, an inner cylinder 102 and an outer cylinder 101, the inner cylinder 102 is set inside the outer cylinder 101 and there is an interlayer space between the outer surface of the inner cylinder 102 and the inner surface of the outer cylinder 101, the top of the inner cylinder 102 and the outer cylinder 101 Sealed connection with the bottom surface of the furnace roof 103, and sealed connection between the bottom end and the top surface of the furnace bottom 104;

[0024] The interlayer space is provided with a plurality of alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com