Non-open excavation dismantling construction method for drilled underground structure

An underground structure and construction method technology, applied in building construction, building maintenance, construction and other directions, can solve the problems of long construction time, affecting traffic and environment, high demolition cost, short construction period, simple demolition construction method, and high demolition cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

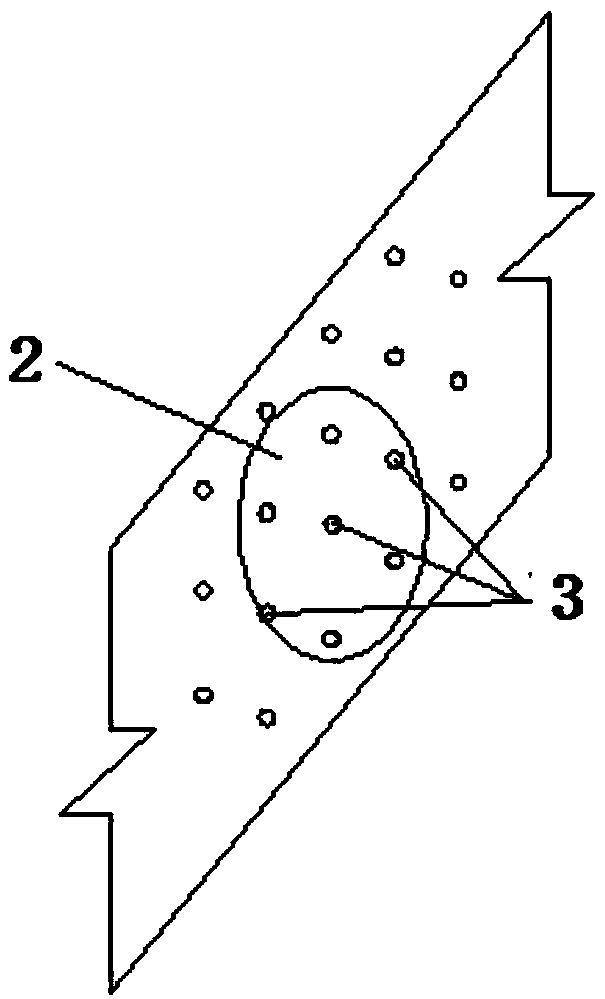

[0040] Embodiment one: if figure 1 As shown, the shield machine drills and crosses from the middle of culvert 1, and the specific removal method for the parts of the two sides of culvert 1 that are crossed by the shield machine is as follows:

[0041] Step 1. According to the drilling route of the shield machine, determine the specific position where both sides of the culvert 1 are crossed, that is, the position where the culvert body is crossed;

[0042] Step 2. Grouting to rock mass or soil mass

[0043] Grouting in the side rock mass: grouting reinforcement to the rock mass or soil body that is passed through the outer side of the culvert body 2, filling the gaps in the rock mass or soil body, and ensuring that the rock mass or soil mass that is passed through the outer side of the culvert body 2 has Certain self-stability; considering the actual construction error, appropriately expand the grouting range, and the grouting range extends 1 to 3 meters from the surrounding o...

Embodiment 2

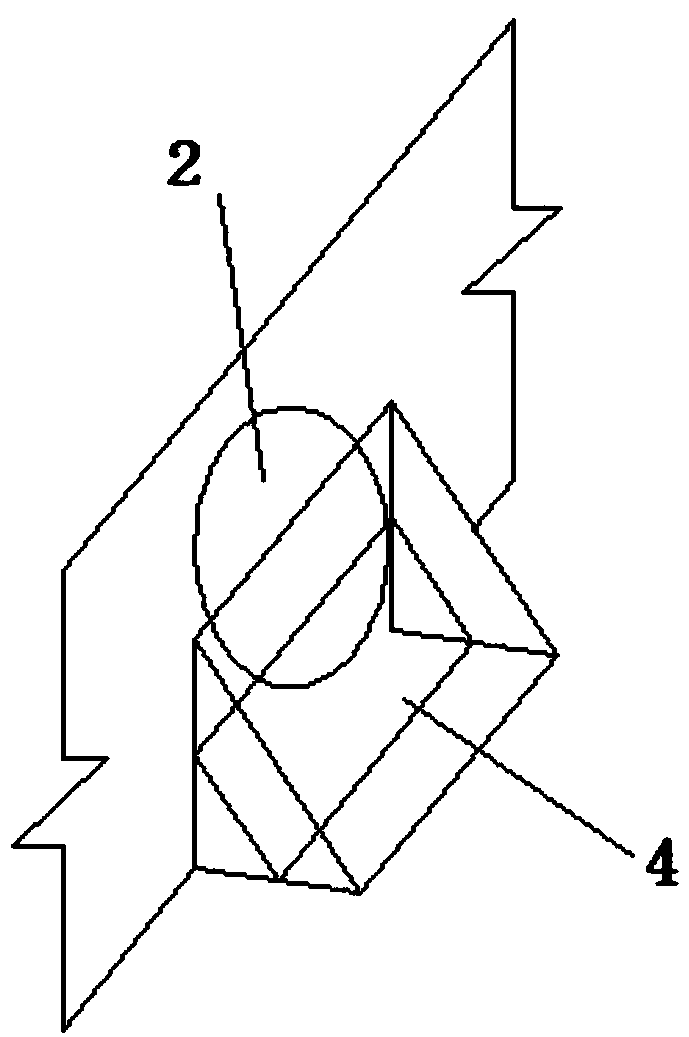

[0047] Embodiment two: if Figure 4 As shown, the shield machine passes through the upper part of the culvert 1, and the shield machine passes through the two sides and the top surface of the culvert 1. The specific removal method of the two sides and the top surface of the culvert 1 is as follows:

[0048] Step 1. According to the drilling route of the shield machine, determine the specific position where the two sides and the top surface of the culvert 1 are crossed, that is, the position where the culvert body 2 is crossed;

[0049] Step 2, grouting to rock mass or soil mass (such as Figure 5 shown)

[0050] Grouting in the side rock mass or soil body: extending 1 to 3 meters from the side crossed by the culvert body 2 to the surrounding, grouting in the rock mass outside the extension range and the rock mass outside the crossed culvert body 2;

[0051] Grouting in the rock mass or soil at the top: extending 1~3m from the top through the culvert 2 to the surrounding, gro...

Embodiment 3

[0057] Embodiment three: as Figure 7 As shown, the shield machine passes through the lower part of the culvert 1, and the specific removal method of the culvert body that is crossed on the two sides and the bottom of the culvert 1 is as follows:

[0058] Step 1. According to the drilling route of the shield machine, determine the specific position where the two sides and the bottom of the culvert 1 are crossed (that is, the specific position where the culvert body 2 is crossed);

[0059] Step 2. Grouting to rock mass or soil mass

[0060] Grouting in the side rock mass or soil body: extend 1-3 meters from the side crossed culvert to the surrounding, and grout in the rock mass outside the extension range and the rock mass outside the crossed culvert;

[0061] Step 3: Dismantle the crossed culvert by area and make support structure 4

[0062] (1) Demolition of the side of the culvert being crossed by the culvert: the removal method is the same as Step 3 of Embodiment 1;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com