Water bottom sludge sampling device driven by two positioning slide blocks

A sampling device and dual positioning technology, applied in sampling device, sampling, measuring device and other directions, can solve the problems that the sampling device cannot be fixed, the sample is easily disturbed, the sealing effect is not good, etc. Efficiency and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

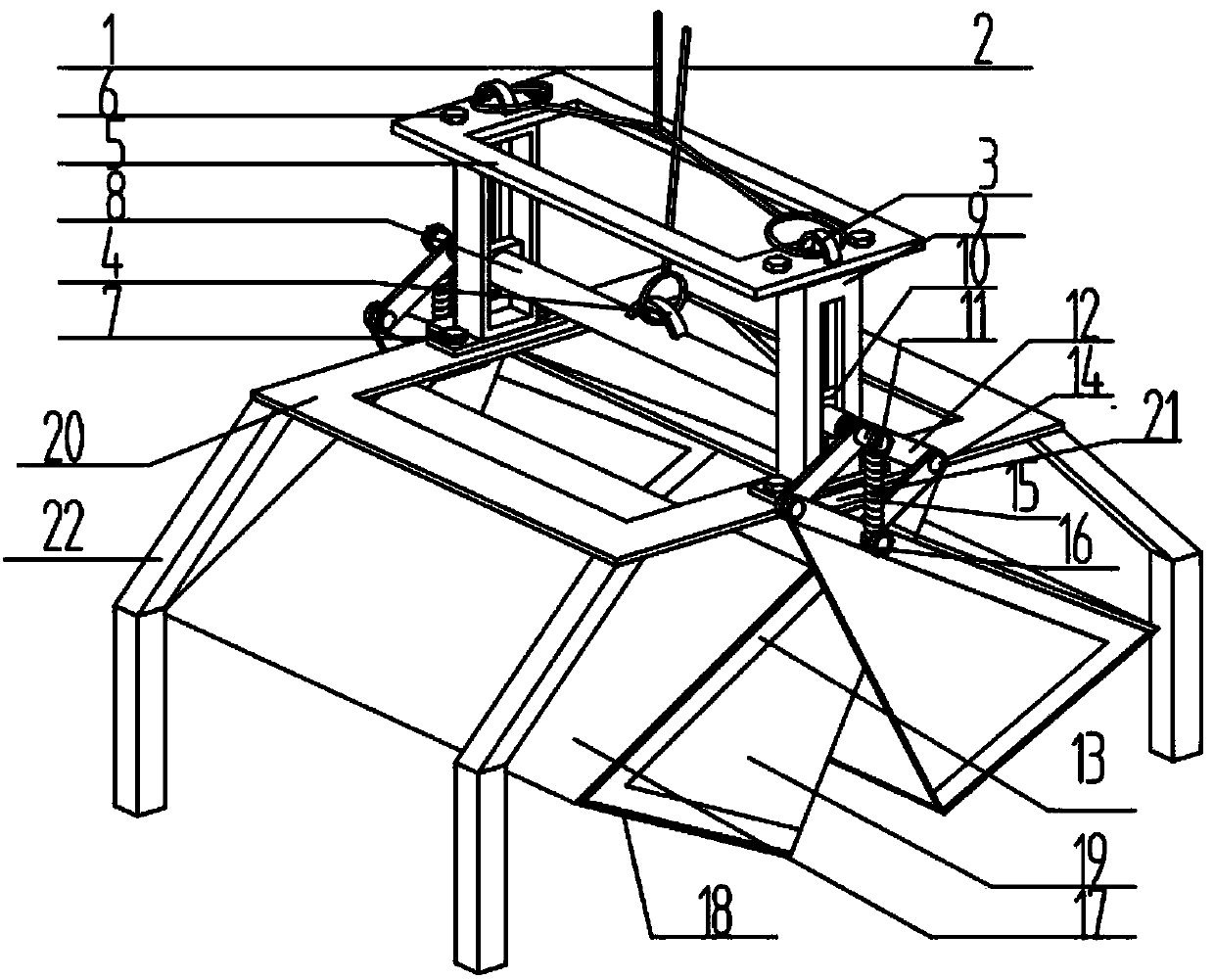

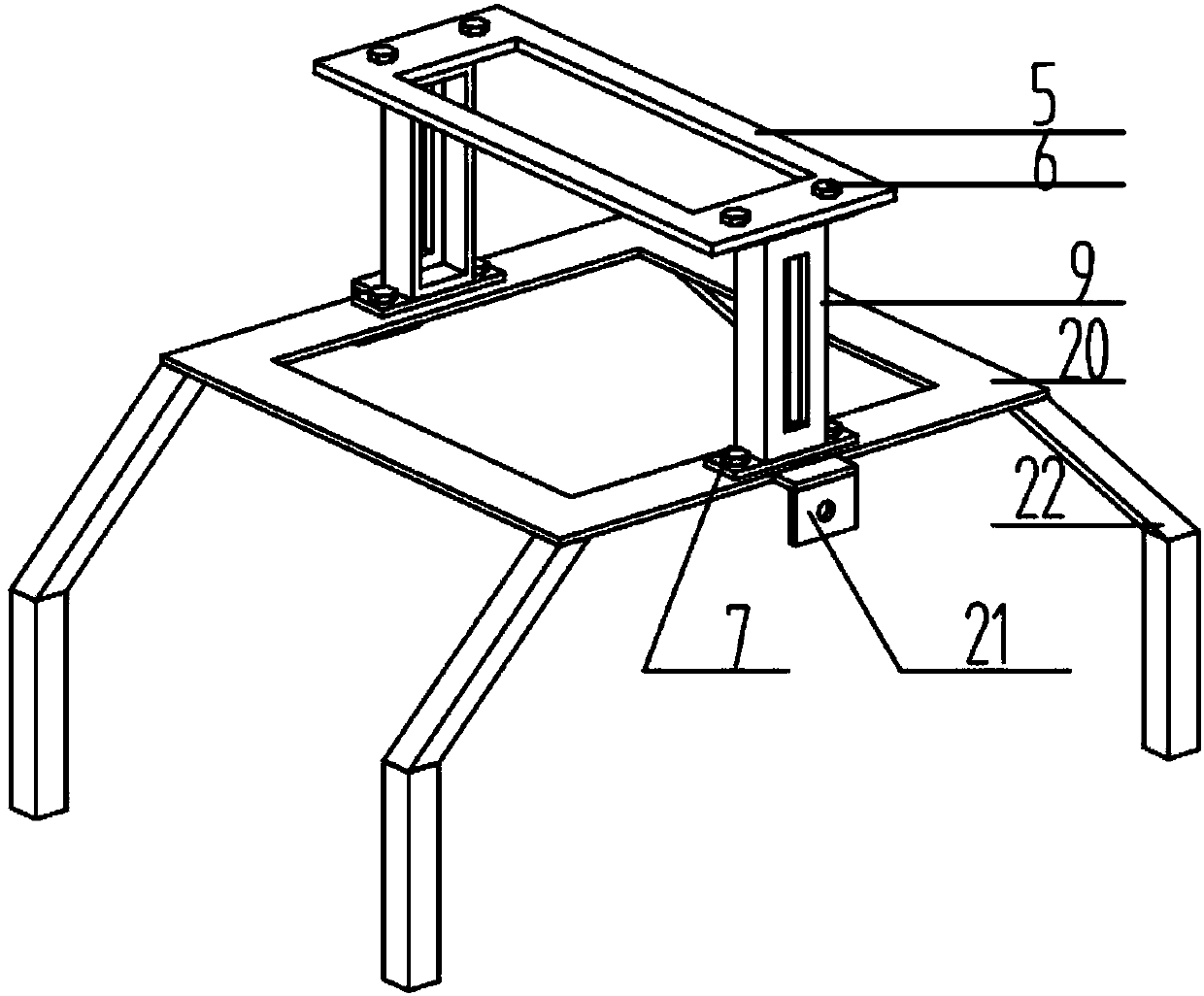

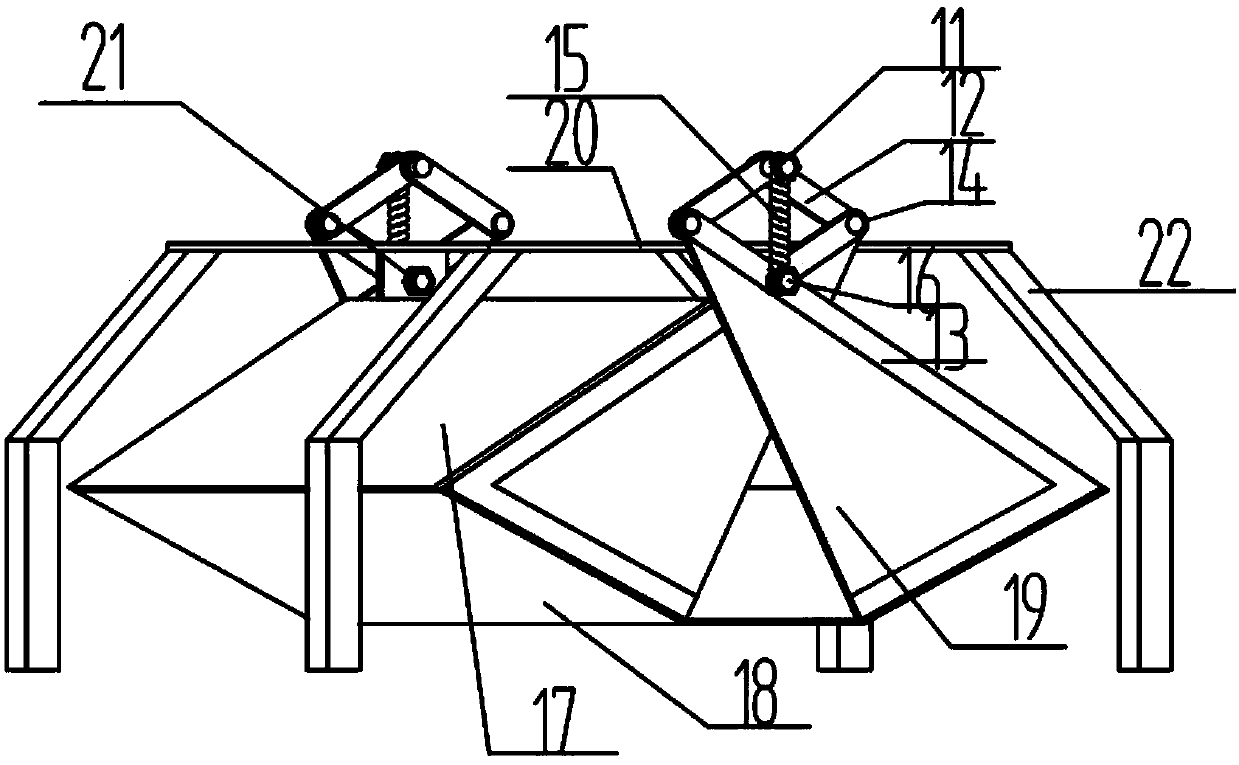

[0024] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0025] like Figure 1 to Figure 5 As shown, the dual-positioning slider-driven underwater mud sampling device of the present invention includes a power mechanism, a left and right side positioning mechanism, a bottom positioning mechanism and a bucket mechanism. The specific structure and connection method are:

[0026] The power mechanism includes a positioning upper plate 5, a first stay cord 1, a second stay cord 2, a first shackle 3, a second shackle 4 and a screw 8, the positioning upper plate 5 has a first shackle 3, The first stay cord 1 is set on the first shackle 3, the second shackle 4 is arranged on the screw rod 8, the second stay cord 2 is set on the second shackle 4, and the positioning upper plate 5 and the screw mandrel 8 can pass through the second shackle 4. A stay cord 1 and a second stay cord 2 are pulled up and down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com