Plastic thermal riveted assembly monitoring method and device

A monitoring device and hot riveting technology, which is applied in the direction of measuring devices, optical device exploration, and material analysis, can solve problems such as high surface quality requirements, product welding defect assembly quality, unclear edges between targets and backgrounds, etc., to improve production efficiency and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

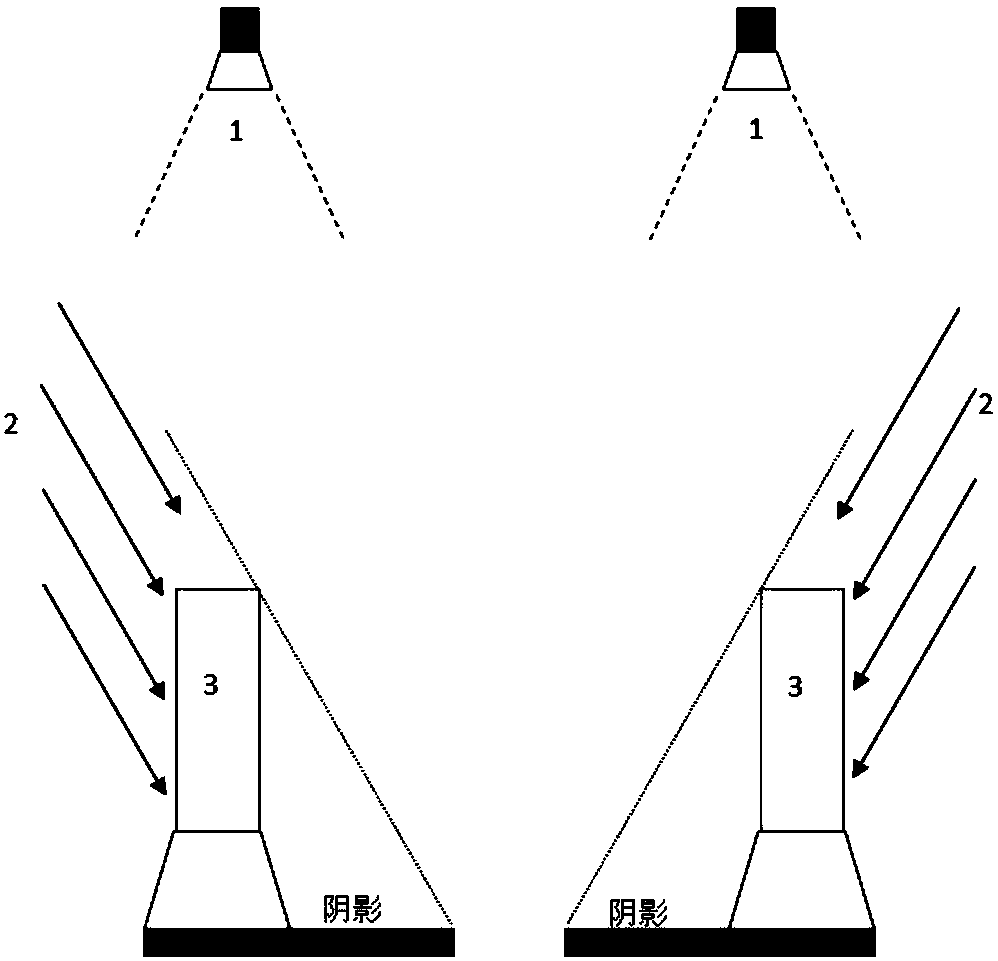

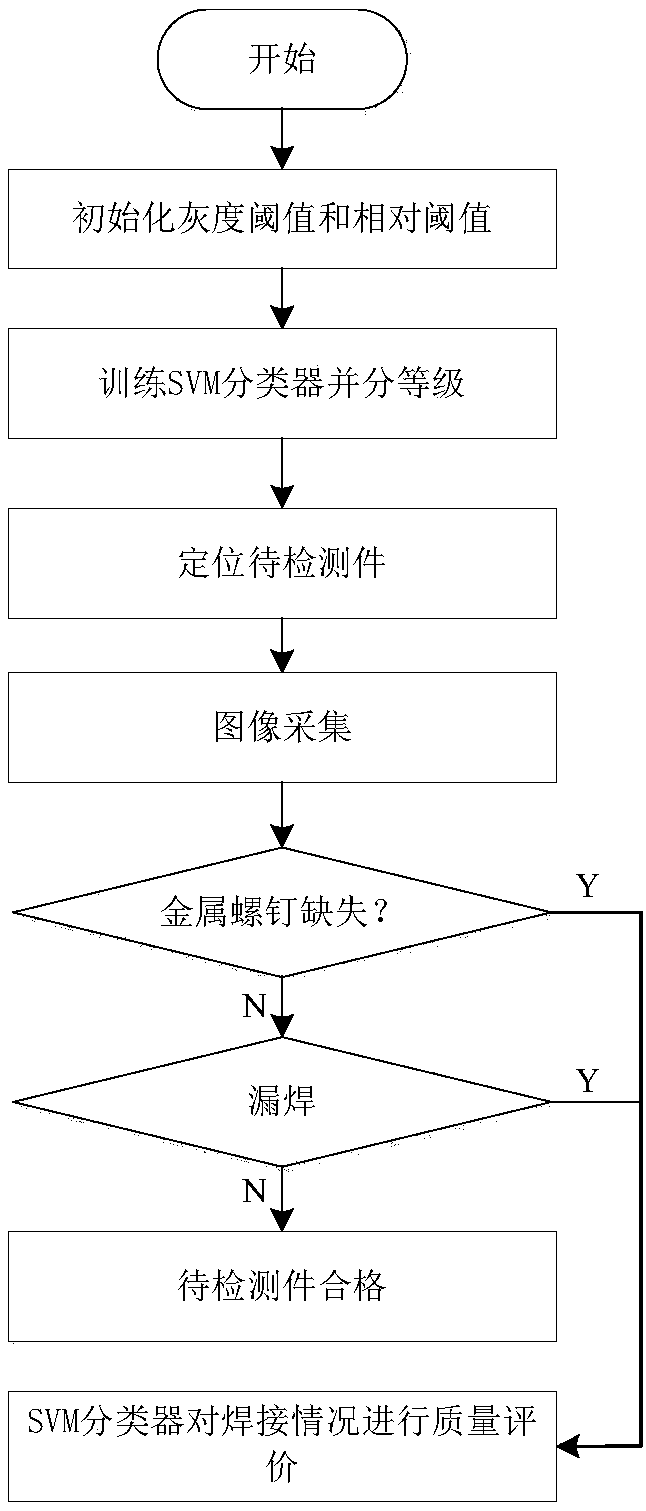

[0019] The plastic hot riveting assembly device includes a strong collimated light source module, a camera module, a system control module, and an auxiliary transportation and positioning module. It is used to form a specific shadow area for oblique riveting posts. In specific applications, multiple sets of strong collimated light source modules can be set according to needs. Different sets of strong collimated light source modules are arranged symmetrically in a ring; Appropriate object distance to photograph the welding column, where the object distance is determined by the selected lens and shooting resolution requirements; the system control module is used to control the light intensity and switch of the strong collimated light source, image acquisition cycle, auxiliary transport cycle, image analysis and Riveting quality judgment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com