Mobile phone screen

A mobile phone screen and adhesive layer technology, which is applied to the structure of telephones, electronic equipment, applications, etc., can solve the problems of affecting the normal use of users, increasing the cost of users, and the glass screen is easily broken, so as to achieve low production cost and excellent quality. Chemical resistance, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

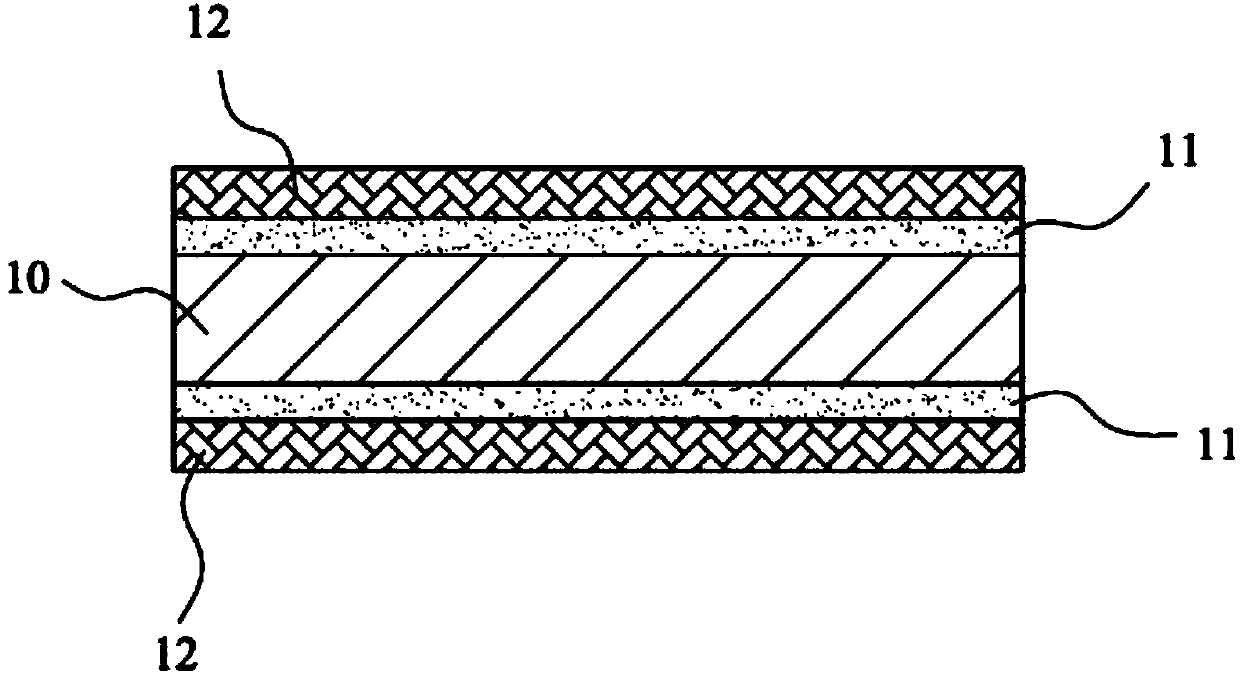

[0025] Such as figure 1 As shown, a mobile phone screen includes a plastic substrate layer 10, an adhesive layer 11 and a reinforcement layer 12. The plastic substrate layer 10 is made of plastic through secondary compression molding by injection molding. The adhesive layer 11 is soaked 1. Adhering closely to the surface of the plastic substrate layer 10 after the drying process, the strengthening layer 12 is the strengthening layer 12 that is tightly adhered to the surface of the adhesive layer 11 after the silicide is dried and hardened by ultraviolet rays. The thickness of the plastic substrate layer 10 is 0.1-1 mm, preferably 0.2-0.6 mm. The adhesive layer 11 has a thickness of 2-20 μm, preferably 3-10 μm. The strengthening layer 12 has a thickness of 3-10 μm, preferably 4-8 μm. It should be noted that the present invention can be used not only as a display screen of a mobile phone, but also as a protective screen of a mobile phone, and can also be used as a protective c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com