Copper and aluminum compound column wing radiator copper pipe expansion device and pipe expansion method

A technology of copper-aluminum composite and expansion tube device, which is applied in the field of machinery, can solve problems such as stress corrosion of copper tubes, shortened service life of radiators, and influence on heat transfer, and achieve expansion joint tightness design, reasonable expansion joint tightness, and easy to use Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

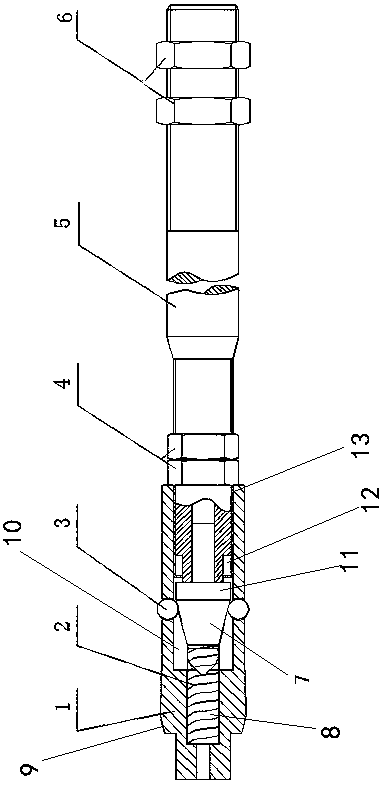

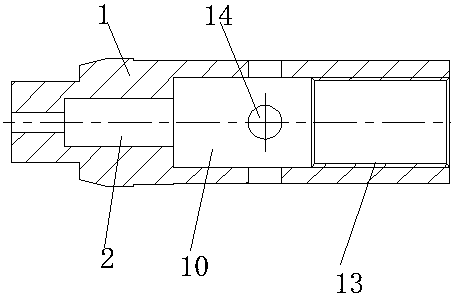

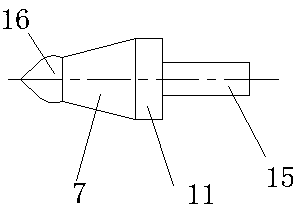

[0021] Such as figure 1 , 2 , 3, a copper tube expansion device for copper-aluminum composite column-wing radiators, including a pull rod 5 and an alloy pull head 1 connected to the pull rod 5, an expansion tube cavity 10 is arranged in the pull rod 5, and the expansion tube cavity 10 is arranged in the pull rod 5. A tube expansion device is provided in the tube cavity 10, and at least one tube expansion hole 14 communicating with the tube expansion cavity 10 is opened in the middle of the tie rod 5, and a steel ball matched with the tube expansion device is installed in the tube expansion hole 14 3.

[0022] The tube expansion device includes a spring 2 installed inside the expansion tube cavity 10, one side of the spring 2 is provided with an alloy cone 7, one side of the alloy cone 7 is connected to a limiting cone ring 11, and the limiting cone ring 11 An adjusting bushing 13 is installed on one side of the pull rod 5, and one end of the pull rod 5 is movably installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com