Side bearing and preparation method thereof

A side bearing box and metal plate technology, which is applied in the direction of the device that moves relative to each other laterally between the underframe and the bogie, can solve the problems of stress concentration on the bonding surface between metal and rubber, large stiffness variation with temperature, side bearing Unstable friction torque and other problems, to achieve the effect of suppressing snaking motion, solving frictional resistance torque and large wear, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

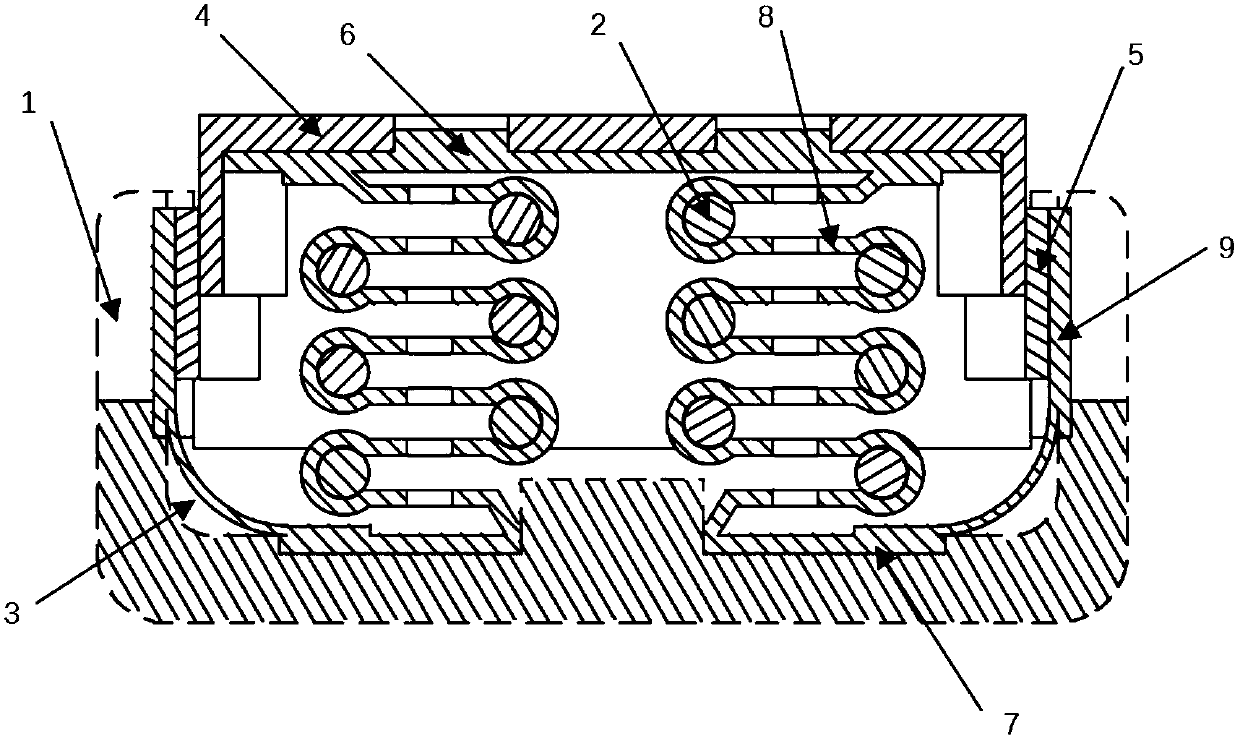

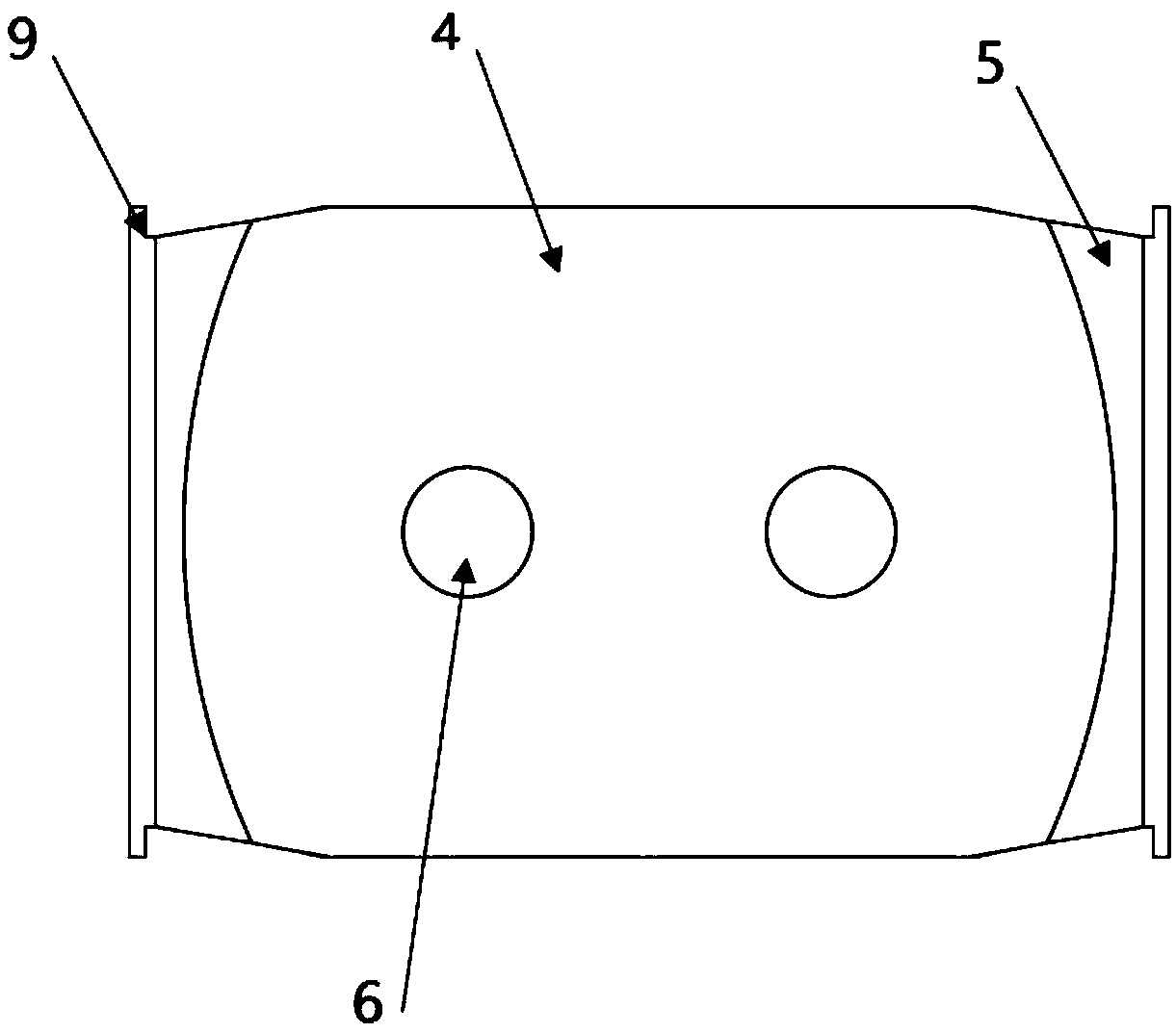

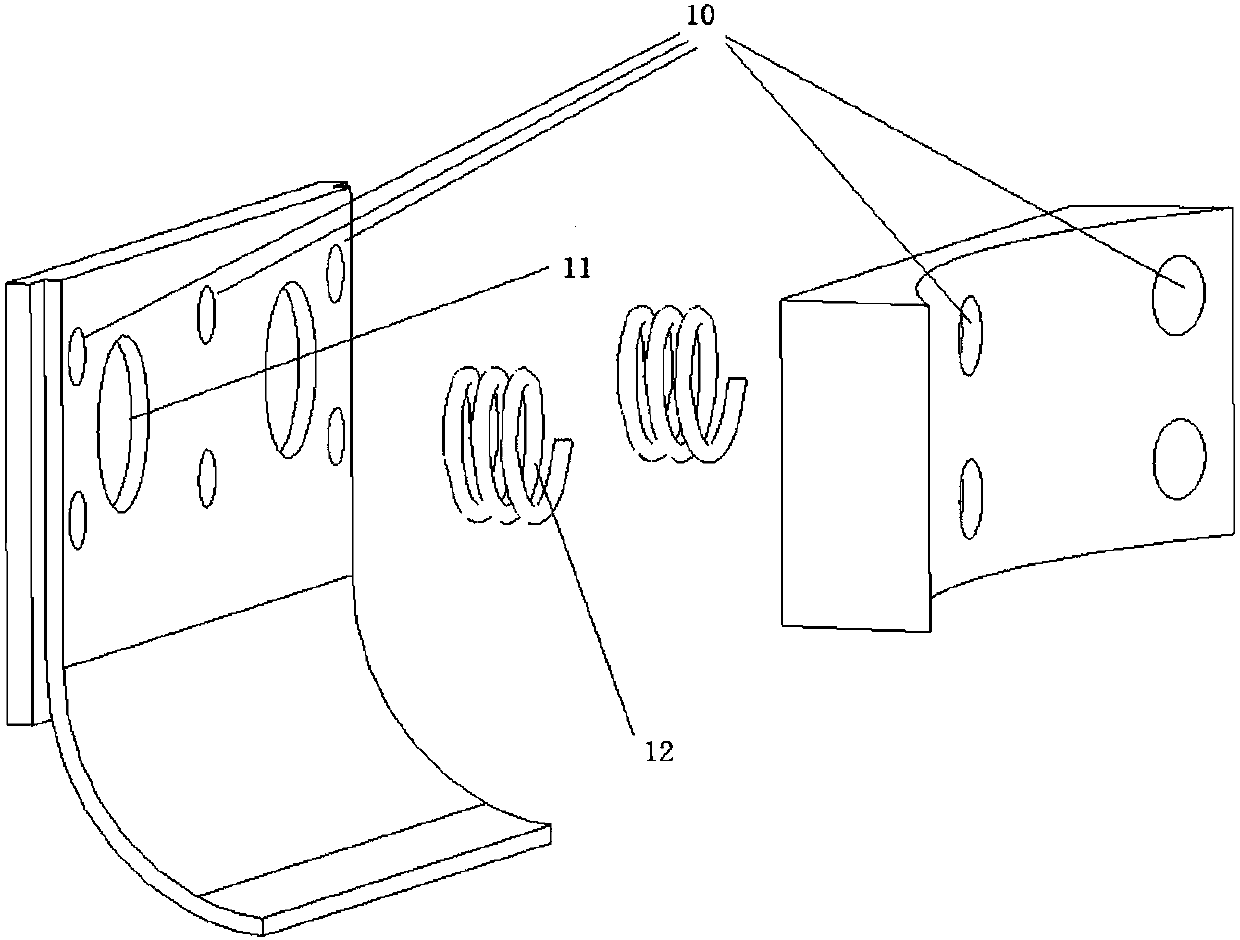

[0026] Such as Figure 1-2 As shown, the elastic side bearing includes a side bearing box 1, and the side bearing box 1 is equipped with a side bearing packaging frame 3 and a side bearing elastic assembly. The side bearing packaging frame includes a base 7, a main body upper plate 6 and a main body side ear 9. The side bearing elastic The component is assembled between the base 7 and the main body upper plate 6, and the side bearing elastic component includes two multi-layer S-shaped metal plates 8, the materials and layers of the two S-shaped metal plates 8 are the same, and the two S-shaped metal plates 8 are arranged anti-symmetrically. The two metal plates 8 are positioned by the bosses provided on the base 7. The transition arc of the first layer of each S-shaped metal plate is located away from the bosses. This arrangement can effectively save space. The number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com