Module for forming bending body of glass milk bottle

A technology for forming molds and baby bottles, which is applied in the field of glass bottle body forming molds and glass baby bottle curved body forming modules. It can solve problems such as single function, inability to cool, and high temperature requirements, and achieve firm installation, quality improvement, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

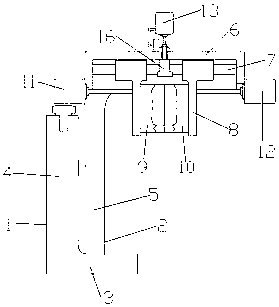

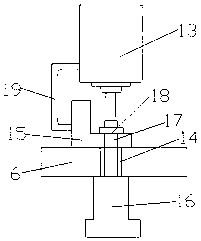

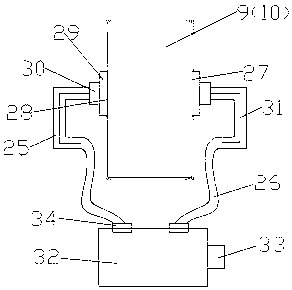

[0021] Such as figure 1 As shown, a glass feeding bottle curved body forming module includes a fixed seat, an inner mold, an outer mold, a cylinder and a water circulation system. The fixed seat includes a base 1 and a base 2. The base 1 is L-shaped and includes Bottom plate 3 and side plate 4, described base body comprises mutually perpendicular support plate 5 and top plate 6, and described support plate 5 is vertically arranged on described bottom plate 3, and described top plate 6 is provided with guide bar 7 below, and described guide bar 7 is covered with two ear plates 8, and the inner mold includes two mold cavities, a left mold cavity 9 and a right mold cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com