Cross-shaped full flow feeler inspection probe used for marine ultra-soft soil in-situ test

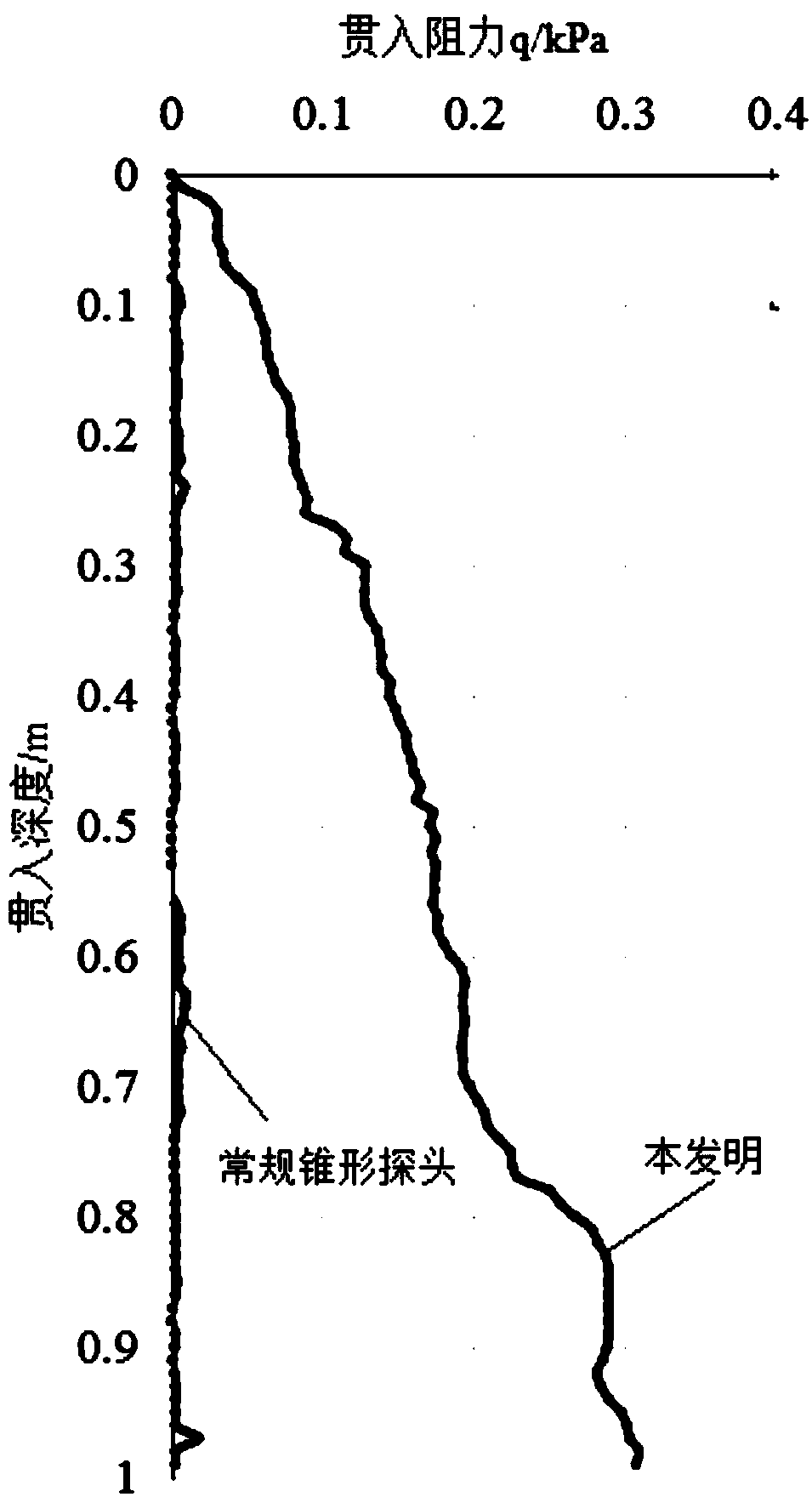

An in-situ testing and ultra-soft soil technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problem of difficult to accurately obtain physical and mechanical property indicators, small end resistance and end resistance changes, and difficult to accurately measure To achieve the effect of facilitating the flow around the soil, amplifying the end resistance and the change value of the end resistance, and enlarging the area of the probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

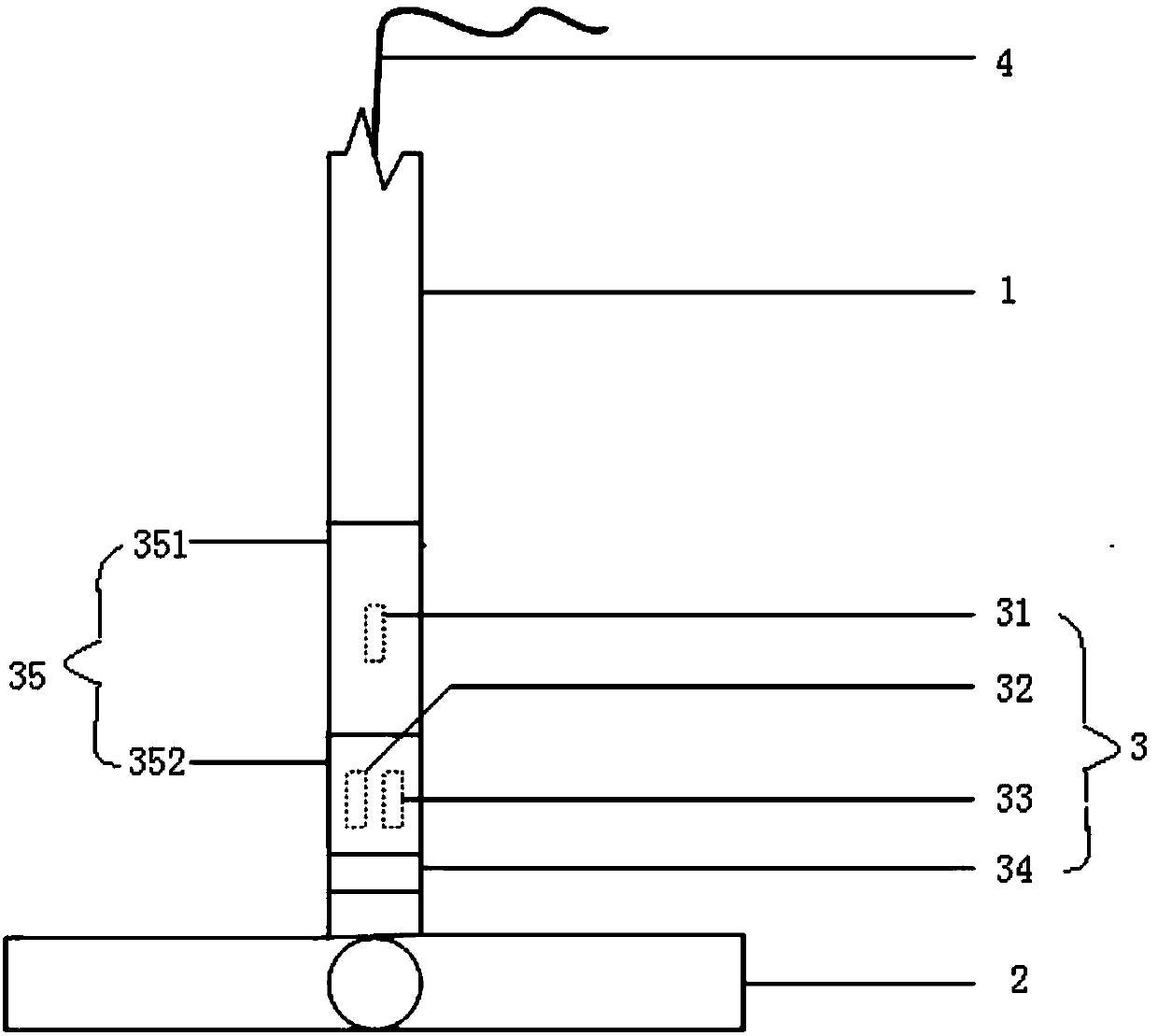

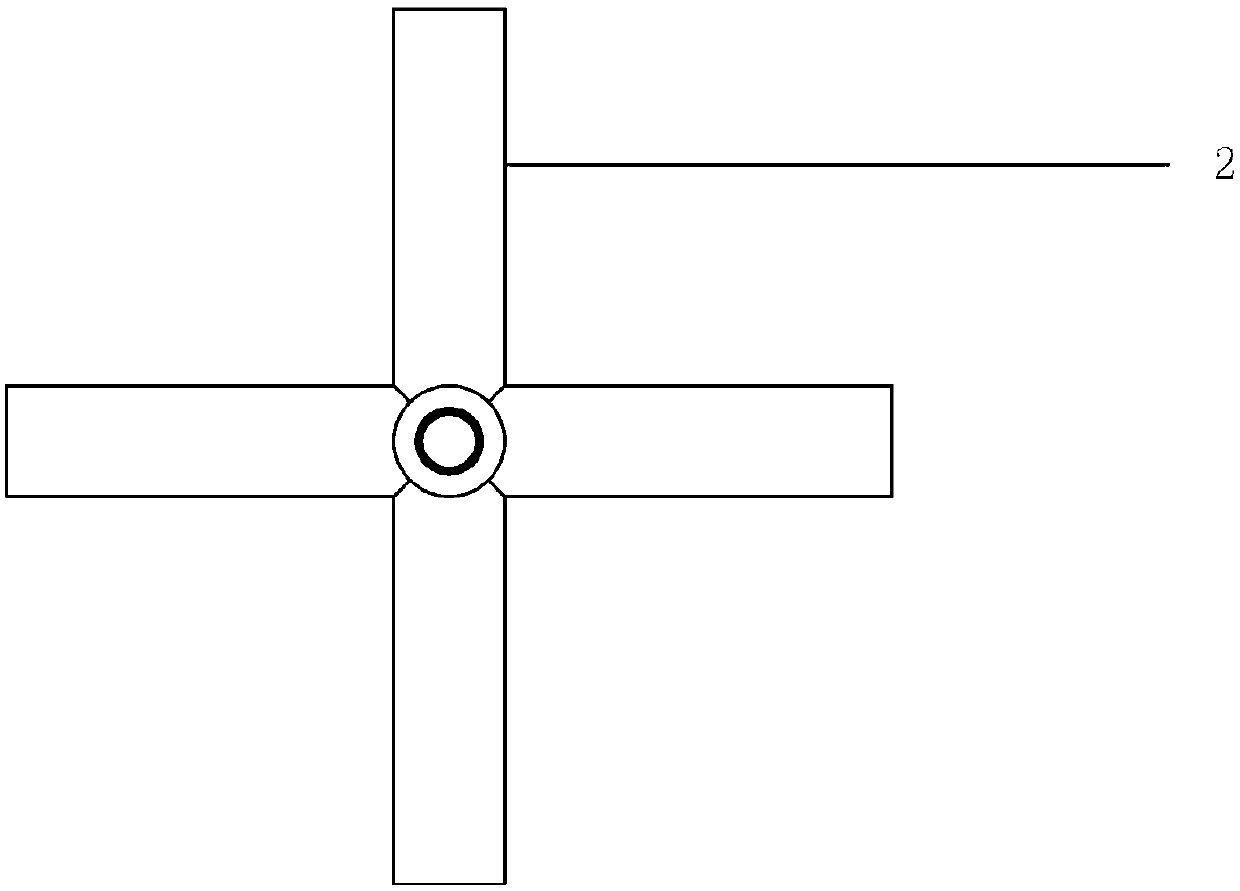

[0027] figure 1 It is a structural schematic diagram of the present invention, figure 2 yes figure 1 The top view of , the names of the parts marked in the figure are: probe rod 1, probe end 2, test system 3, friction pressure sensor 31, end resistance pressure sensor 32, pore water pressure sensor 33, pore pressure filter ring 34, sleeve 35, friction sleeve 351, end resistance sleeve 352, signal transmission line 4.

[0028] It can be seen from the accompanying drawings that the cross-shaped full-flow penetrating probe used for in-situ testing of marine ultra-soft soil is characterized in that it includes a test system and a probe end, and the probe end is vertically fixed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com