Moisture-proof carbon molecular sieve conveying device

A conveying device, carbon molecular sieve technology, applied in drying gas arrangement, progressive dryer, drying of solid materials, etc., can solve the problems of inability to sieve debris, product quality decline, inability to prevent product moisture absorption, etc., to maintain product quality , The effect of preventing sifting of debris and facilitating packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

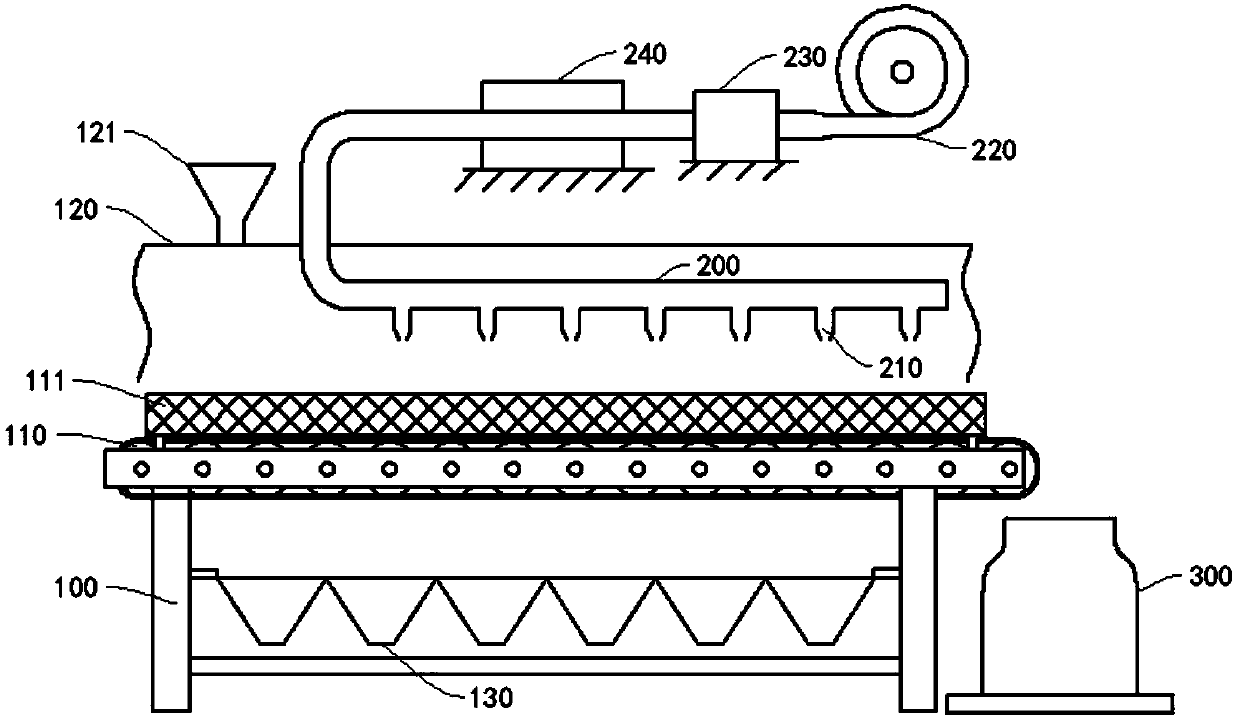

[0016] Example: The anti-hygroscopic carbon molecular sieve conveying device is composed of figure 1 As shown, it includes a support frame 100, a conveyor belt 110 is arranged on the support frame 100, an air supply duct 200 is arranged above the conveyer belt 110, and an air nozzle 210 is arranged on the air supply duct 200, and the pipeline of the air supply duct 200 is arranged along the air flow. A fan 220, a drying device 230 and a heating device 240 are arranged in sequence in the direction; a cover body 120 is arranged above the air supply duct 200, and the cover body 120 is provided with a feeding hopper 121 at the starting end of the conveying direction; the conveying The end of the belt 110 in the transport direction is provided with a packaging tub 300 .

[0017] The air flow direction of a section of the air supply duct 200 provided with the air nozzles 210 is the same as the conveying direction of the conveyor belt 110 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com