Coating thickness automatic detection equipment

A technology for automatic detection and coating thickness, which is applied in the direction of measuring devices, instruments, and the use of wave/particle radiation, etc., can solve the problems of high price and application restrictions, and achieve low cost, stable and reliable performance, good promotion and application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

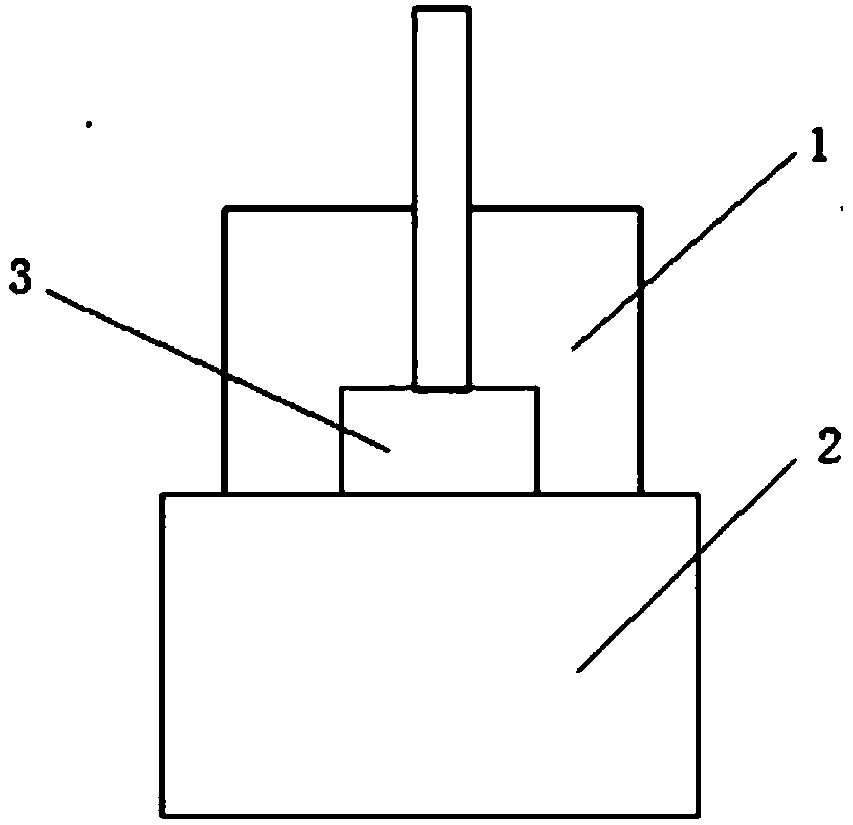

[0012] In order to further illustrate the technical solution provided by the present invention, a detailed description will be made below in conjunction with specific embodiments and the accompanying drawings of the description.

[0013] Such as figure 1 As shown, the present invention includes a ball mill rotating device, a diamond particle abrasive drop point system, a sample holding device and a detection device. The ball mill rotating system uses a high-speed DC motor as a power output to drive the drive shaft to rotate. The diamond particle abrasive drop point system controls the low-speed DC motor through a single-chip microcomputer to realize the shaking and rotating drop point of the diamond particle abrasive agent bottle. The sample clamping device can be rotated 360° and adjusted up and down to realize ball milling at different positions of the sample. The whole ball milling process is done automatically.

[0014] When working, in the first step, the grinding ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com