Lithium ion battery cycle life detection device and lithium ion battery cycle life assessment method

A lithium-ion battery, cycle life technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low accuracy of test results and complex evaluation methods, and achieve simple process, simple evaluation method and adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

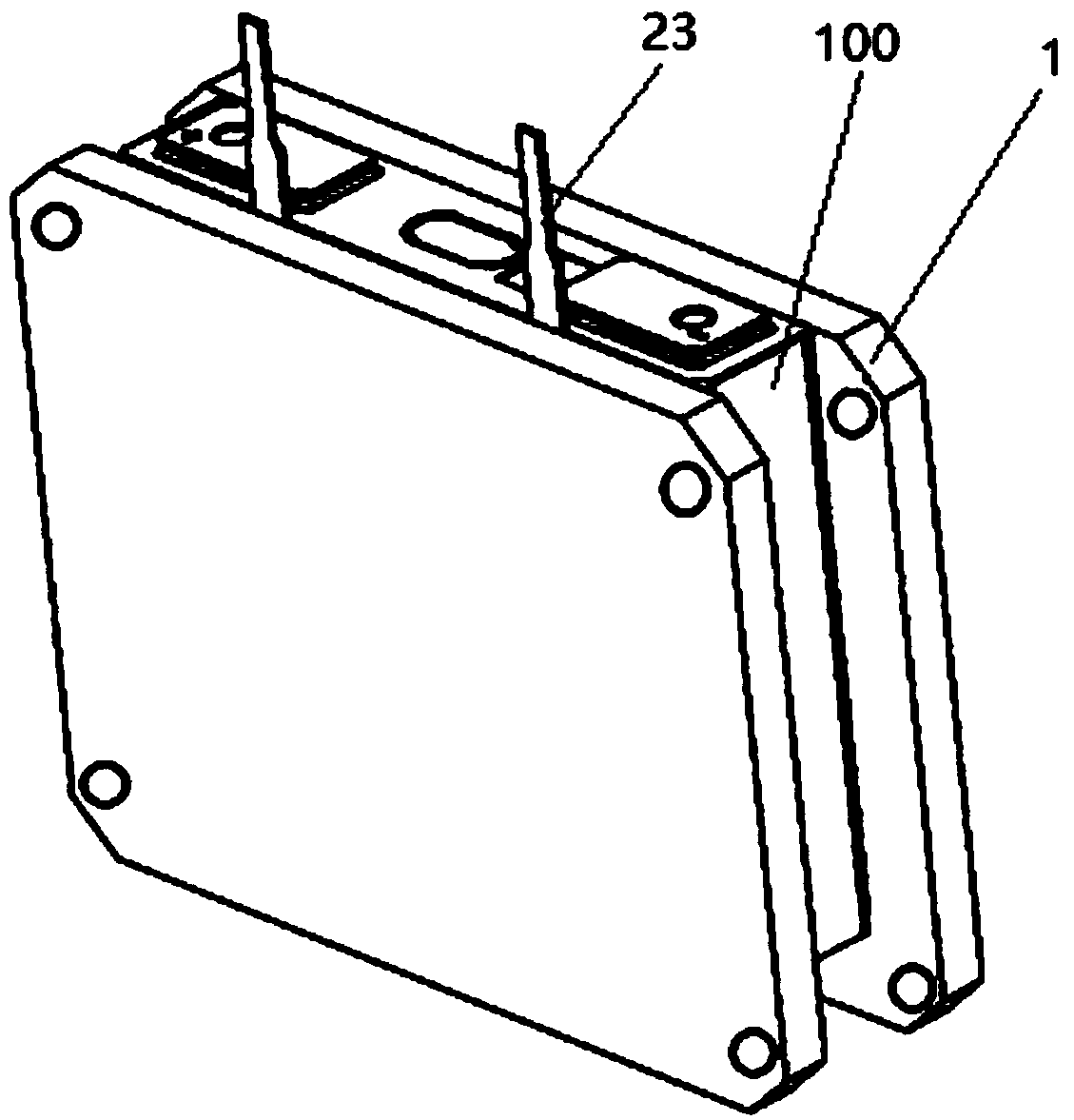

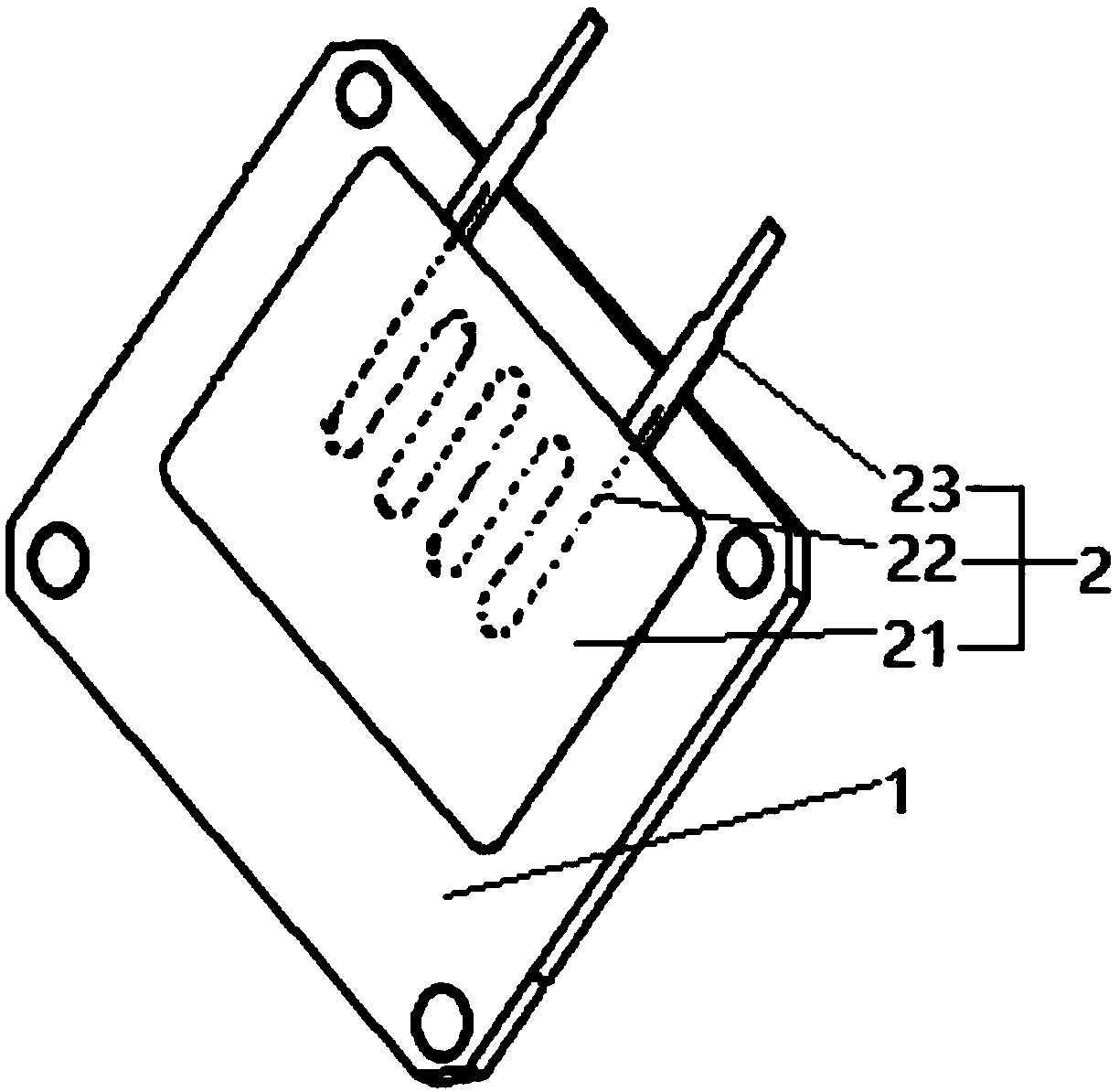

[0031] see figure 1 and figure 2 , a detection device for the cycle life of a lithium-ion battery, comprising two base plates 1 and a pressure sensor 2, the two base plates 1 are arranged in parallel, the lithium-ion battery 100 to be tested is located between the two base plates 1, and the two base plates 1 are connected by fasteners A base plate 1 and the lithium-ion battery 100 to be tested are fastened and arranged; the pressure sensor 2 is installed on the side of the base plate 1 opposite to the lithium-ion battery 100 to be tested, and the output end of the pressure sensor 2 is electrically connected to the signal processor (in the figure). not shown). The pressure sensor 2 can be located on a side of one bottom plate 1 opposite to the lithium-ion battery 100 to be tested, or on two sides of the bottom plate 1 opposite to the lithium-ion battery 100 to be tested. In this embodiment, the pressure sensor 2 is located on a side of the bottom plate 1 opposite to the lith...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 lies in the structure of the pressure sensor 2 . In this embodiment, the thickness of the elastic sensitive element 21 is 0.04mm. The resistance value of the wire strain gauge is 200MΩ. The diameter of the wire strain gauge is 0.035mm.

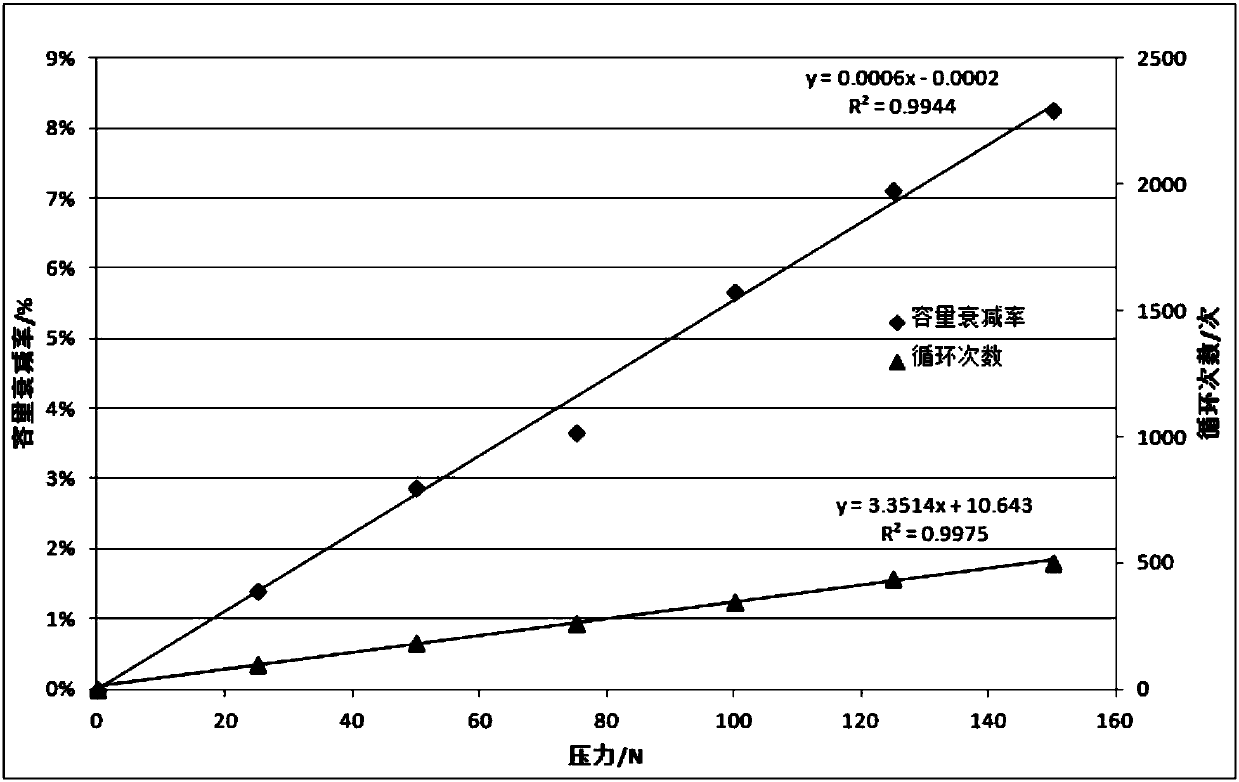

[0045] In this example, taking a square lithium-ion battery to be tested as an example, the charge-discharge cycle performance test is carried out. The cycle test condition is 25°C and 1C / 1C rate for cycle charge-discharge experiments, and the charge-discharge mode is constant current constant voltage charge-hold-constant Current discharge, the charge cut-off voltage is 4.2V, the discharge cut-off voltage is 2.8V, and the rest time is 10min. The test equipment used is the constant wing charge and discharge test cabinet. The number of cycles is 1500 times. The relationship between the voltage of the pressure sensor obtained in this embodiment and the capacity decay rate of the li...

Embodiment 3

[0050] The difference between this embodiment and Embodiment 1 lies in the structure of the pressure sensor 2 . In this embodiment, the thickness of the elastic sensitive element 21 is 0.05mm. The resistance value of the wire strain gauge is 200MΩ. The diameter of the wire strain gauge is 0.05mm.

[0051] In this example, taking a square lithium-ion battery to be tested as an example, the charge-discharge cycle performance test is carried out. The cycle test condition is 25°C and 1C / 1C rate for cycle charge-discharge experiments, and the charge-discharge mode is constant current constant voltage charge-hold-constant Current discharge, the charge cut-off voltage is 4.2V, the discharge cut-off voltage is 2.8V, and the rest time is 10min. The test equipment used is the constant wing charge and discharge test cabinet. The number of cycles is 2500 times. The relationship between the voltage of the pressure sensor obtained in this embodiment and the capacity decay rate of the lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com