Industrial process fault diagnosis method based on similarility local spline regression

A technology for industrial process and fault diagnosis, which is applied to computer parts, complex mathematical operations, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

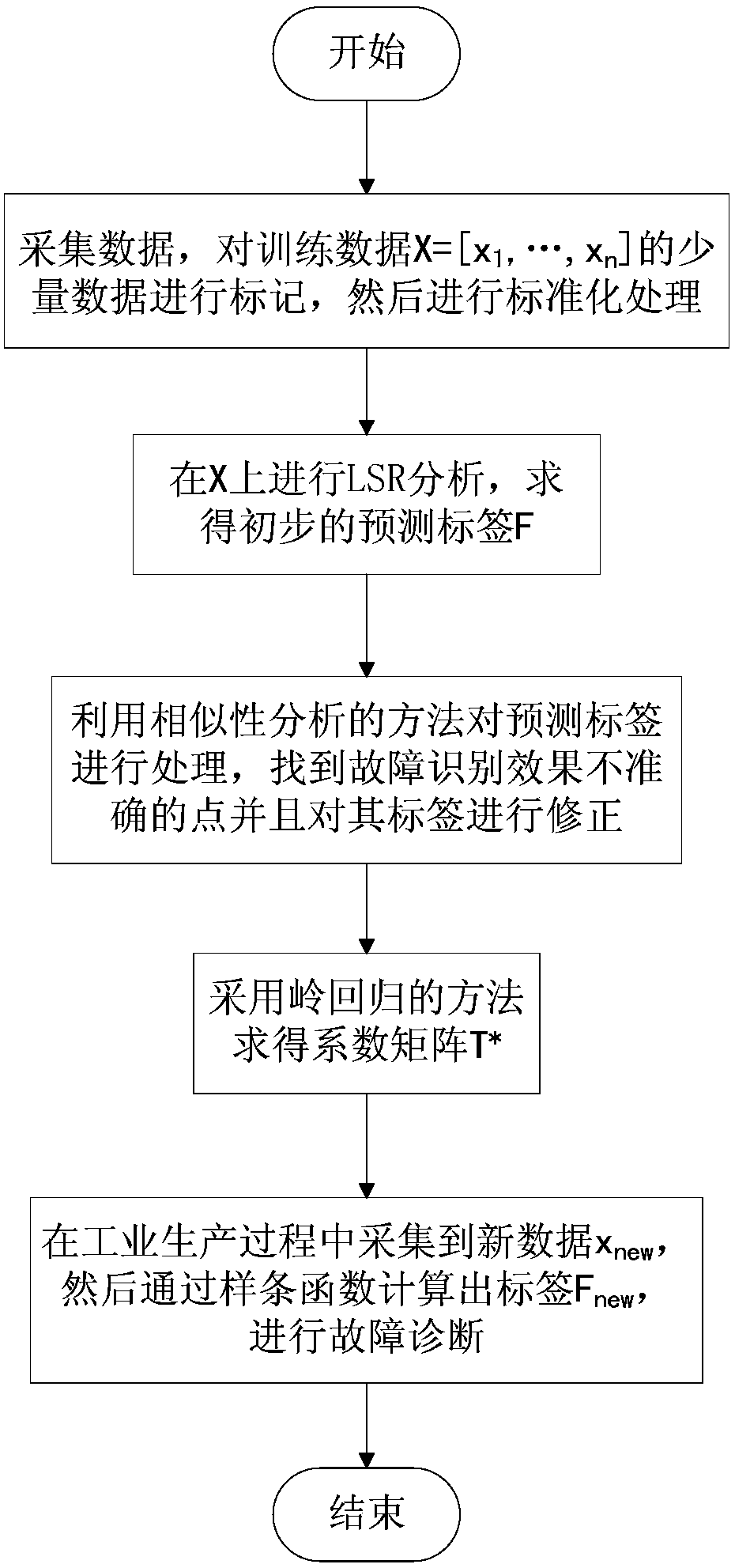

Method used

Image

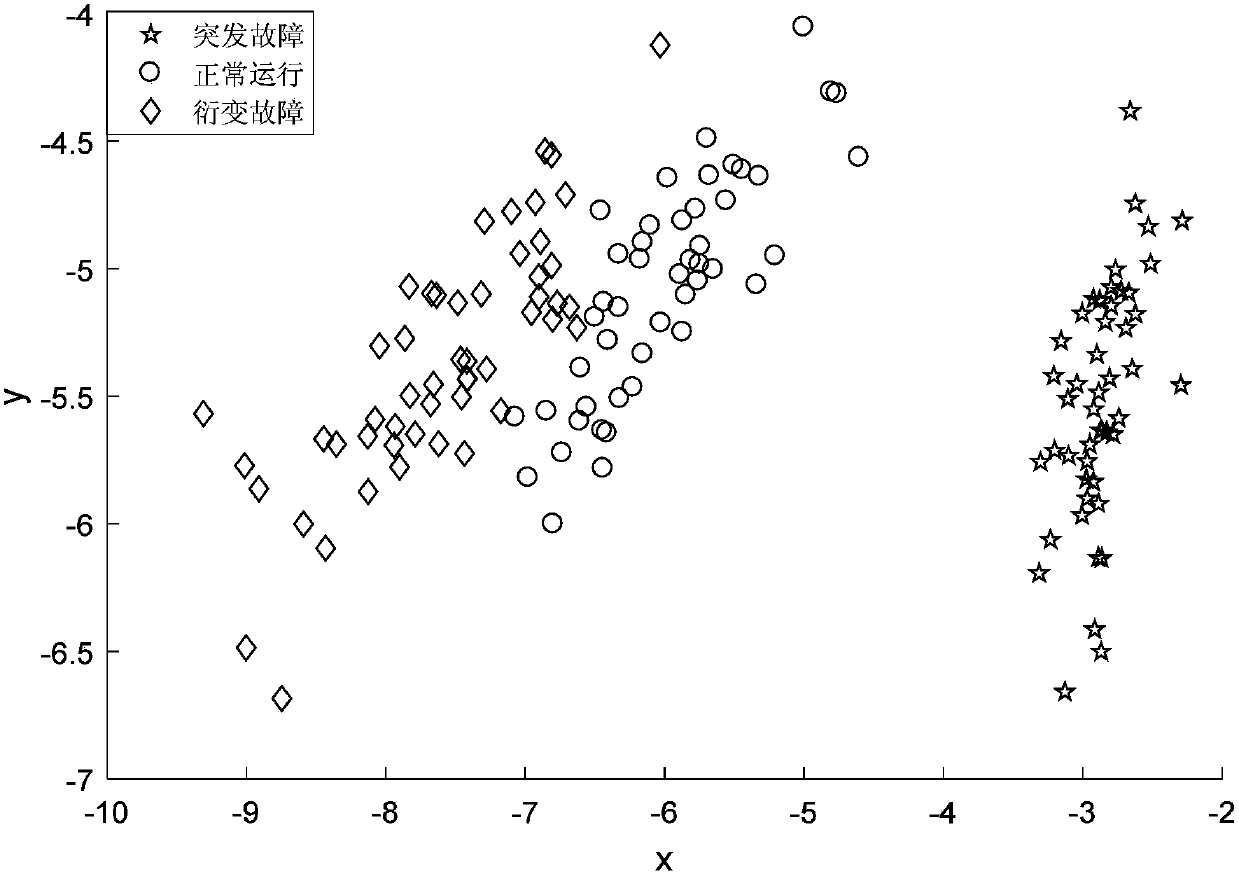

Examples

Embodiment Construction

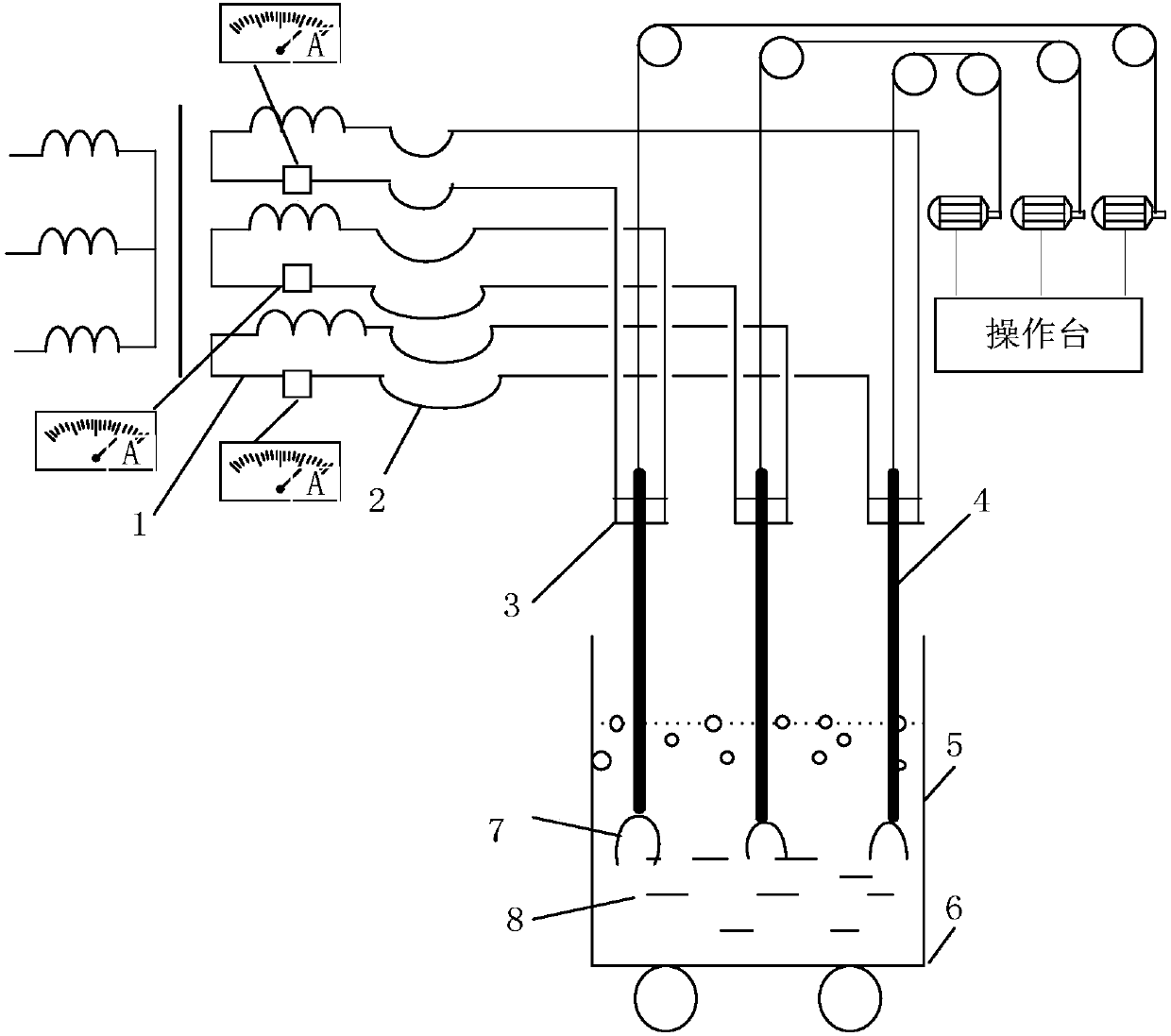

[0086] The specific implementation of the present invention will be further described in detail below with reference to the accompanying drawings and taking an electric fused magnesium furnace as an example. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0087] The fused magnesium furnace is actually a submerged arc furnace, which belongs to the submerged arc furnace rather than the electric arc furnace. It mainly uses the resistance heat of the material generated by the current passing through the material in the molten state as the main heat source, accompanied by arc heat, and its heat Concentration can effectively heat the material to a melting point above 2800°C, which is beneficial to smelting fused magnesia. The production process of fused magnesium furnace is as follows: figure 1 shown. The equipment of the fused magnesium furnace mainly includes: transformer, short circuit, ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com