Soil-free automatic vegetable greenhouse

A vegetable shed, automatic technology, applied in soilless cultivation, botanical equipment and methods, closed-circuit television systems, etc., can solve the problems of inability to reduce labor costs, promotion restrictions, etc., to achieve high production efficiency, less labor cost input, speed up The effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

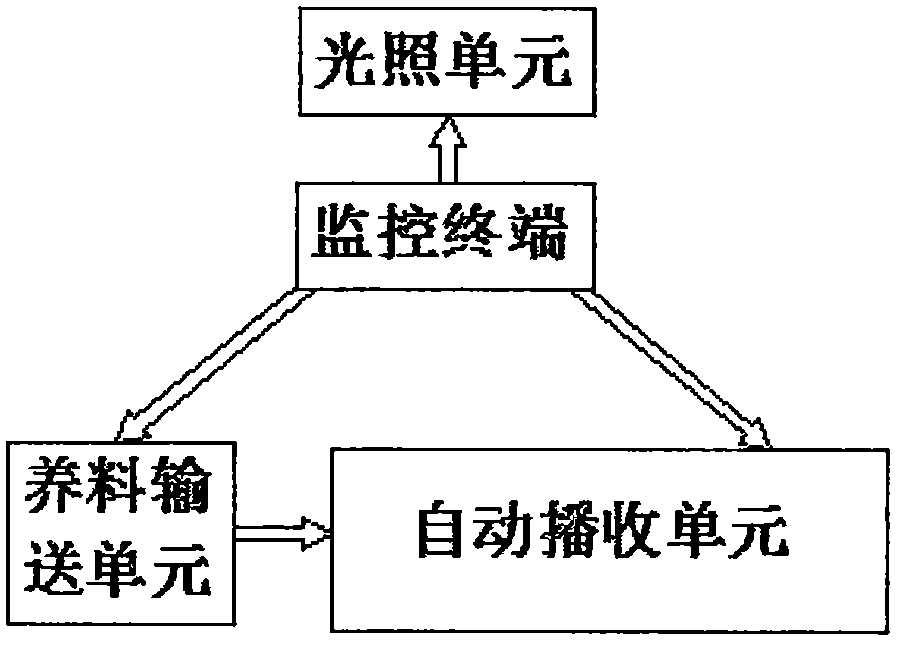

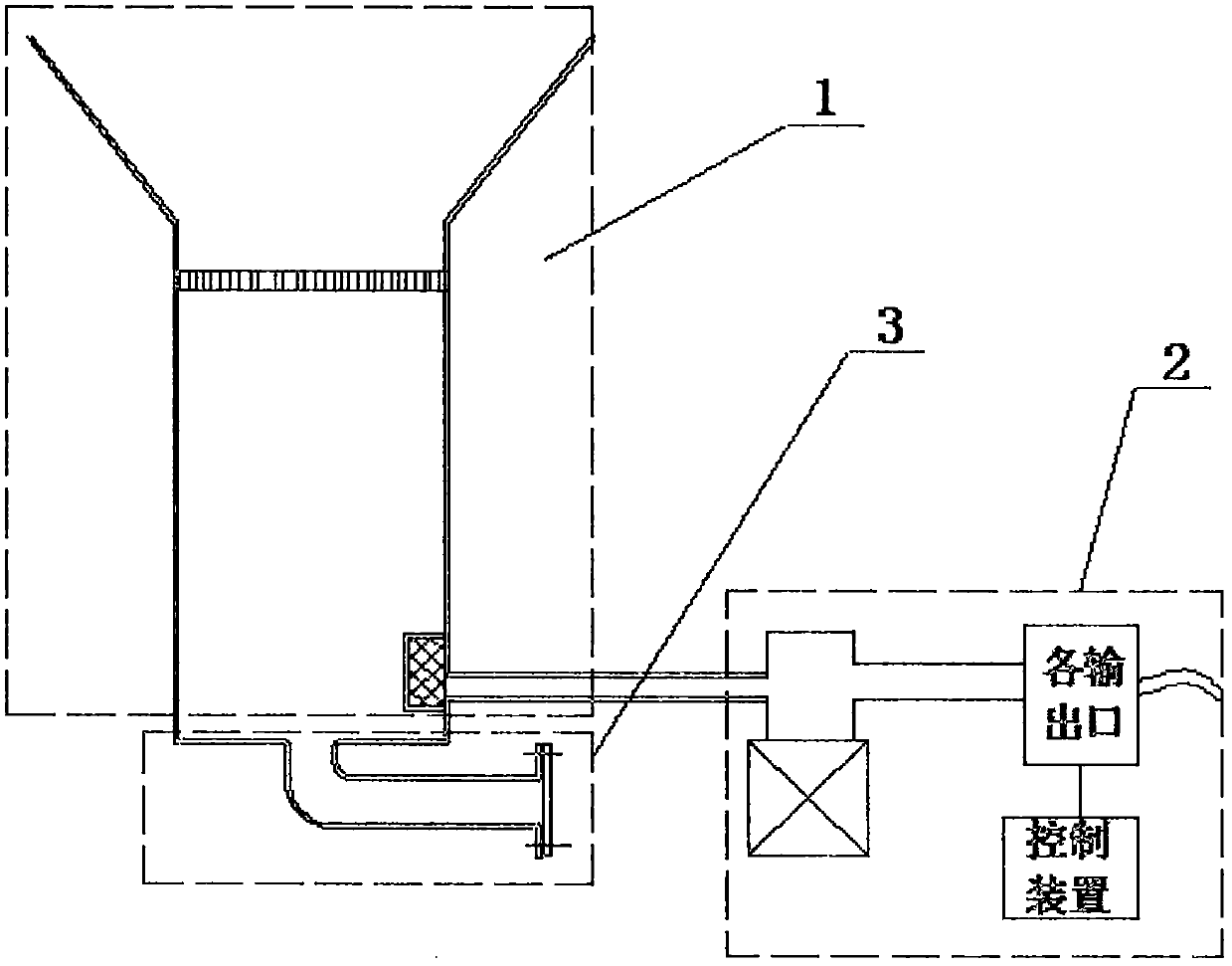

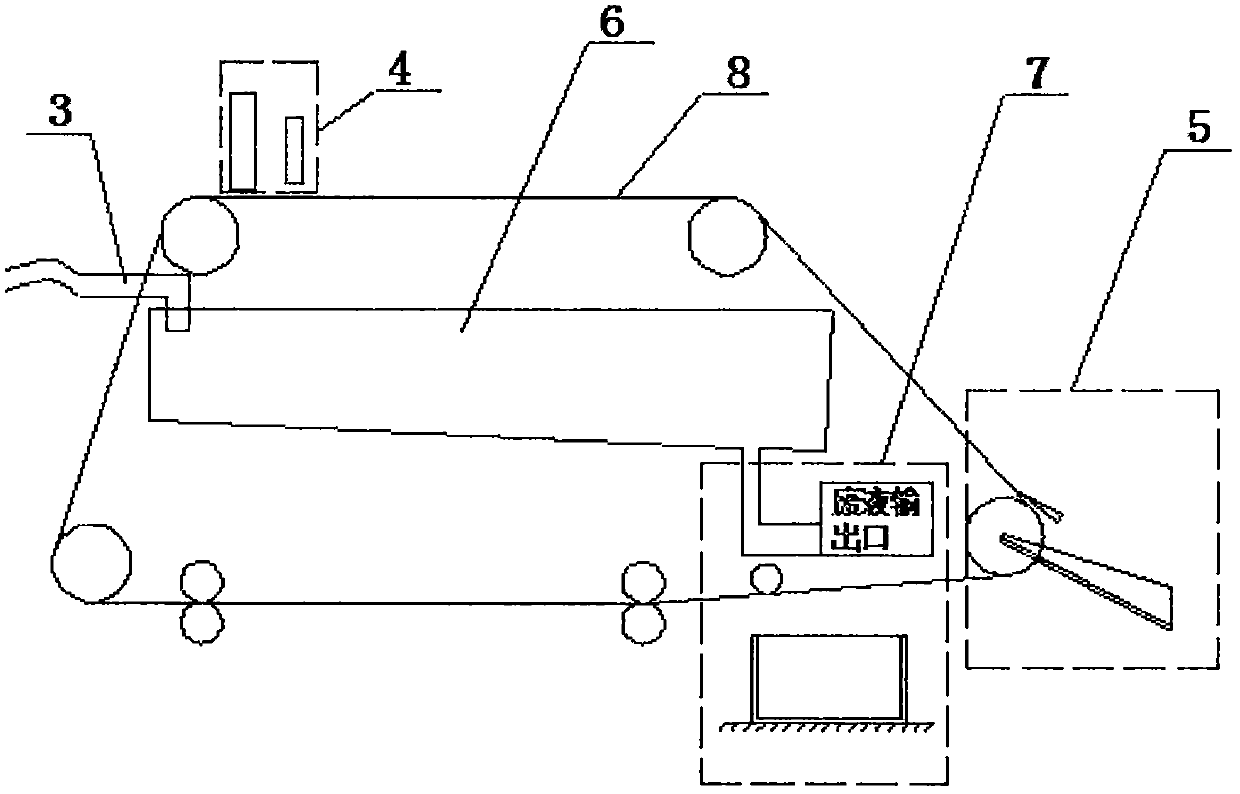

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, a soilless automated vegetable shed includes a monitoring terminal, the main body of the monitoring terminal is composed of a camera monitoring platform, and the monitoring terminal is connected with a lighting unit, a nutrient delivery unit and several automatic broadcasting units, The main body of the nutrient delivery unit is composed of a feed storage unit 1, a control delivery unit 2 and a sedimentation and slag discharge unit 3. The main body of the automatic sowing unit is composed of a seeding unit 4, a harvesting unit 5, a crop cultivation unit 6, residue The processing unit 7 and the rotating unit 8 are composed, the control conveying unit 2 is connected with the crop cultivating unit 6, the main body of the rotating unit 8 is composed of several sprockets and chains 9, and the chain 9 is provided with seedling raising box 10, the main body of the harvesting unit 5 is ...

Embodiment 2

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, a soilless automated vegetable shed includes a monitoring terminal, the main body of the monitoring terminal is composed of a camera monitoring platform, and the monitoring terminal is connected with a lighting unit, a nutrient delivery unit and several automatic broadcasting units, The main body of the nutrient delivery unit is composed of a feed storage unit 1, a control delivery unit 2 and a sedimentation and slag discharge unit 3. The main body of the automatic sowing unit is composed of a seeding unit 4, a harvesting unit 5, a crop cultivation unit 6, residue The processing unit 7 and the rotating unit 8 are composed, the control conveying unit 2 is connected with the crop cultivating unit 6, the main body of the rotating unit 8 is composed of several sprockets and chains 9, and the chain 9 is provided with seedling raising box 10, the main body of the harvesting unit 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com