Sand, gravel and pulp-water separating recycling and temperature control system

A temperature control system, separation and recovery technology, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve problems such as low efficiency, no supporting slurry water use plan, and inability to control slurry water temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

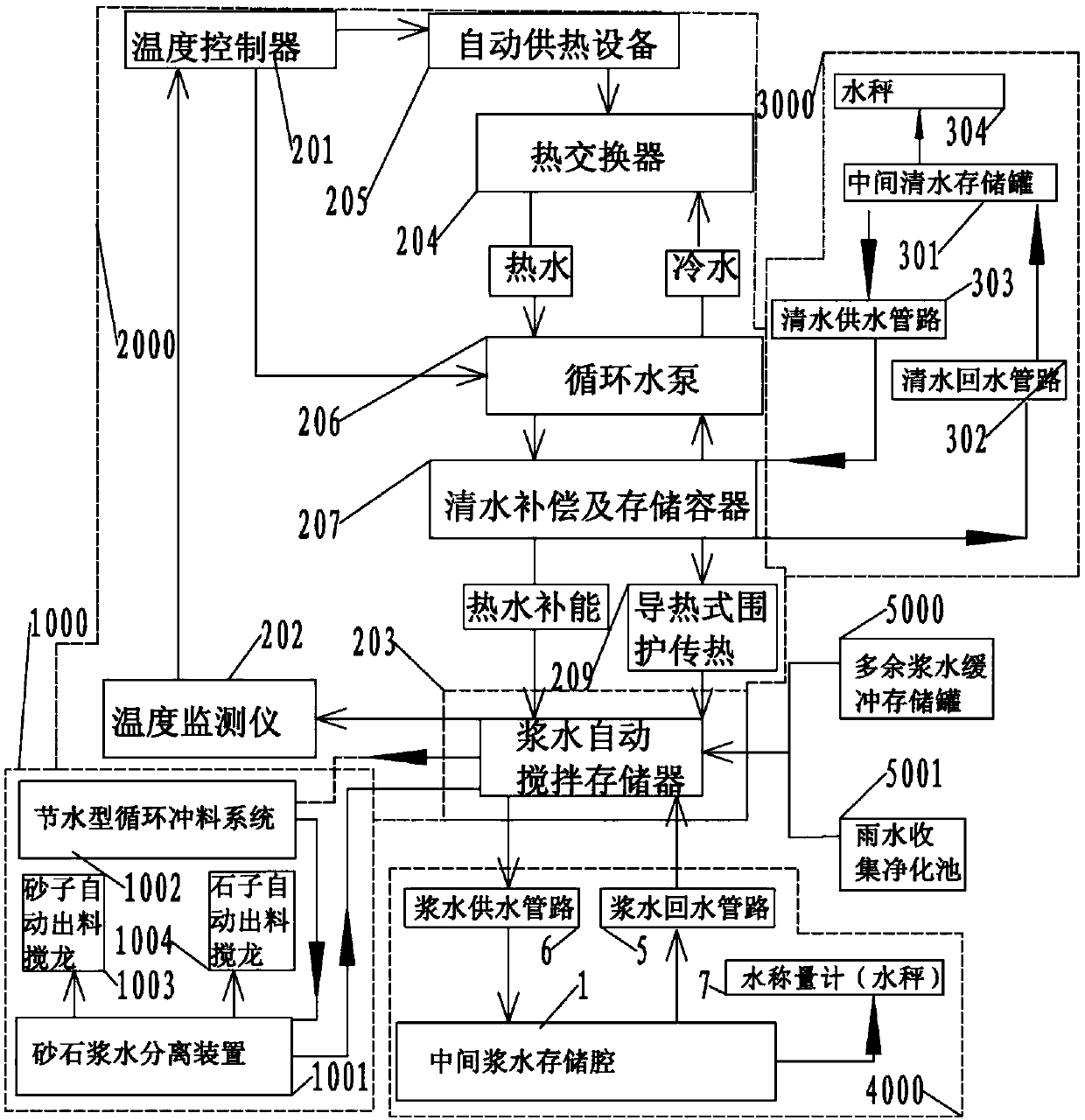

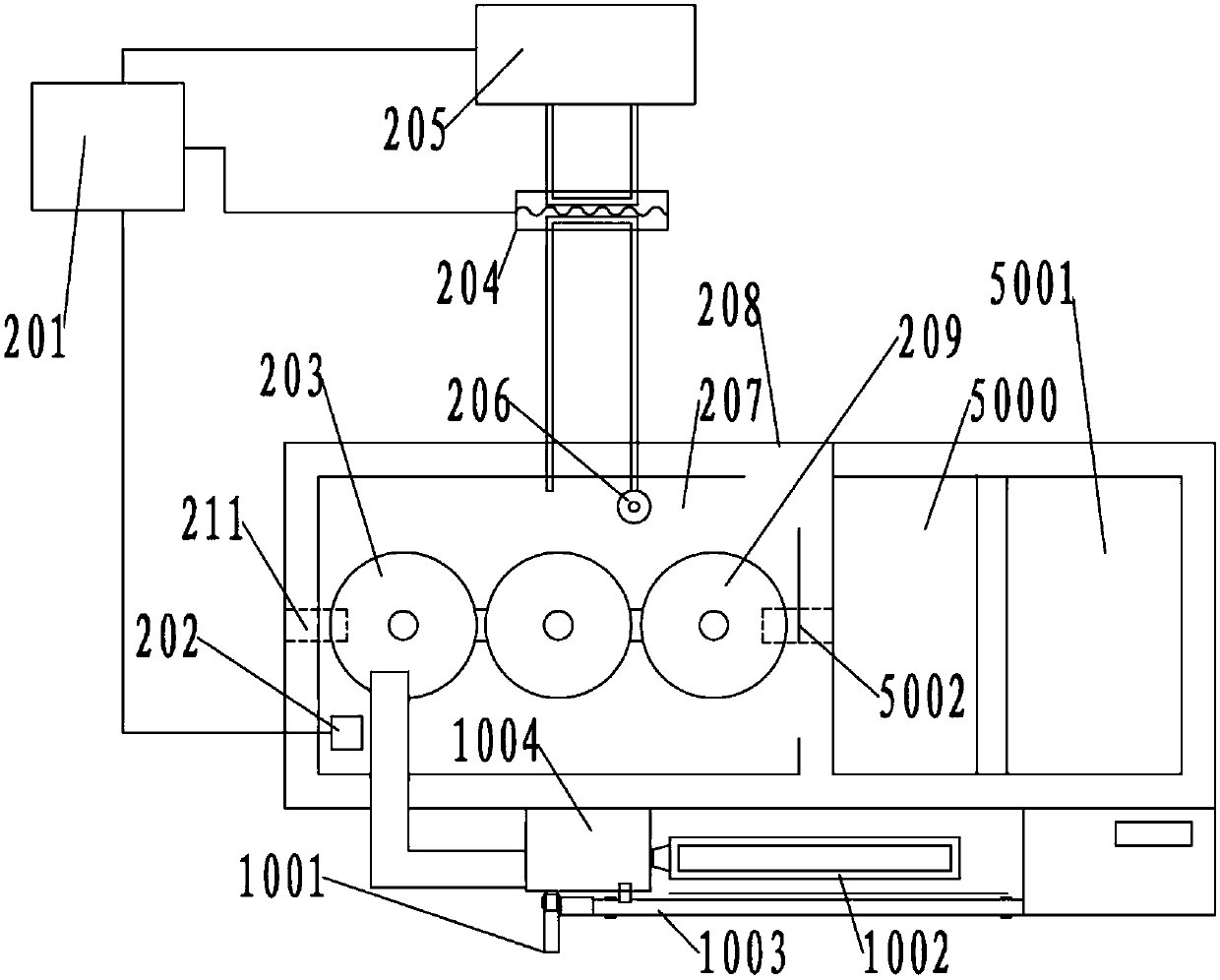

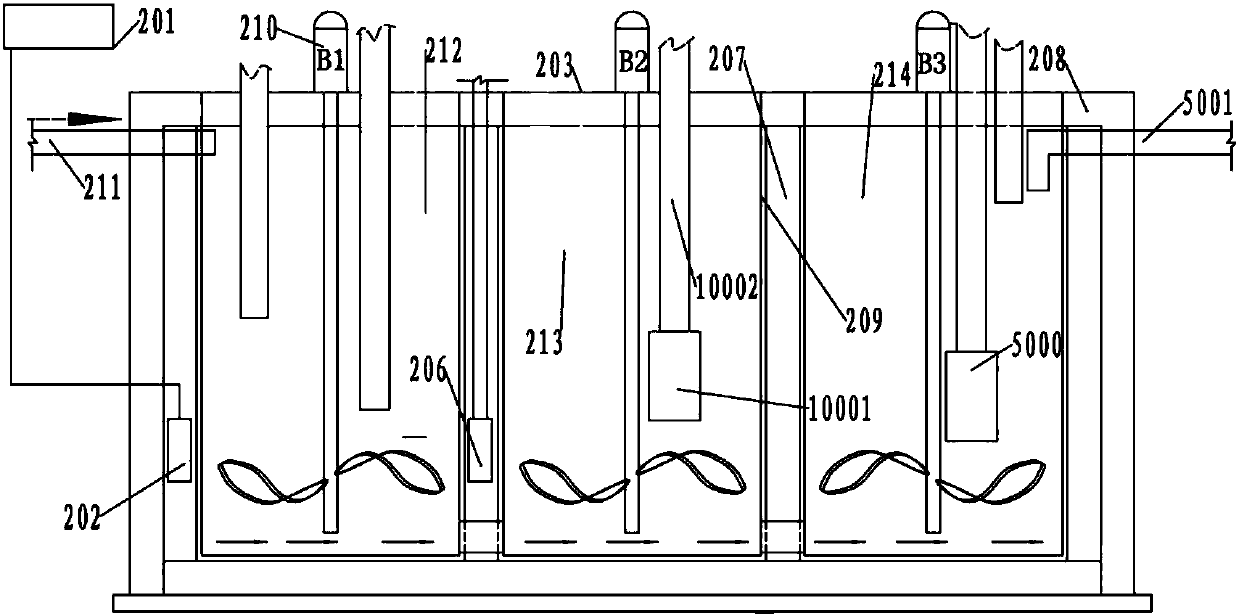

[0054] Such as Figure 1-7 As shown, the sandstone slurry water separation, recovery, reuse and temperature control system of this embodiment includes a slurry water automatic stirring storage 203 for storing slurry water in the container, and a sandstone slurry water separation system for separating sand, stones and slurry water. System 1000, the temperature control system 2000 set up with the slurry water heat exchange in the slurry water automatic stirring storage 203, the clear water replenishment system 3000 used to supply the temperature control system 2000 with clean water for heat exchange, and the automatic slurry water supply through the pipeline. The linkage type stabilized water supply device 4000 in the slurry water recovery and reuse system connected to the stirring storage 203;

[0055] The slurry water separated by the sandstone slurry water separation system 1000 communicates with the inlet of the slurry water automatic stirring storage 203 container through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com