Material pushing and detecting device of slag discharging machine

A technology of detection device and slag extractor, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of time-consuming and laborious, difficult slag tapping, difficult replacement and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

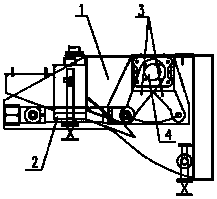

[0010] The present invention will be further explained below in conjunction with the accompanying drawings.

[0011] A material pushing detection device for a slag extractor, characterized in that: a slag extractor, a drive unit, a slag discharge tank, and a detection unit, the drive unit is connected to the crank.

[0012] To further illustrate, the slag outlet of the slagging tank is connected to the pre-concentration tank through a slagging pipe.

[0013] To further illustrate, the drive unit has built-in displacement sensors.

[0014] To further illustrate, the wear limit detection head in the detection unit is mounted on a sleeve protruding radially from the cutter head.

[0015] According to the principle of simplicity and ease of use, the invention has the advantages of convenient manufacture, reasonable use method, simple and easy structure, convenient operation, prevention of slag accumulation, energy saving, environmental protection, economy and durability, practica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com