Full-automatic fragrance agent production line

A freshener and production line technology, applied in the types of packaging items, special packaging items, labels, etc., can solve the problems of difficult recruitment, reduced profits, and increased labor costs for production enterprises, and achieve low production costs, high production efficiency, and reduced labor costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with specific embodiment:

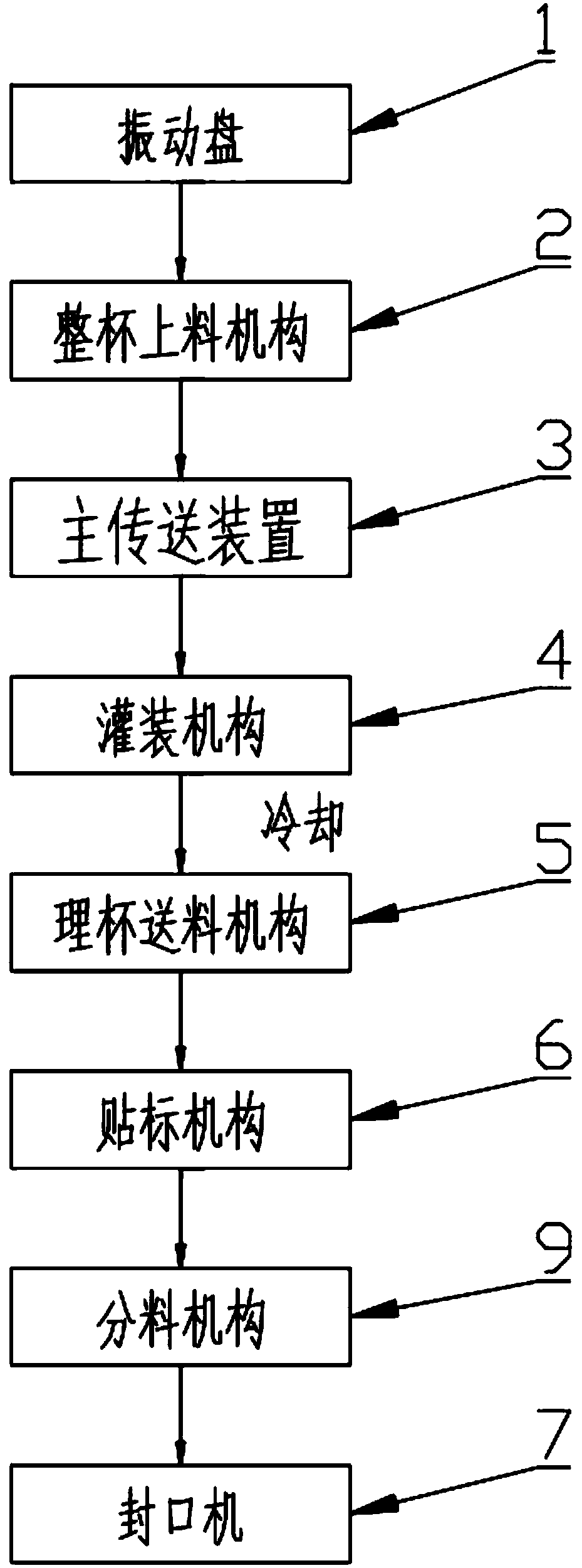

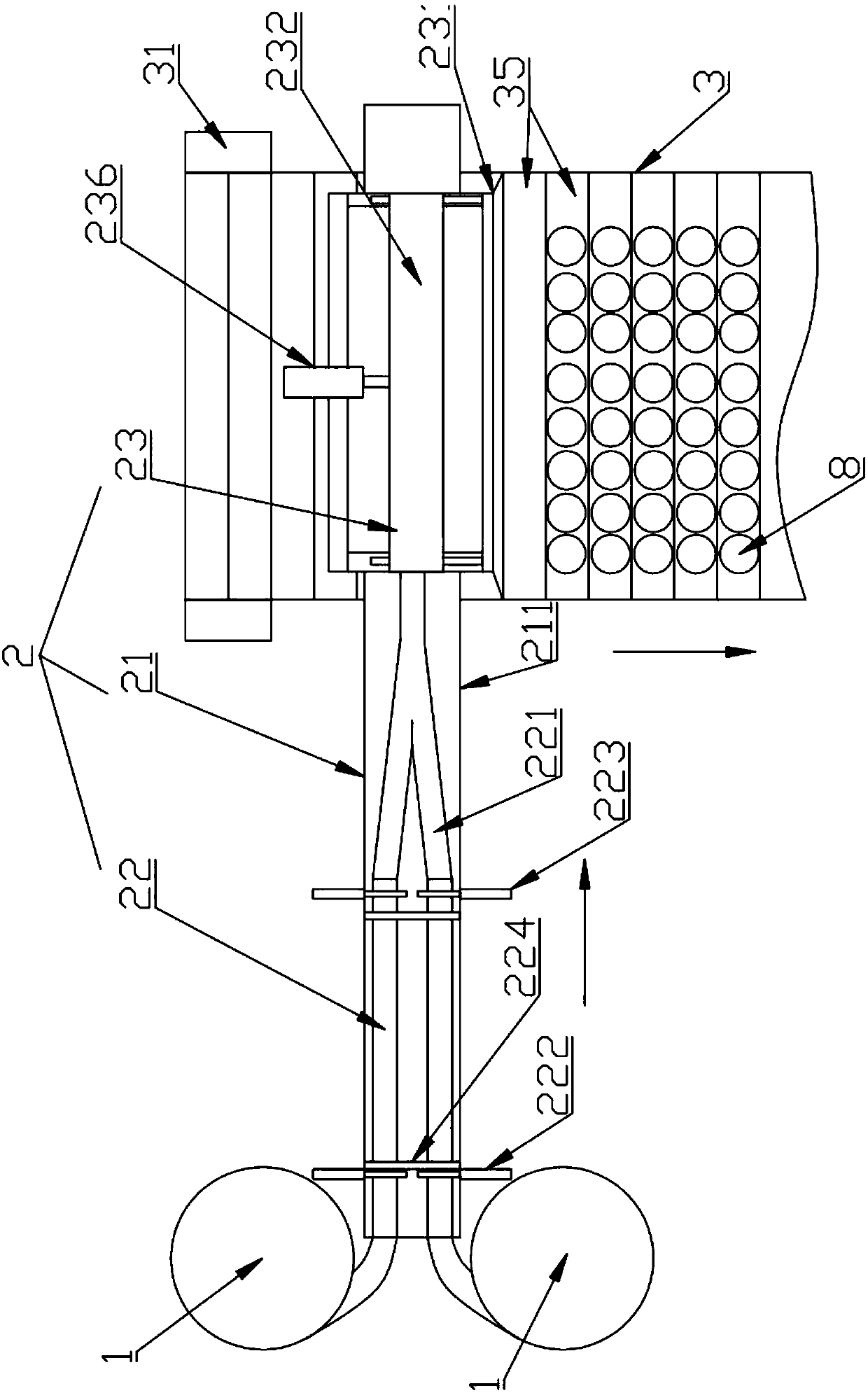

[0062] Such as figure 1 As shown: a fully automatic freshener production line, which sequentially includes a vibrating plate 1 for arranging packaging cups 8, a whole cup feeding mechanism 2 for transporting a specified number of packaging cups 8, a main conveying device 3 for transporting packaging cups 8, Filling mechanism 4 for pouring fresh fragrance, cup sorting and feeding mechanism 5 for sorting packaging cup 8, labeling mechanism 6 for labeling tape 65 for packaging cup 8, and sealing for packaging cup 8 Machine 7;

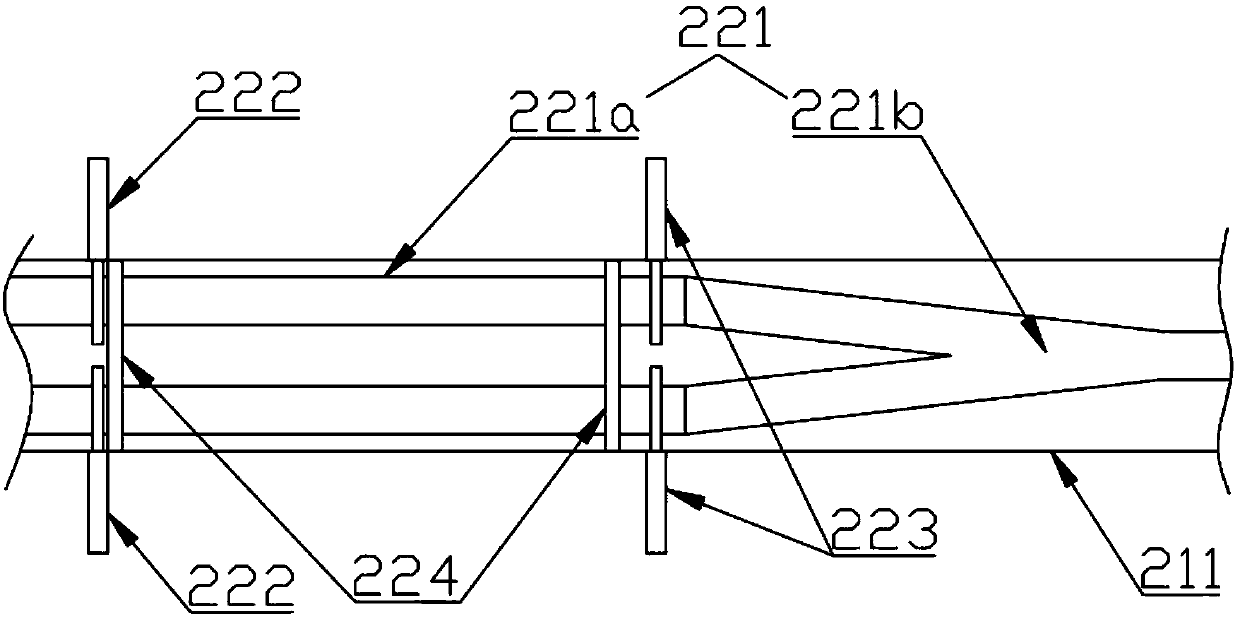

[0063] The vibrating plate 1 is connected to the whole cup feeding mechanism 2, and the whole cup feeding mechanism 2 can transport a specified number of packaging cups 8 to the installation groove 35 at the front end of the main conveying device 3, and the filling mechanism 4 is set At the front end of the main conveying device 3, the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com