Double screw lift

A lift and screw technology, applied in the field of lifts, can solve the problems of doubts about the transmission load, material falling and hurting people, wire rope breakage, etc., so as to reduce the difficulty of handling and the limitation of installation space, reduce the difficulty and cost of production, and avoid suffering. Effect of Radial Force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

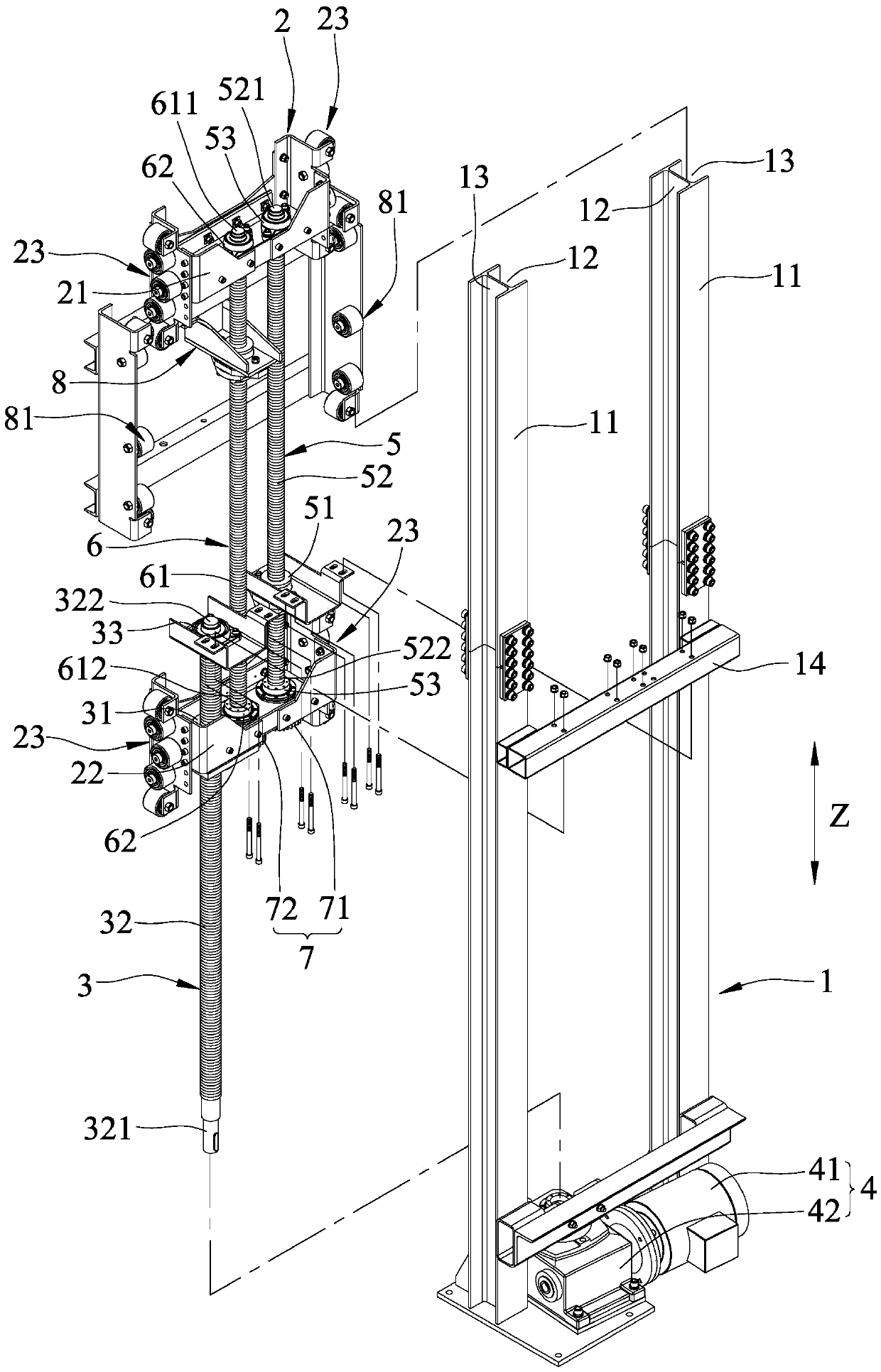

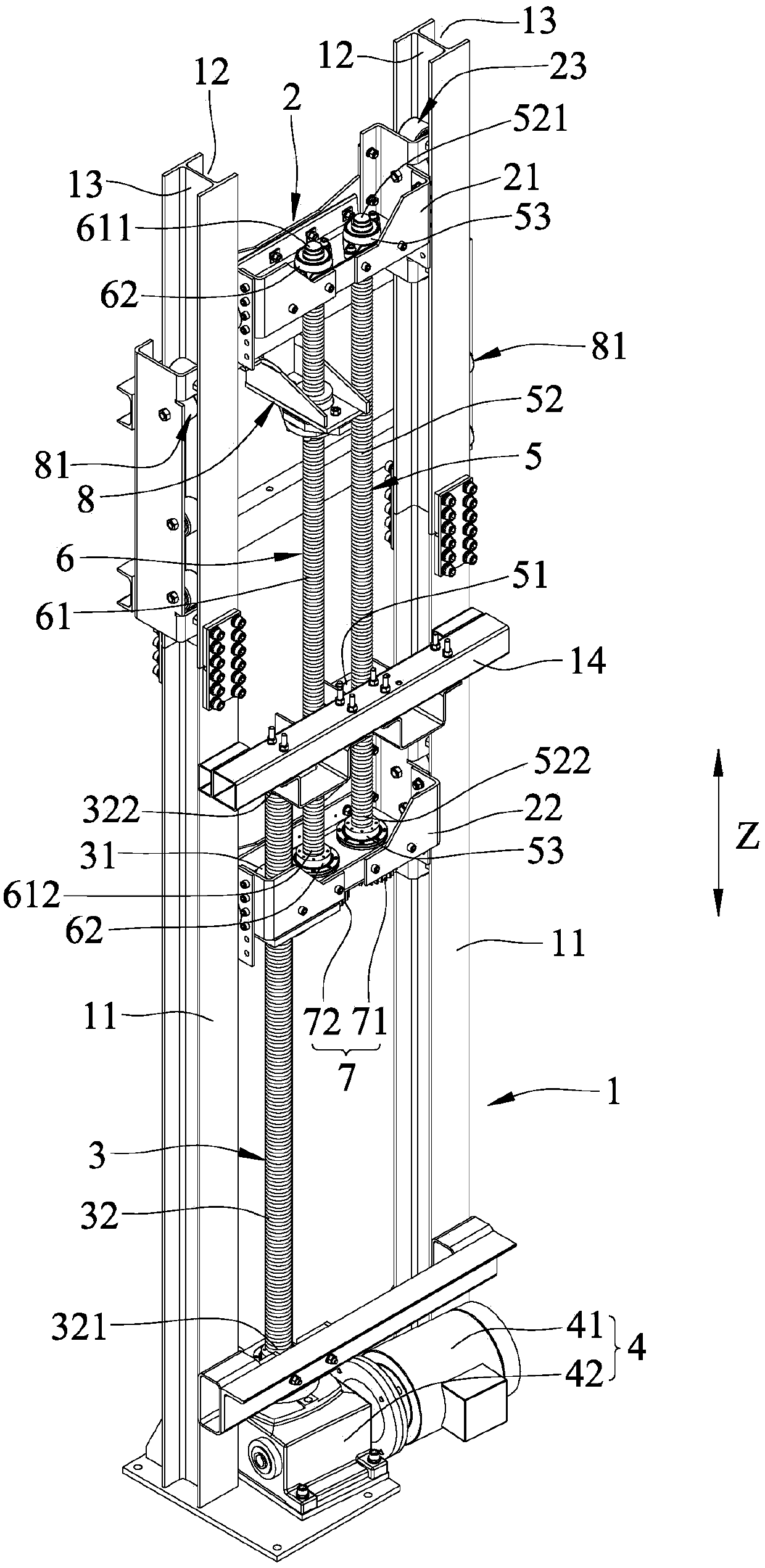

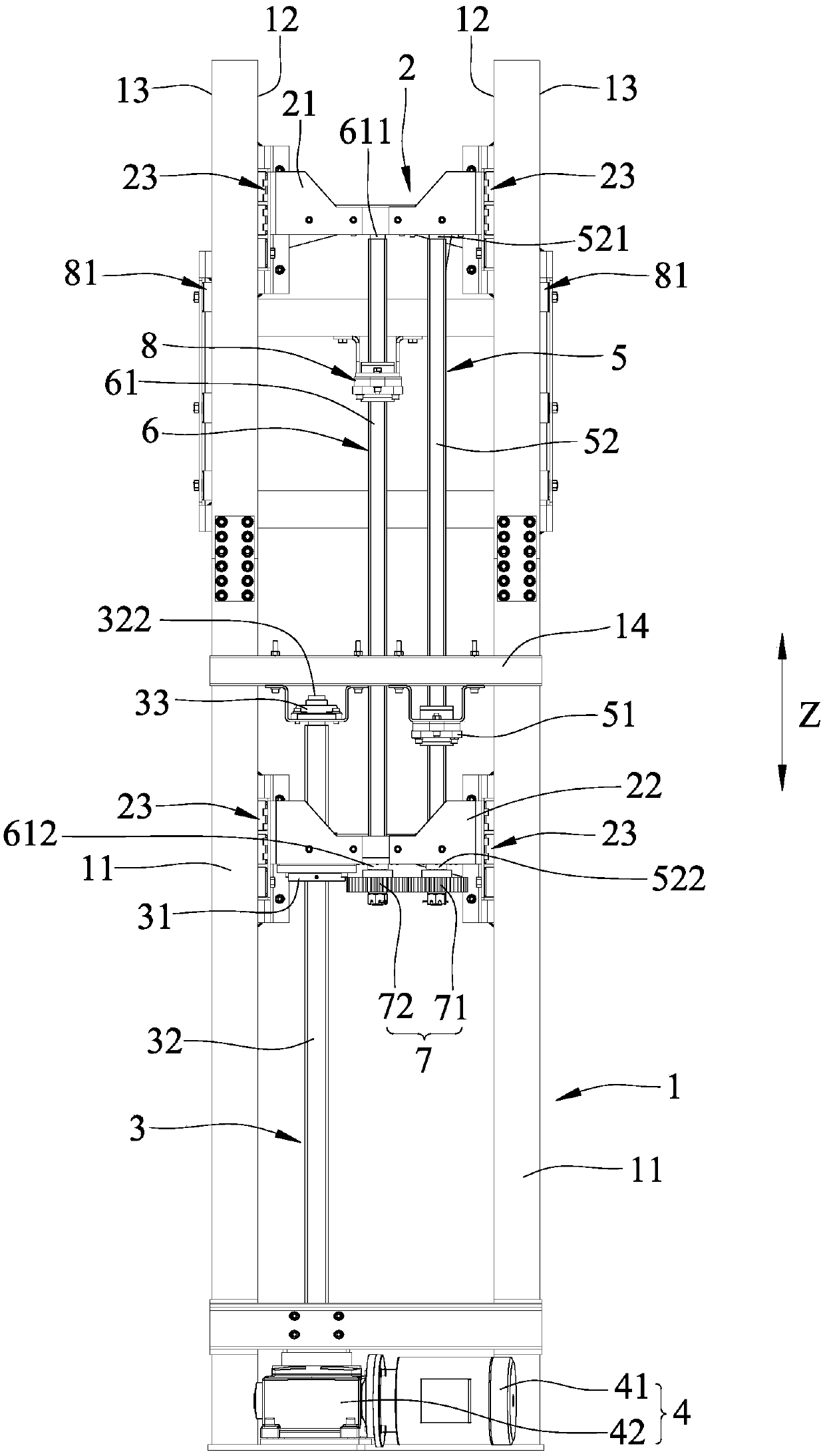

[0028] refer to figure 1 , figure 2 and image 3 , an embodiment of the screw double lift type elevator of the present invention comprises a track frame 1, a slide unit 2, a transmission screw group 3, a drive unit 4, a linkage screw group 5, a driven screw group 6. A transmission unit 7 and a load slide 8.

[0029] The track rack 1 includes two parallel and spaced apart supports 11 extending upright along an up-down direction Z, two inner rails 12 respectively arranged on opposite sides of the supports 11, two inner rails 12 respectively arranged on the opposite sides of the supports 11, The outer rail 13 at the opposite side of the support member 11, and a fixing member 14 connected to the middle section of the support member 11. Each inner rail 12 and each outer rail 13 extend along the vertical direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com