A kind of polymer with surface activity for oil displacement and its preparation method and application

A technology of surface activity and polymers, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems such as few reports, and achieve improved polymerization activity, excellent viscosity increase, temperature resistance and salt resistance, and emulsification performance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

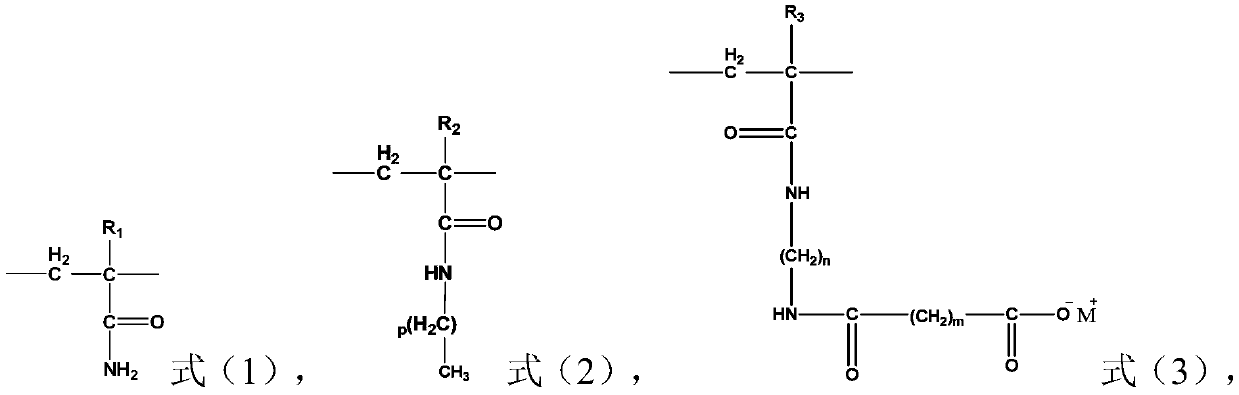

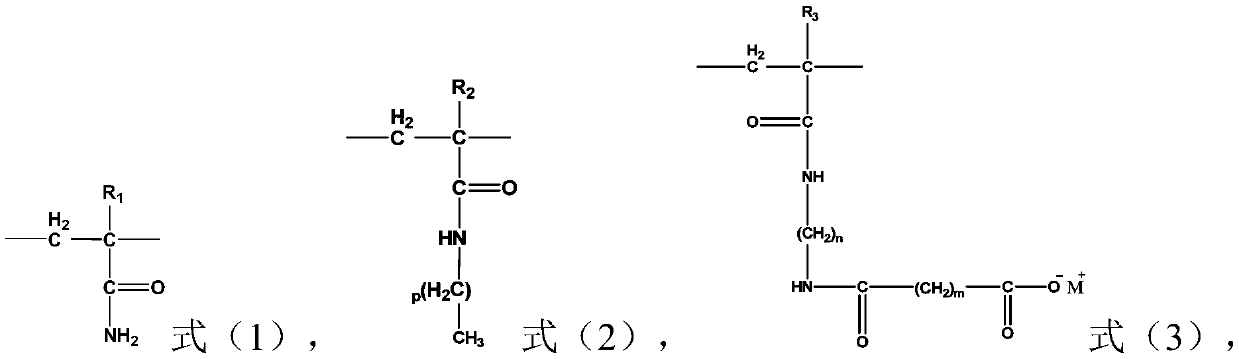

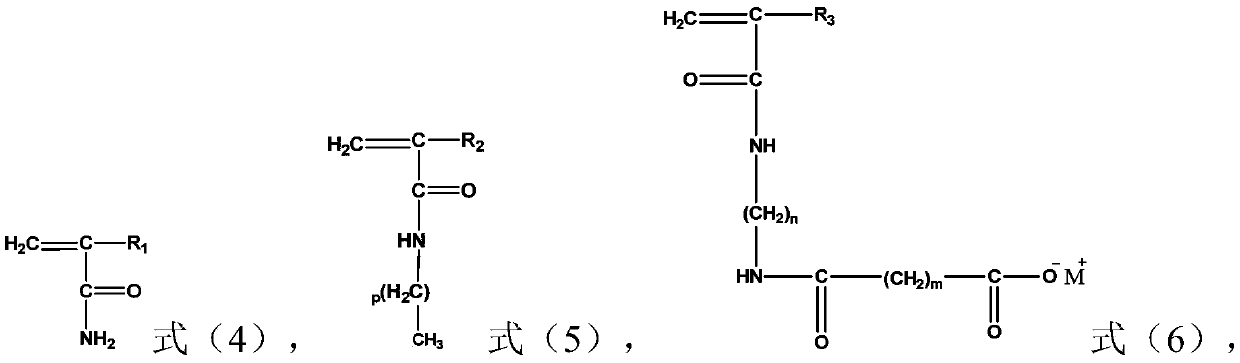

Method used

Image

Examples

specific Embodiment approach

[0069] According to a preferred embodiment, the preparation method of the polymer for oil displacement with surface activity comprises the following steps:

[0070] Step 1: adding monomer D and monomer F into a polymerization reaction bottle to prepare an aqueous solution, and adjusting the pH value of the aqueous solution to 6-10 with alkali;

[0071] Step 2: Add monomer E, chelating agent, emulsifier and accelerator to the aqueous solution in step 1, and stir evenly to make it a stable micellar solution;

[0072] Step 3: At a temperature of 0-30°C, after bubbling nitrogen for 5-60 minutes, add the initiator to the micellar solution in step 2, and after bubbling nitrogen to make it evenly mixed, seal polymerization for 2-15 hours to obtain polymer colloid;

[0073] Step 4: Take out the polymer colloid, add alkaline substances after granulation, mix well, and perform hydrolysis at 50-120°C for 0.5-8 hours;

[0074] Step 5: Take out the colloid and then granulate, dry, pulver...

Embodiment 1

[0084] Embodiment 1: Preparation has surface active polymer for oil displacement

[0085] 1. Mix 17.0g of acrylamide (accounting for 85% by weight of the total amount of monomers), 2.0g of the hydrophilic monomer represented by formula (12) (m=6, n=2, accounting for 10% of the total amount of monomers) % by weight) was added to the thermal insulation polymerization reaction bottle (ie, the polymerization bottle), and 60.0 g of deionized water was added to dissolve to form an aqueous solution, and then sodium hydroxide was added to adjust the pH to 6.0;

[0086] 2. Add the hydrophobic monomer (p=9, accounting for 5% by weight of the total amount of monomers) shown in 1.0g of formula (11), 0.2g of sodium lauryl sulfate, 1% by weight of EDTA- 1.0 g of 2Na aqueous solution, 0.5 g of 1% by weight aqueous urea solution, 20.0 mg of pentamethyldiethylenetriamine, and fully stirred to obtain stable micelles;

[0087] 3. Control the temperature of the aqueous solution at 10° C., and th...

Embodiment 2

[0091] Embodiment 2: Preparation has surface active polymer for oil displacement

[0092] 1. 17.98g of acrylamide (accounting for 89.9% by weight of the total amount of monomers), 2.0g of the hydrophilic monomer represented by formula (12) (m=4, n=6, accounting for 10% of the total amount of monomers) % by weight) was added to the thermal insulation polymerization reaction bottle (ie, the polymerization bottle), and 60.0 g of deionized water was added to dissolve to form an aqueous solution, and then sodium hydroxide was added to adjust the pH to 7.0;

[0093] 2. Add the hydrophobic monomer shown in 0.02g of formula (11) (p=13, accounting for 0.1% by weight of the total amount of monomers), 0.1g of sodium lauryl sulfate, 1% by weight of EDTA- 1.0 g of 2Na aqueous solution, 0.5 g of 1% by weight aqueous urea solution, 40.0 mg of pentamethyldiethylenetriamine, and fully stirred to obtain stable micelles;

[0094] 3. Control the temperature of the aqueous solution at 5° C., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com