Sulfamate water reducing agent and preparation method thereof

A technology of sulfamate and p-aminobenzenesulfonic acid, which is applied in the field of concrete admixtures, can solve problems such as increasing the complexity of manufacturing, and achieve the effects of improving adaptability, easy mixing, and reducing sensitivity of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

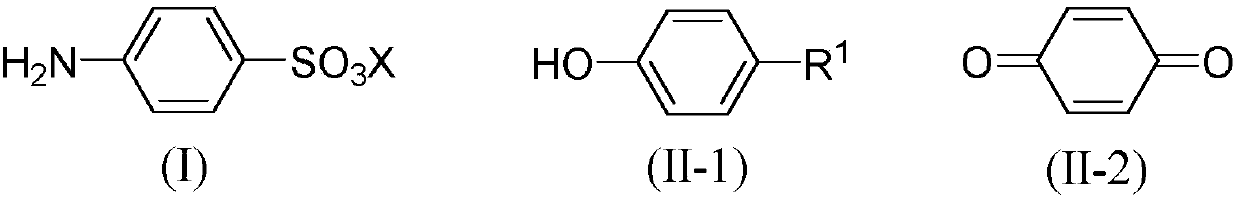

Method used

Image

Examples

Embodiment 1

[0067] A kind of sulfamate water reducer, its preparation steps are as follows:

[0068] (1) Add 236kg of sodium p-aminobenzenesulfonate dihydrate (98%) and 190kg of phenol (98%) into 500kg of water in sequence, and heat the mixing system to 75°C, stir, dissolve and mix;

[0069] (2) adding sodium hydroxide solution (30%) to adjust the pH value to 9.5;

[0070] (3) Slowly add 284kg of formaldehyde solution (37%) so that the temperature of the reaction solution does not exceed 95°C, and then keep the temperature at 94 to 96°C for 5 hours;

[0071] (4) Cool down to 60-70° C., add 22 kg of hydrogen peroxide (30%), keep warm within this temperature range for 1 hour, and cool to obtain a liquid product.

Embodiment 2

[0073] A kind of sulfamate water reducer, its preparation steps are as follows:

[0074] (1) Add 236kg of sodium p-aminobenzenesulfonate dihydrate (98%) and 152kg of phenol (98%) into 600kg of water in sequence, and heat up the mixing system to 75°C, stir, dissolve and mix;

[0075] (2) adding sodium hydroxide solution (30%) to adjust the pH value to 9.4;

[0076] (3) Slowly add 243kg of formaldehyde solution (37%) so that the temperature of the reaction solution does not exceed 95°C, and then keep the temperature at 92 to 94°C for 5.5 hours;

[0077] (4) Cool down to 60-70° C., add 11 kg of hydrogen peroxide (30%), keep warm within this temperature range for 1 hour, and cool to obtain a liquid product.

Embodiment 3

[0079] A kind of sulfamate water reducer, its preparation steps are as follows:

[0080] (1) Add 236kg of sodium p-aminobenzenesulfonate dihydrate (98%) and 171kg of phenol (98%) into 600kg of water in turn, and heat up the mixing system to 75°C, stir, dissolve and mix;

[0081] (2) adding sodium hydroxide solution (30%) to adjust the pH value to 9.7;

[0082] (3) Slowly add 308kg of formaldehyde solution (37%) so that the temperature of the reaction solution does not exceed 95°C, and then keep the temperature at 95 to 97°C for 4.5 hours;

[0083] (4) Cool down to 60-70° C., add 42 kg of potassium permanganate (99.5%), keep warm within this temperature range for 1 hour, and cool to obtain a liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com