A kind of preparation method of nano-eutectic crystal reinforced mg-zn-y alloy

A mg-zn-y, alloy technology, applied in the field of magnesium alloy manufacturing, can solve problems such as less research and achieve significant benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

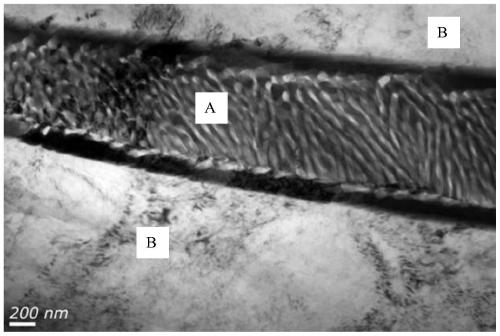

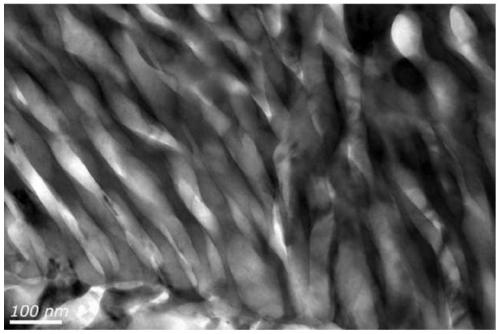

Image

Examples

Embodiment 1

[0030] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0031] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 3% Zn, 0.5% Y , and the rest are Mg;

[0032] B, the as-cast Mg-Zn-Y alloy prepared in step A is annealed at 400 DEG C for 12h, and cooled with the furnace;

[0033] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 320° C. for 4 hours, hot extrusion is carried out, the extrusion temperature is 320° C., and the extrusion ratio is 20:1;

[0034] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 560° C. with the furnace, keep it warm for 10 minutes, and then quench it with water at 60° C. Quasicrystalline reinforced Mg-Zn-Y alloys.

[0035] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A described in this exampl...

Embodiment 2

[0039] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0040] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 1.5% Zn, 0.25% Y , and the rest are Mg;

[0041] B. Anneal the as-cast Mg-Zn-Y alloy prepared in step A at 400° C. for 12 hours, and cool with the furnace.

[0042] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 320°C for 4h, hot extrusion is carried out, the extrusion temperature is 320°C, and the extrusion ratio is 20:1;

[0043] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 580° C. with the furnace, keep it warm for 10 minutes, and then quench it with water at 60° C. to obtain nano-copolymer Quasicrystalline reinforced Mg-Zn-Y alloys.

[0044] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A described...

Embodiment 3

[0047] A preparation method of nano-eutectic crystal reinforced Mg-Zn-Y alloy, the steps are as follows:

[0048] A. Prepare the cast Mg-Zn-Y alloy according to the set atomic percentage ratio of each constituent element; the set atomic percentages of each constituent element are: 0.5% Zn, 0.08% Y , and the rest are Mg;

[0049] B, the as-cast Mg-Zn-Y alloy prepared by step A is annealed at 380 ℃ for 20h, and cooled with the furnace;

[0050] C. After the annealed Mg-Zn-Y alloy obtained in step B is kept at 300° C. for 4 hours, hot extrusion is carried out, the extrusion temperature is 300° C., and the extrusion ratio is 9:1;

[0051] D. Place the hot-extruded Mg-Zn-Y alloy obtained in step C in a heat treatment furnace, heat up to 550° C. with the furnace, keep it warm for 20 minutes, and then quench it with water at 30° C. to obtain nano-copolymer Quasicrystalline reinforced Mg-Zn-Y alloys.

[0052] The specific operation of preparing the as-cast Mg-Zn-Y alloy in step A d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com