Detergent Dosing Controller

A detergent injection and controller technology, which is applied to washing machine control devices, washing devices, other washing machines, etc., can solve problems such as insufficient detergent inventory, complex structure of detergent injection devices, etc., and achieve reasonable detection and judgment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

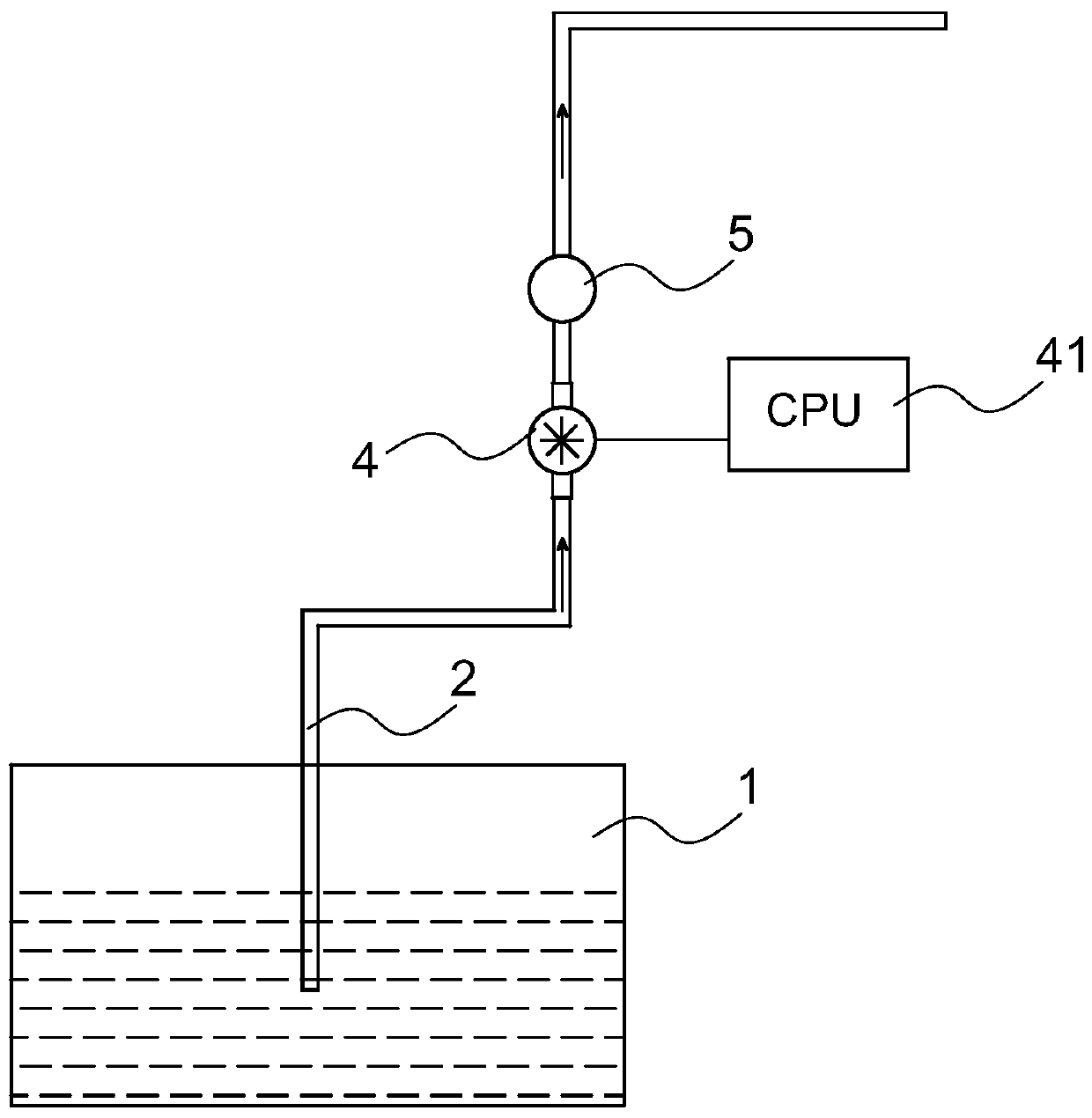

[0023] The detergent injection controller is provided with a detergent storage box 1 and an infusion channel 2 with inner and outer ends open, the inner port of the infusion channel is connected to the detergent storage box 1, and the infusion channel 2 is sequentially set Flow sensor 4 and extracting device 5 are arranged, and flow sensor 4 is connected with microprocessor CPU 41, and this microprocessor is provided with this program: after opening the extracting device 5 to extract the detergent in the detergent storage box 1, record every The number of pulse signals Pn of the flow sensor within 0.2 seconds, and then compare the number of pulse signals recorded at the current time with the number of pulse signals recorded at the previous time. If the number of pulse signals increases, it is determined that the washing in the detergent storage box is If the detergent is insufficient, then the alarm prompts the user to add detergent.

[0024] The present invention works in ext...

Embodiment 2

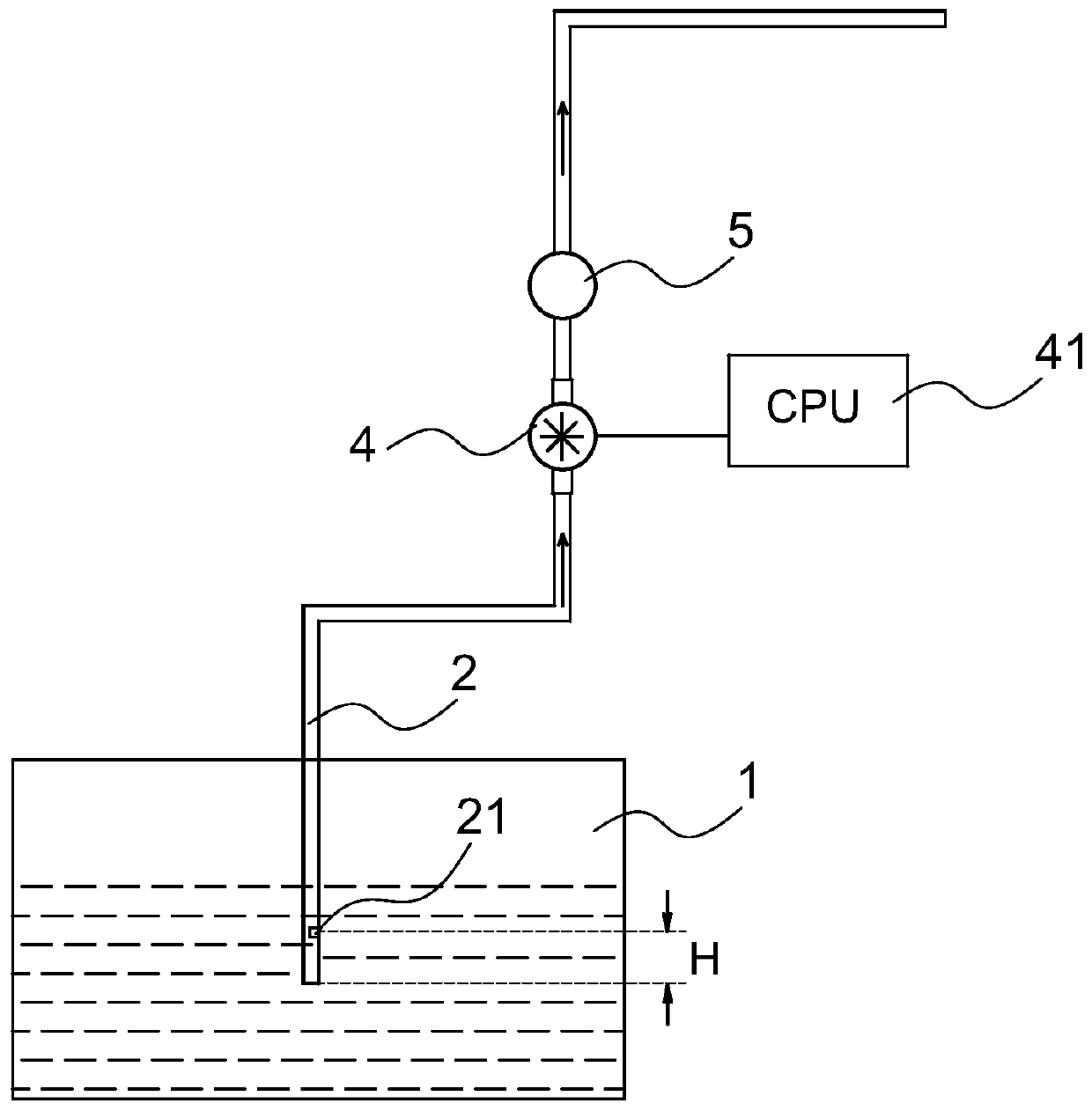

[0026] This example is different from the previous example in that a section of the infusion channel located in the detergent storage box is provided with a port 21, and the horizontal position of the port is higher than the horizontal position of the port in the infusion channel by a distance H, see figure 2 , the diameter of the port 21 is smaller than that of the inner port of the infusion channel 2 . When the detergent is extracted and the liquid level of the detergent is lower than the port 21, the air is sucked into the infusion channel. Since the aperture of the port 21 is smaller than the diameter of the inner port of the infusion channel 2, the detergent is also sucked in while the air is sucked, and the air and the washing Because the flow resistance of the detergent mixture is smaller than that of pure detergent, the flow rate of the mixture is greater than that of pure detergent. Compared with pure detergent, the number of pulse signals output by the flow sensor pe...

Embodiment 3

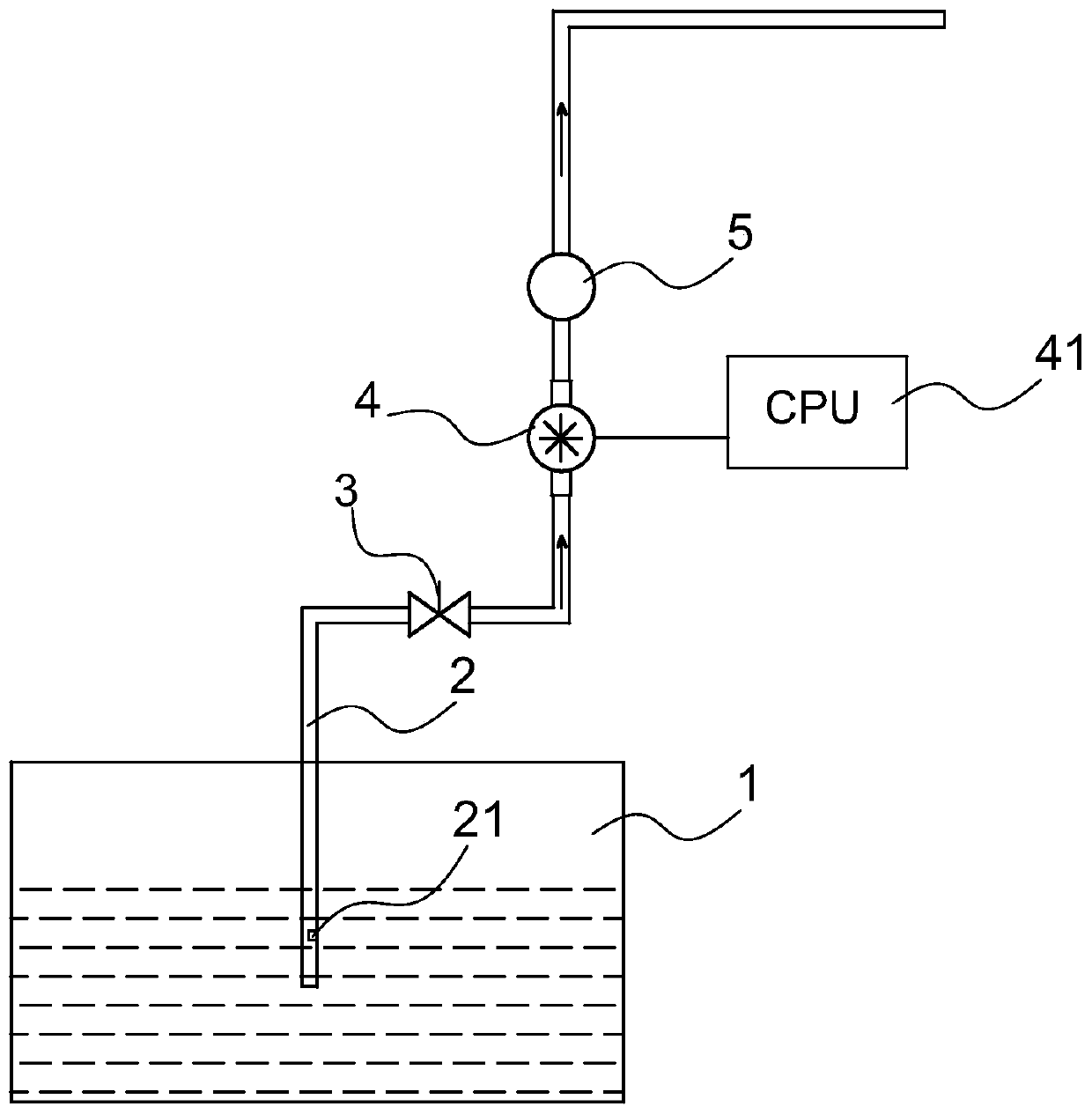

[0028] This example is different from Example 2 in that a valve A3 is provided between the flow sensor 4 and the washing liquid storage tank 1 on the infusion channel 2, see image 3 . Other structures are the same as in Example 2. Figure 5 "Valve A open" in the program principle shown corresponds to this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com