Arched and cable-stayed combination type system bridge and construction method thereof

A construction method and system technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable load effects on arch feet, substructures and foundations, unsatisfactory technical solutions, and difficult construction techniques, etc., to achieve the elimination of unfavorable influence, reduce the difficulty of design and construction, and reduce the effect of section size and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

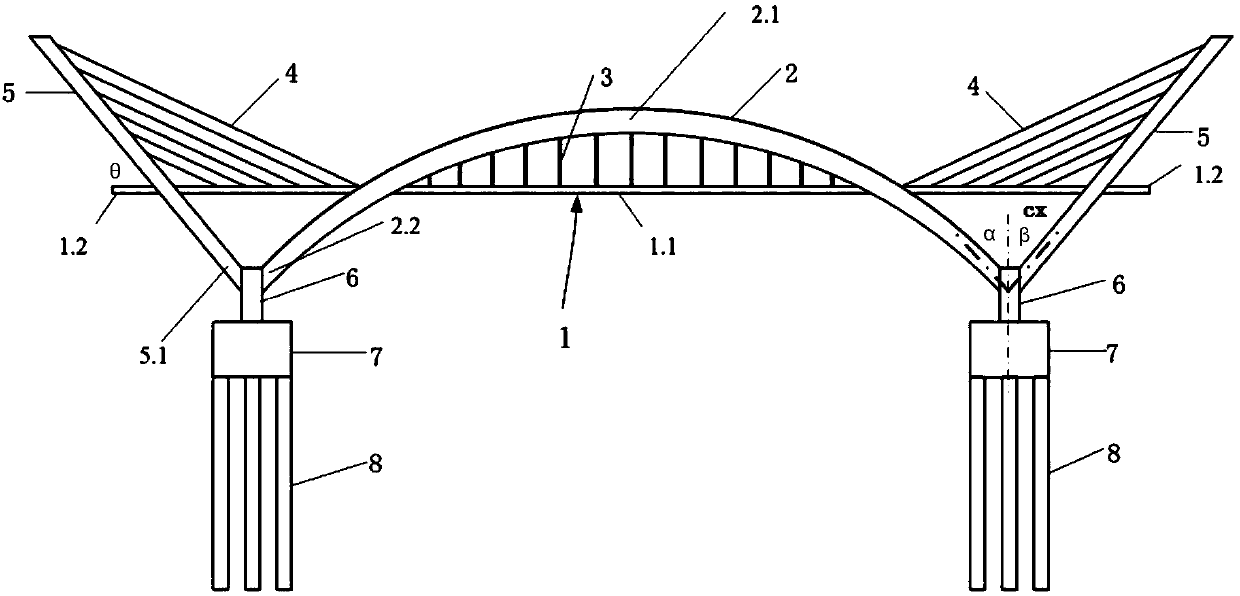

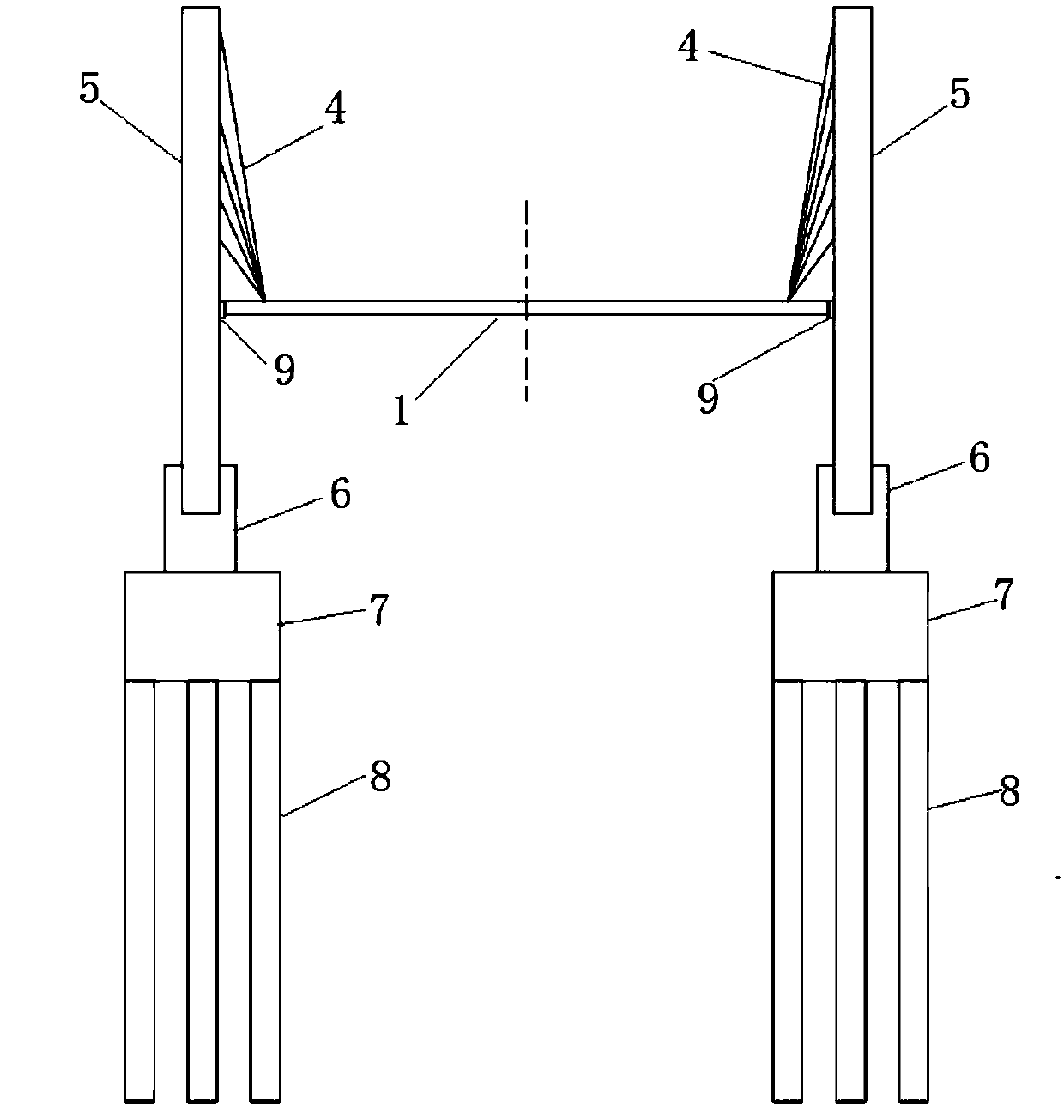

[0041] A bridge with arch and cable-stayed composite system, such as figure 1 , figure 2 and image 3 As shown, it is a three-span structure, including two side spans and a middle span. The middle span is supported by a mid-span arch rib 2. And the stay cable anchor tower column 5 becomes the load-bearing structure of the whole bridge. The section of the bridge deck 1 between the two sections of the arch rib is the middle span 1.1, and the road surface beyond the two ends of the arch rib is the side span 1.2. A suspender 3 is arranged between the passage surface of the bridge deck and a part of the arch ribs above the passage surface, and the bridge deck is fixed on the arch rib 2 through the suspender 3 .

[0042] It is worth noting that the two arch ribs can be provided with transverse connecting members in the transverse direction, or the two arch ribs can adopt separate arch ribs or basket-type arch ribs. The arch rib adopts structural forms such as reinforced concret...

Embodiment 2

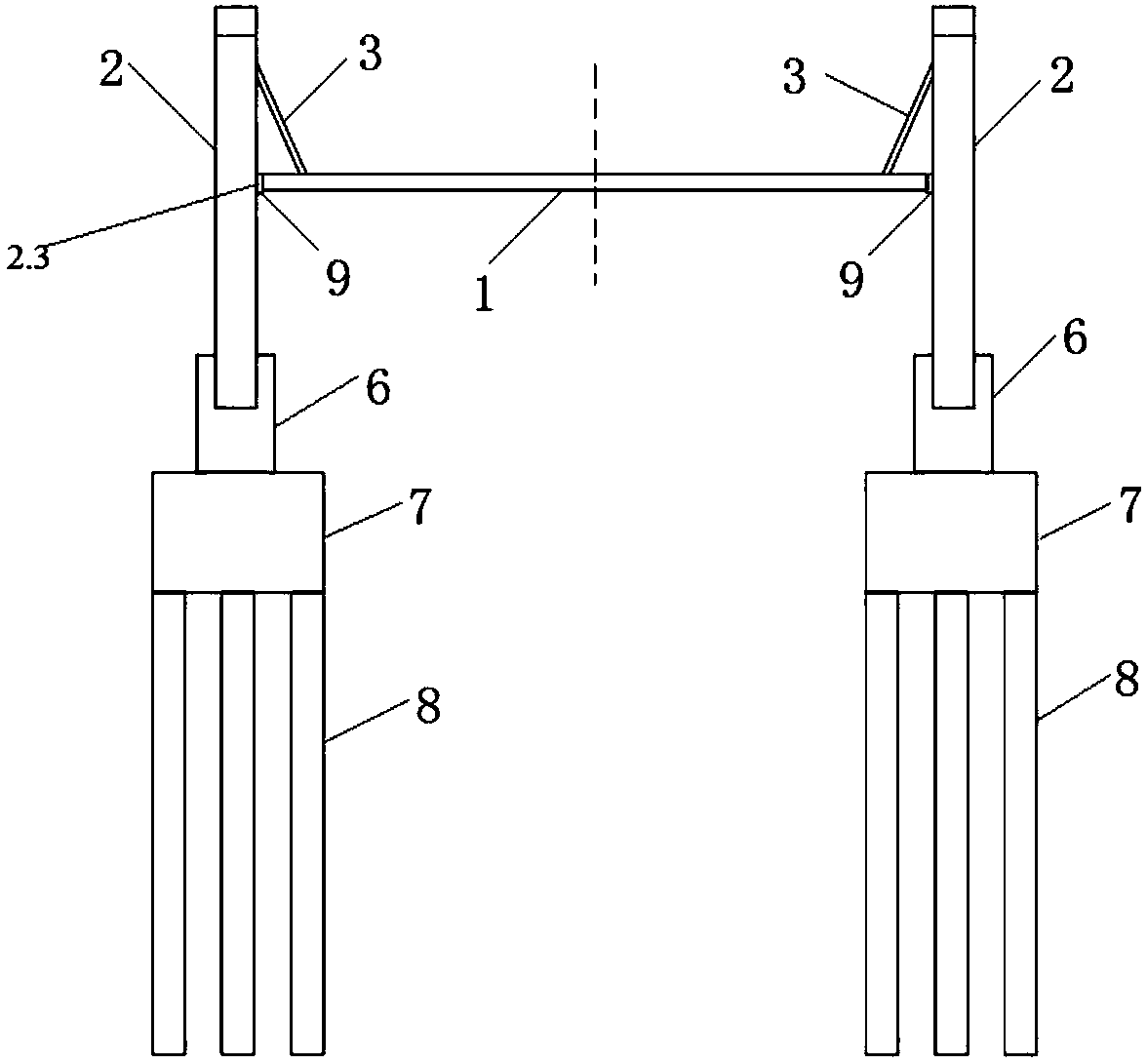

[0049] A bridge with arch and cable-stayed composite system, such as Figure 4 , Figure 5 and Figure 6 As shown, it is a three-span structure, including two side spans and a middle span. The middle span is supported by a mid-span arch rib 2. And the stay cable anchor tower column 5 becomes the load-bearing structure of the whole bridge. The section of the bridge deck 1 between the two sections of the arch rib is the middle span 1.1, and the road surface beyond the two ends of the arch rib is the side span 1.2. A suspender 3 is arranged between the passage surface of the bridge deck and a part of the arch ribs above the passage surface, and the bridge deck is fixed on the arch rib 2 through the suspender 3 .

[0050] It is worth noting that the two arch ribs can be provided with transverse connecting members in the transverse direction, or the two arch ribs can adopt separate arch ribs or basket-type arch ribs. The arch rib adopts structural forms such as reinforced concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com