Integrated crankshaft torsion damper assembly

A torsional shock absorber, integrated technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, portable lifting device, etc., can solve the problem of vibration damping rubber ring shear fatigue, etc., to improve fatigue life and reliability , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

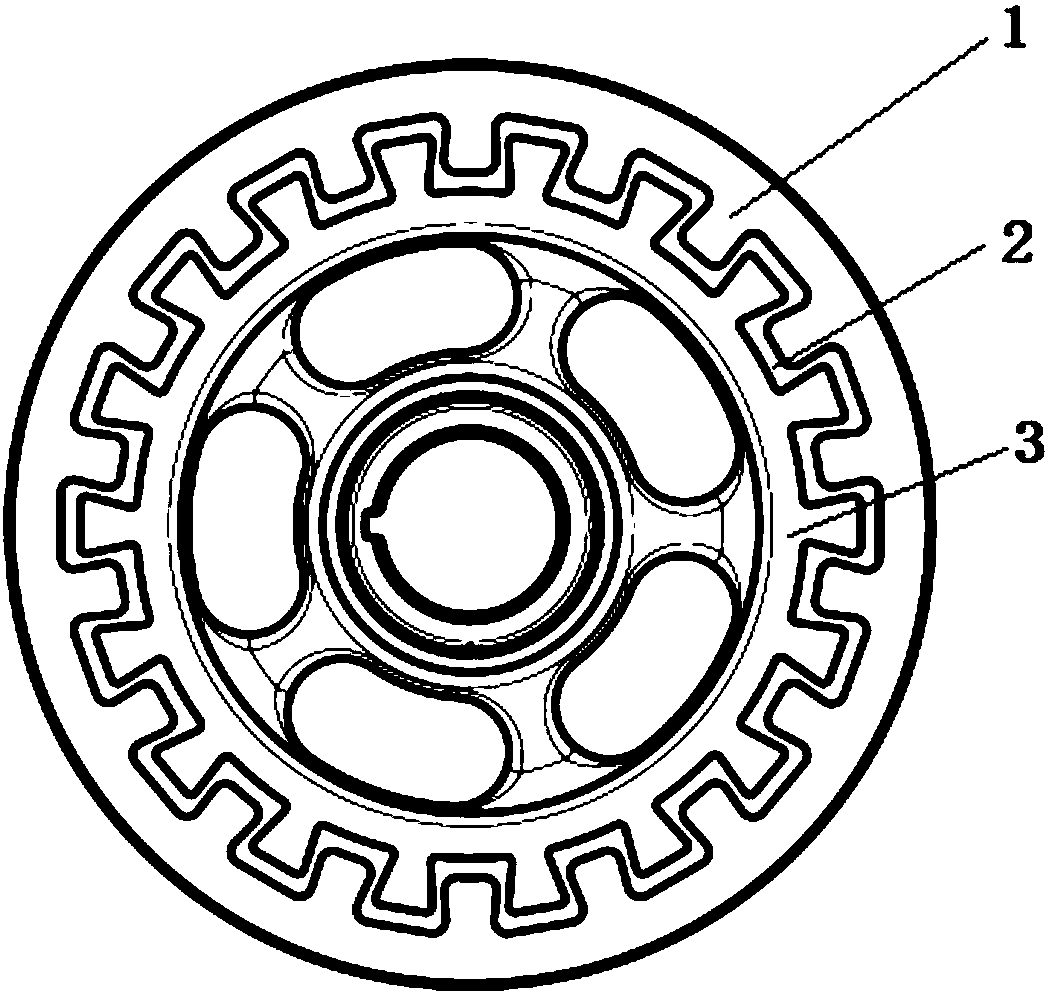

[0021] see figure 1 The one-piece crankshaft torsional damper assembly shown includes a pulley 1 and a hub 3 mated with the crankshaft, and is characterized in that it also includes the inner circle of the pulley 1 and the outer circle of the hub 3 The damping rubber ring 2 between.

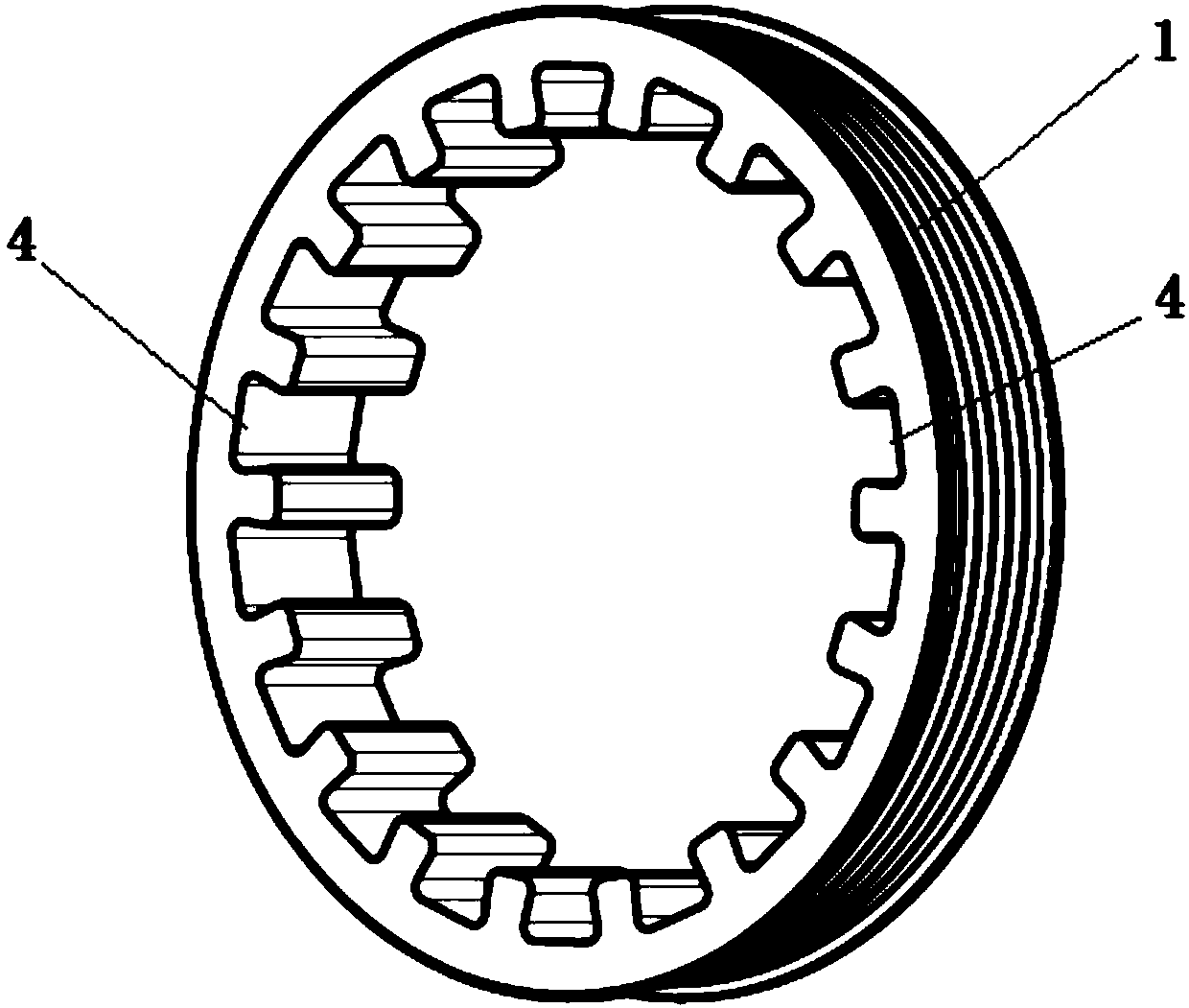

[0022] see figure 2 , the inner circle of the pulley 1 is equidistantly provided with a plurality of large inverted trapezoidal grooves 4 of the same size, and the outer circle is provided with belt grooves.

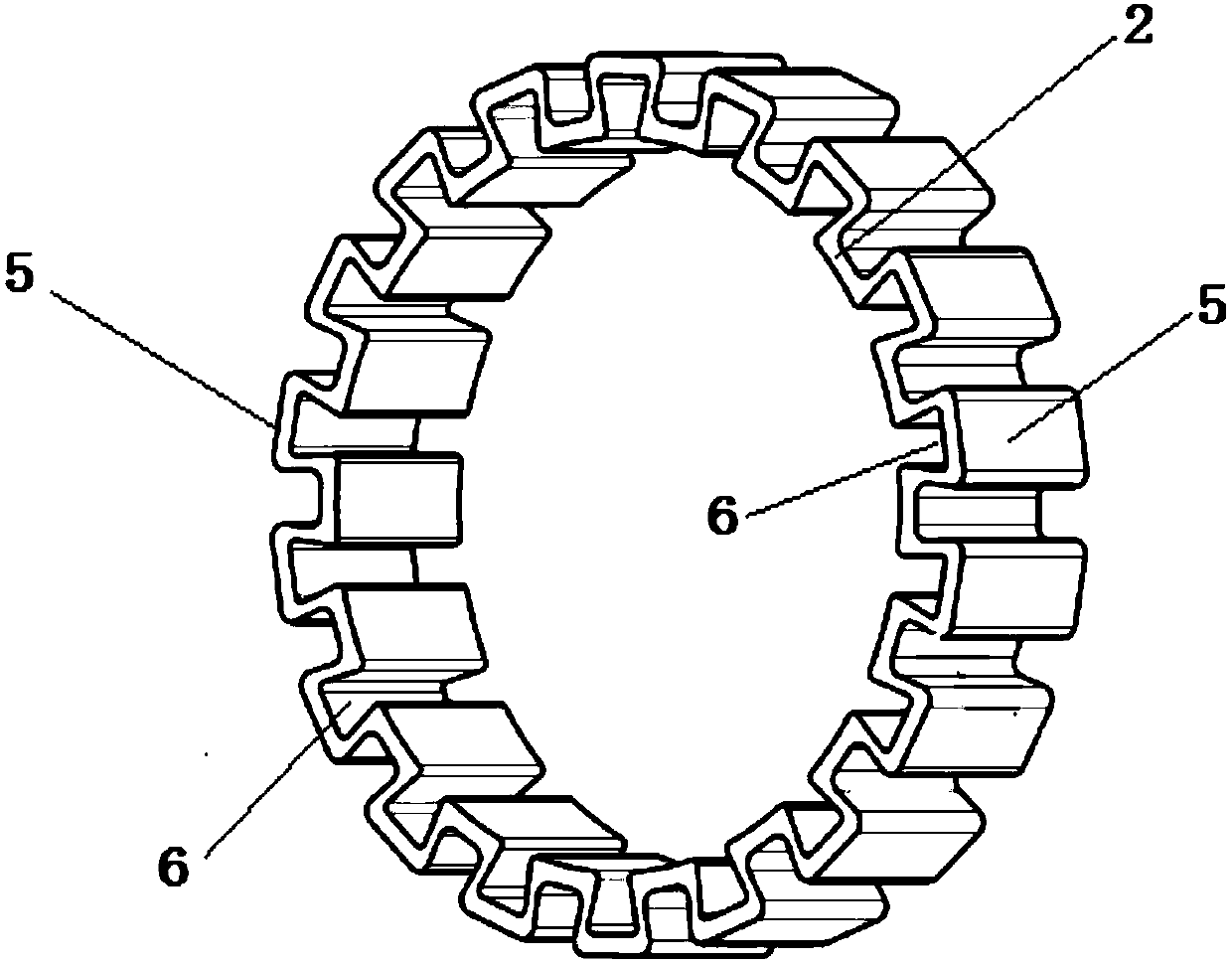

[0023] see image 3 , the outer circle of the damping rubber ring 2 is equidistantly provided with a plurality of large inverted trapezoidal bosses 5 of the same size, and the inner circle is equidistantly provided with a plurality of small inverted trapezoidal grooves 6 of the same size, and the large inverted The number of trapezoidal bosses 5 is equal to the number of said large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com