Motor stator core structure

A technology of motor stator and iron core structure, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of complex heat dissipation structure and insufficient heat dissipation of motor stator, and achieve light weight and good heat dissipation effect. , the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content of the present invention will be described below in conjunction with the accompanying drawings.

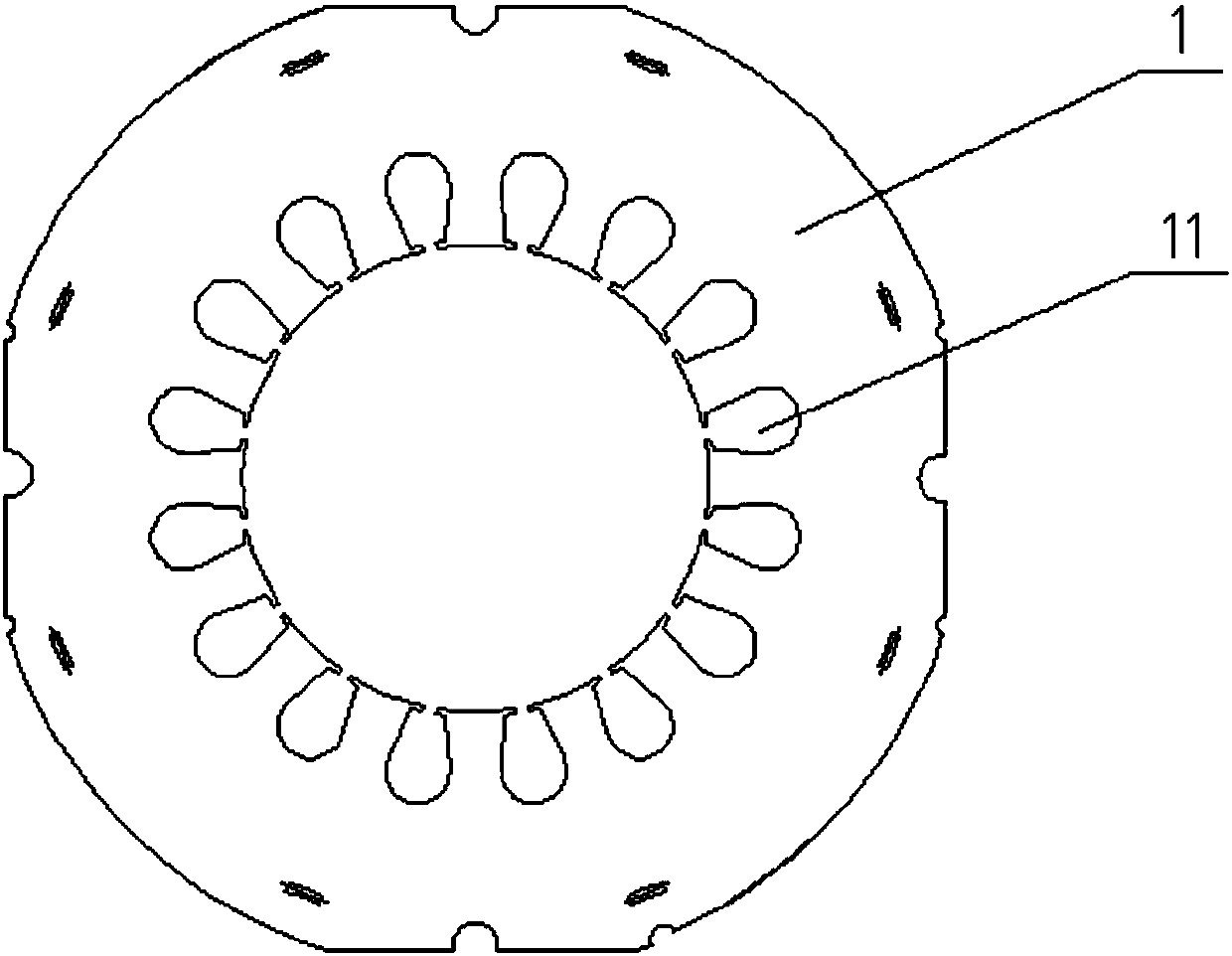

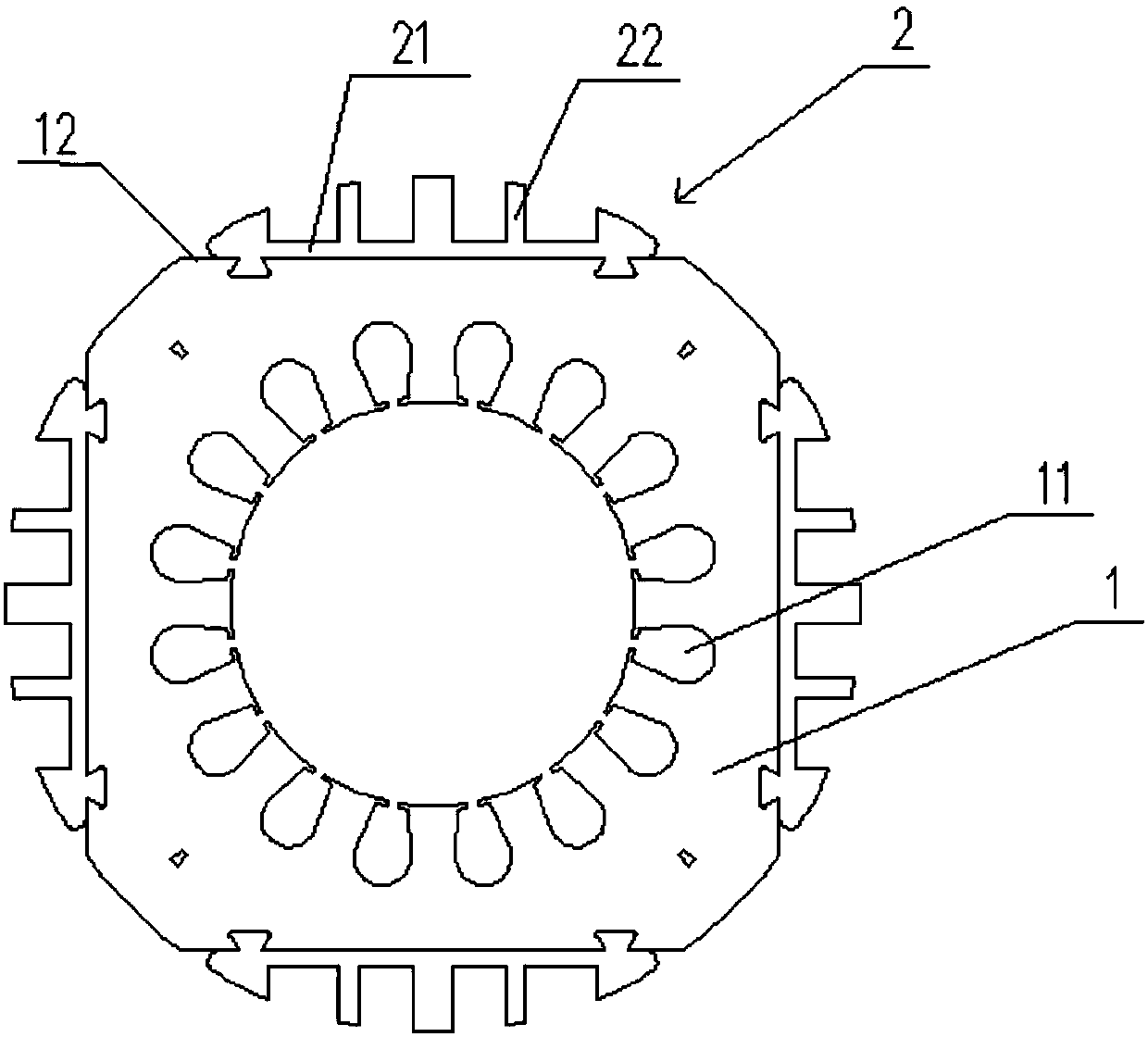

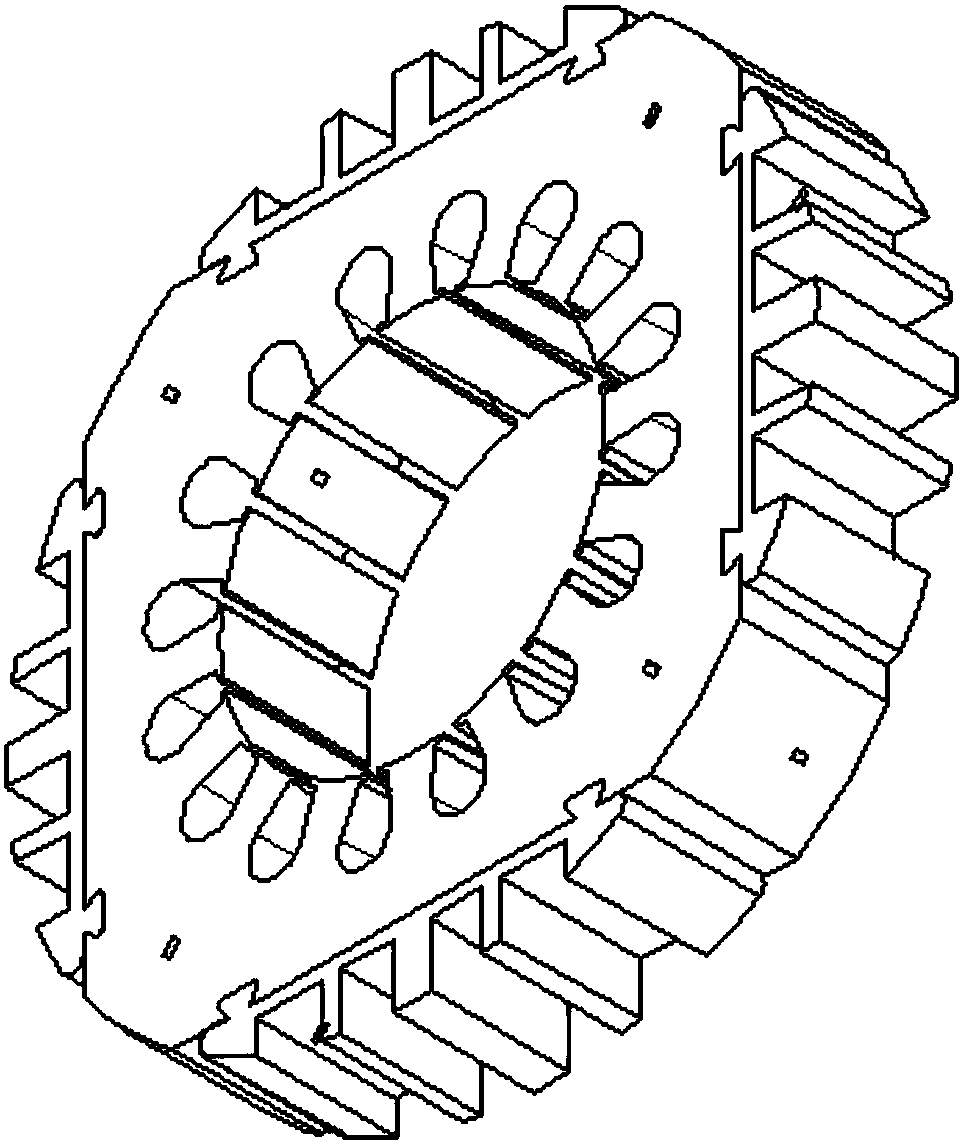

[0027] see Figure 2-3 , a motor stator core structure, including a stator core 1 and a splicing block 2, the cross section of the stator core 1 is circular, the inner ring of the stator core 1 has a stator slot 11, and the stator slot 11 For embedding stator windings, the outer ring of the stator core 1 has cut surfaces 12 corresponding to the number of splicing blocks 2 , and the splicing blocks 2 are spliced with the cut surfaces 12 .

[0028] The side of the splicing block 2 close to the cut surface 12 is adapted to the shape of the cut surface 12, and the shape of the outer ring after the splicing block 2 and the cut surface 12 are spliced is adapted to the shape of the sleeved parts arranged outside the motor stator, Since most of the motors on the market are round and square in shape, the shape of the spliced outer ring here is preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com