Sand discharge method and sand discharge system of cyclone grit chamber

A swirling grit chamber and sand bucket technology, applied in separation methods, chemical instruments and methods, sedimentation separation, etc., can solve problems such as monitoring and discharge of sand without grit chamber, blocking sand and gravel, affecting normal sewage treatment, etc. , to achieve the effect of improving timeliness and initiative and reducing the risk of sand and gravel accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0016] Various embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

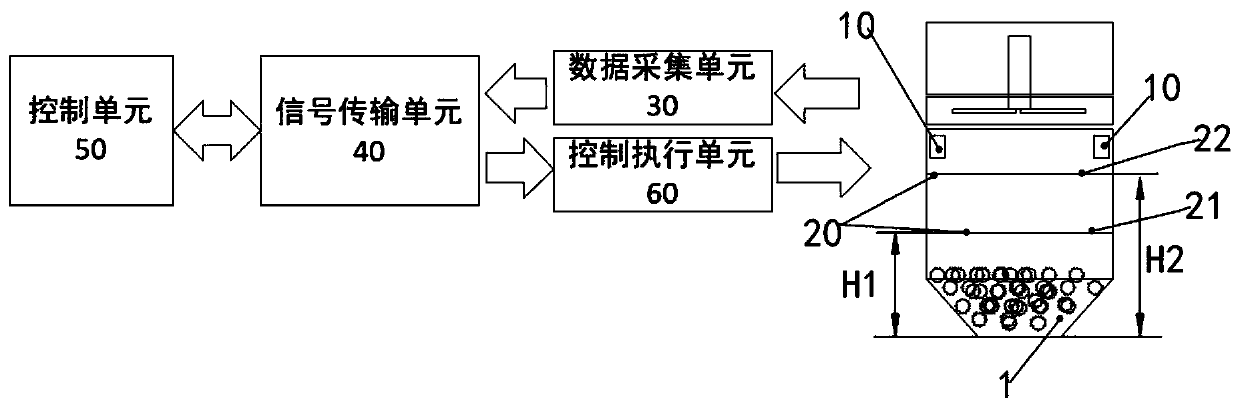

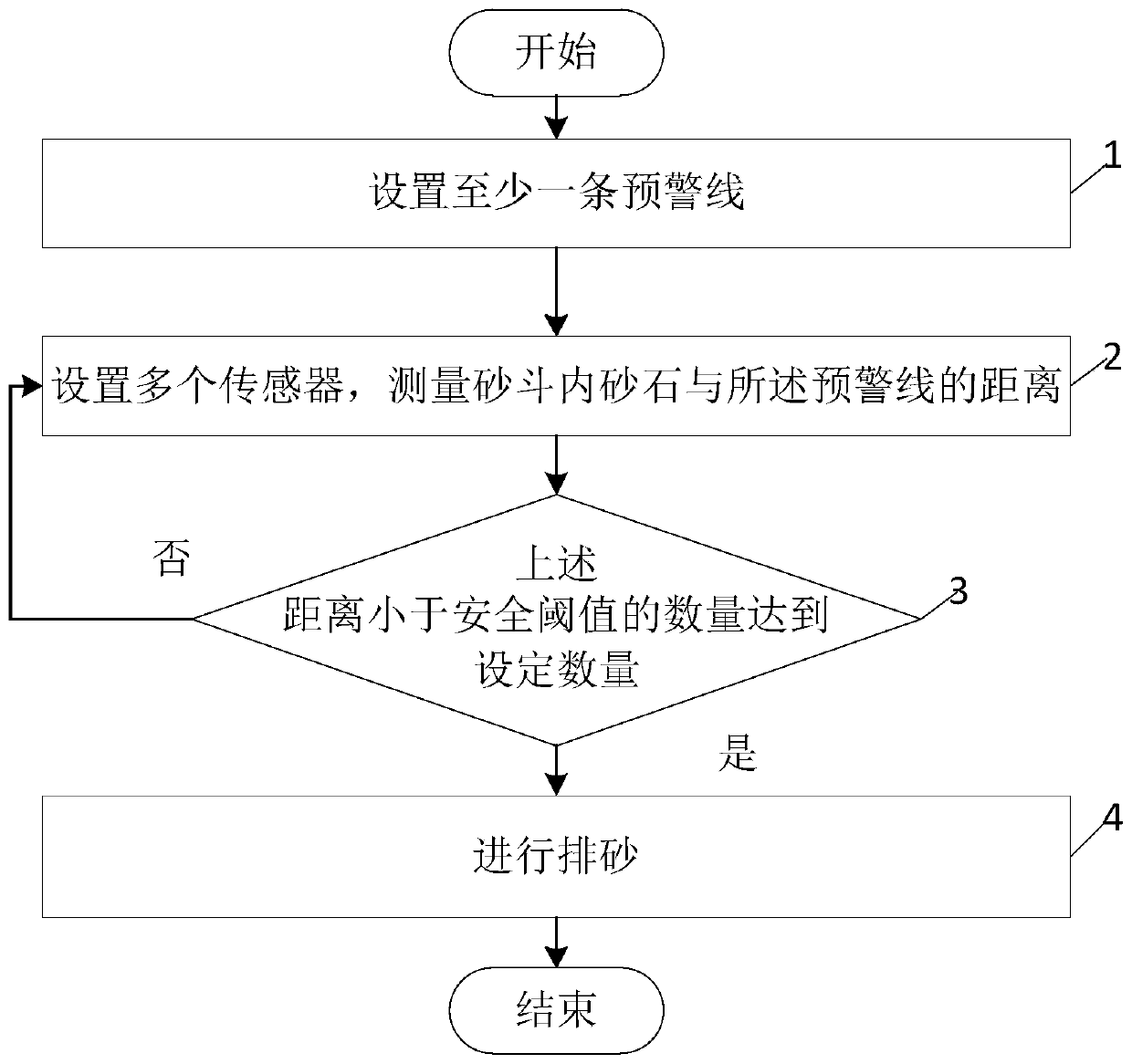

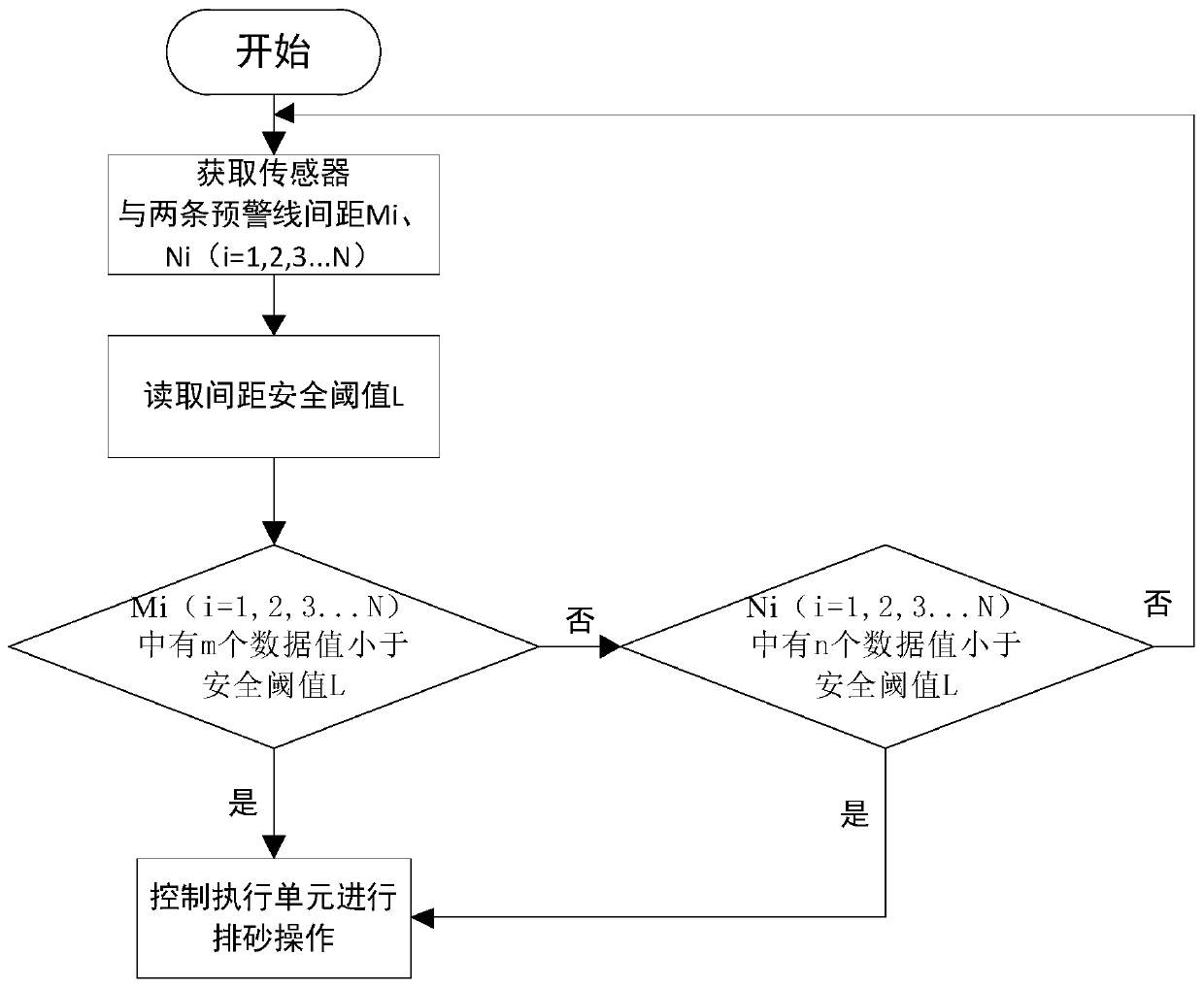

[0017] figure 1 It is a schematic diagram of the sand discharge system of the cyclone grit chamber of the present invention, as figure 1 As shown, the sand discharge system of the cyclone grit chamber is used for the sand discharge of the cyclone grit chamber, and it is characterized in that it includes a plurality of sensors 10, at least one early warning line 20, a data acquisition unit 30, and a signal transmission unit 40 , the control unit 50 and the control execution unit 60, wherein:

[0018] The early warning line 20 is set on the side wall of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com