Special equipment for assembling copper bushes of bearing plates

A special equipment and bearing disc technology, applied in the field of hydraulic pump processing, can solve the problems of manual alignment and pressing copper sleeves, which are time-consuming and labor-intensive, cannot meet industrialized large-scale production, and poor product quality consistency. The effect of saving raw material cost and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

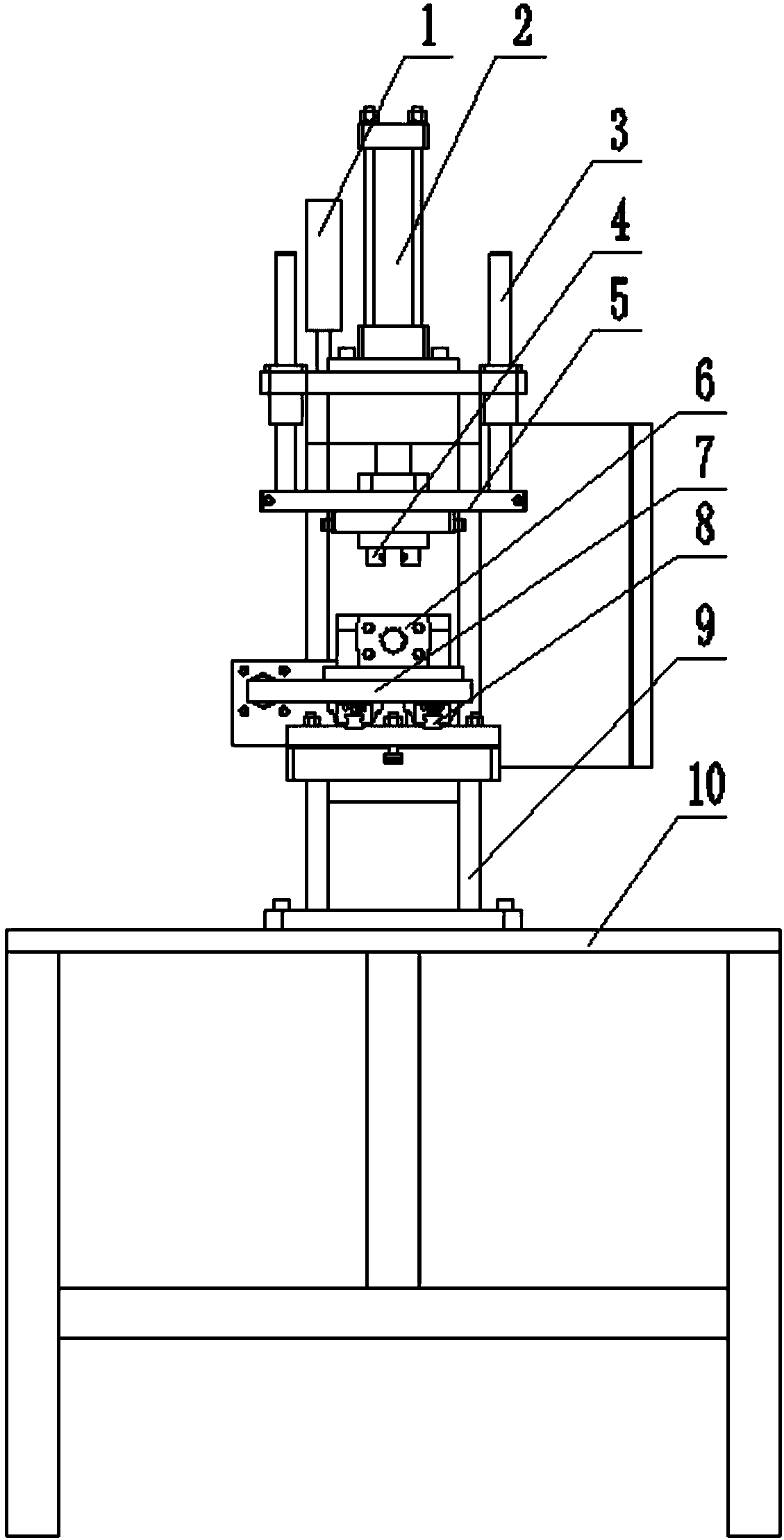

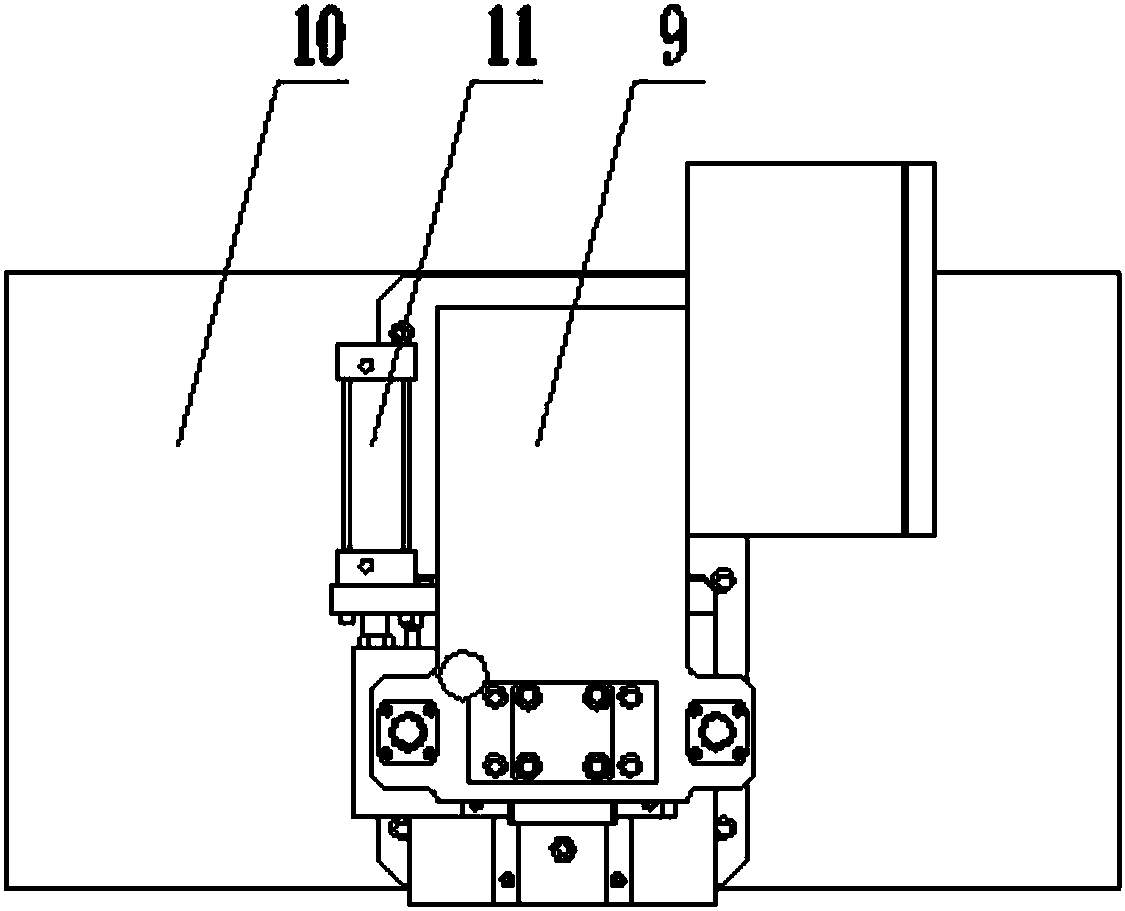

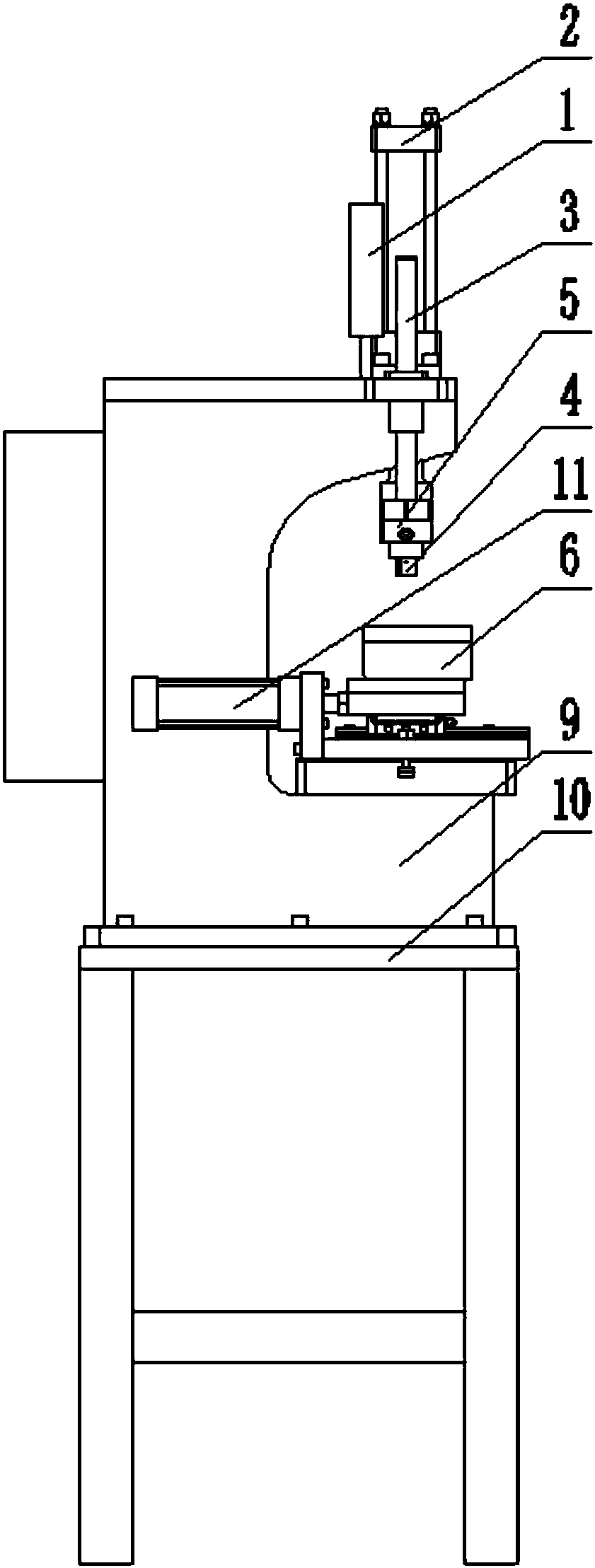

[0023] A special equipment for assembling copper sleeves of bearing discs, including a frame-type support 10, a base 9, a workbench 7, a translation cylinder 11, a lifting hydraulic cylinder 2 and a positioning column 4, the base is installed on the frame-type support, and the Bottom installs a horizontally arranged workbench by linear guide rail 8, and workpiece location bar 12 is installed on the upper surface of this workbench, and location bar is a plurality of vertical settings, and it coincides with the location of the location hole on the bearing disc workpiece. The rear end of the workbench is connected with the piston rod of the translation cylinder, and the translation cylinder is installed on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com