Seat back plate and method for manufacturing same

A production method and backboard technology, which can be applied to other household appliances, household components, applications, etc., can solve the problems of being easily ignited, and the plastic material is heavy and difficult to carry, and achieve good non-flammability, simple structure, and good flame retardancy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

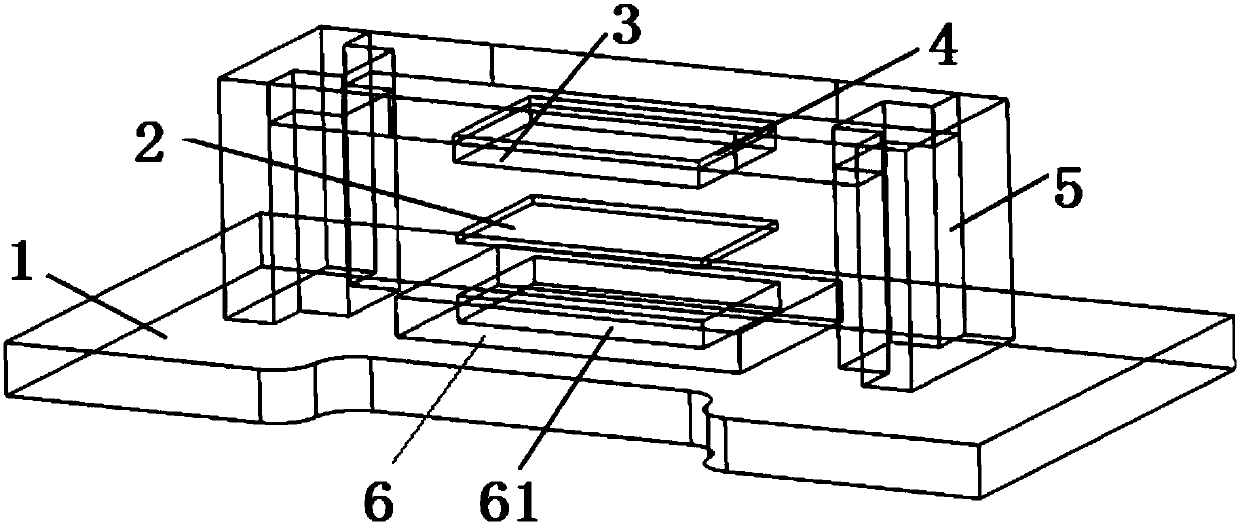

Image

Examples

Embodiment 1

[0043] This embodiment provides a seat backboard, comprising the following components: 1-80 parts by weight of coconut fiber; 1-60 parts by weight of flame-retardant fiber; 1-60 parts by weight of reinforcing fiber.

[0044] Coconut palm fiber has good non-sustainable flame resistance, flame retardant fiber has good flame retardancy at low temperature, and can melt and bond coconut palm fiber and reinforcing fiber at high temperature; the reinforcing fiber plays a role in strengthening the composite The effect of the strength of the composite material makes the final material stronger and lighter in weight.

[0045] The seat backboard made of composite fiber material can be made into a mesh structure, which not only reduces the weight, but also ensures strength and rigidity, and the low-quality seat backboard is easy to move.

[0046] At the same time, the composite fiber material is used to replace the sponge layer, and because of the addition of flame-retardant fibers, it ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com