Quick-drying full and elastic waterproof fabric

A plump and elastic technology, applied in the field of garment processing, can solve the problems of poor waterproofness and quick-drying effect, and achieve the effects of good waterproofness, good air permeability, and low dyeing and finishing weight consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

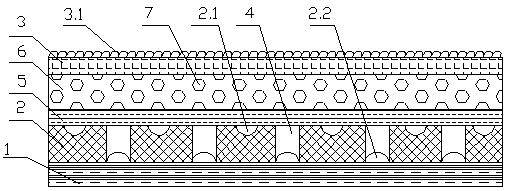

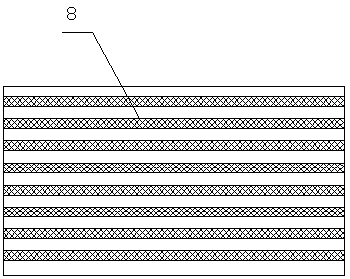

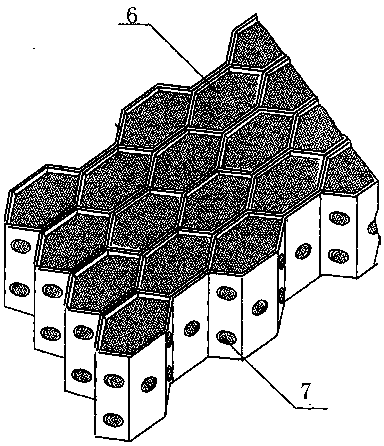

[0012] Such as figure 1 , as shown in 3, a kind of product in the present embodiment is plump and flexible and can perspire quickly waterproof fabric, mainly comprises the inner layer 1 that adopts chemical fiber to make, waterproof layer 2 and the surface layer 3 that adopts natural fiber to make, so The inner layer 1 utilizes different configurations of rib weaves to form a flat surface on one side and a grooved surface 8 on the other side. Part of the grooved surface 8 is in contact with the body, and the flat surface part is interwoven with the waterproof layer 2. The above-mentioned waterproof layer 2 is provided with vent holes 4, and between the described waterproof layer 2 and the surface layer 3, a waterproof breathable film 5 is provided. The air holes 4 make it have good air permeability. A quick-drying layer 6 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com