Reciprocating compression molding system for non-woven fabrics

A technology of compression molding and non-woven fabrics, applied in lamination, lamination devices, layered products, etc., can solve the problems of uneven lamination, affecting the quality of final products, low efficiency, etc., and achieve the effect of uniform lamination force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

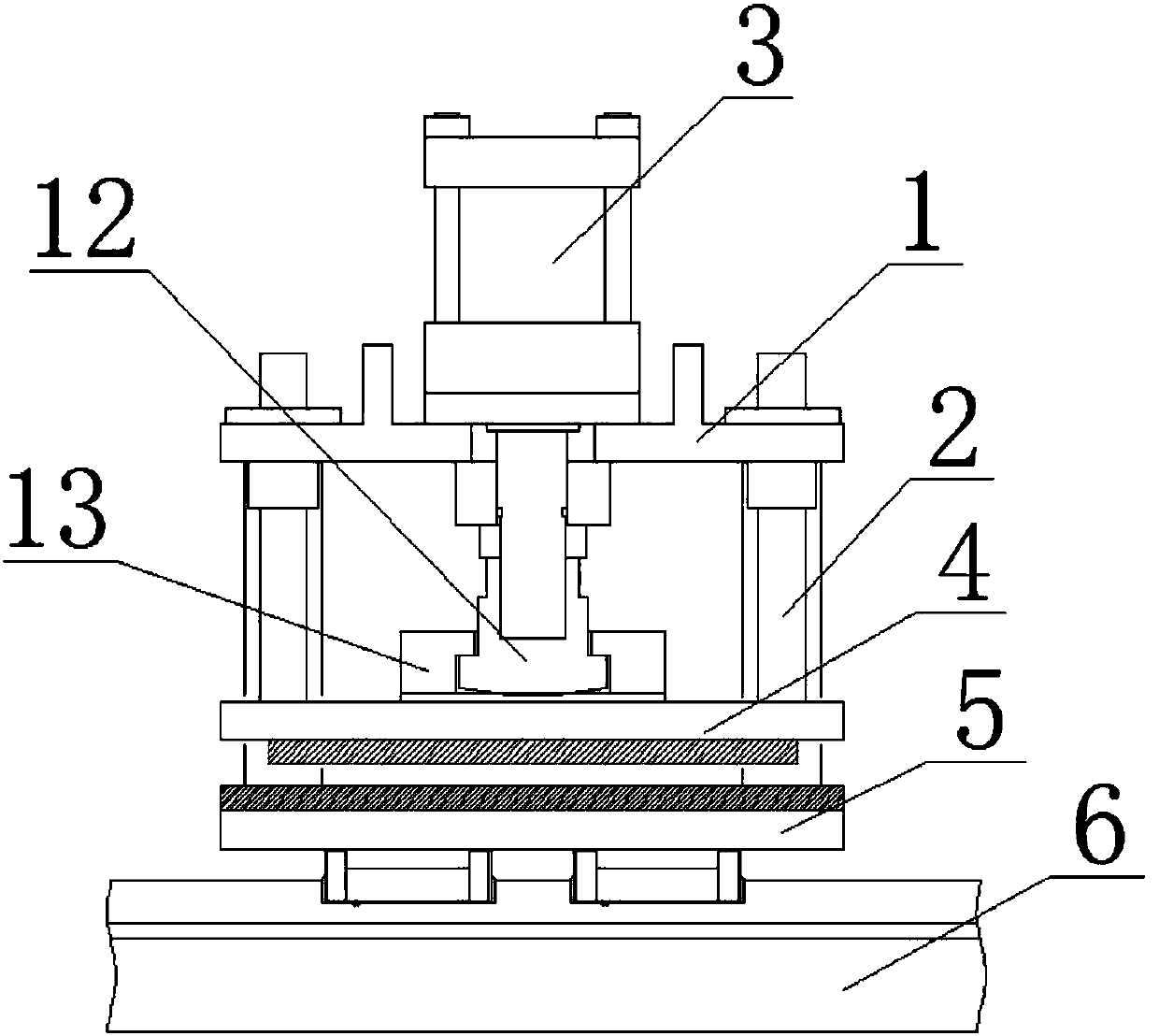

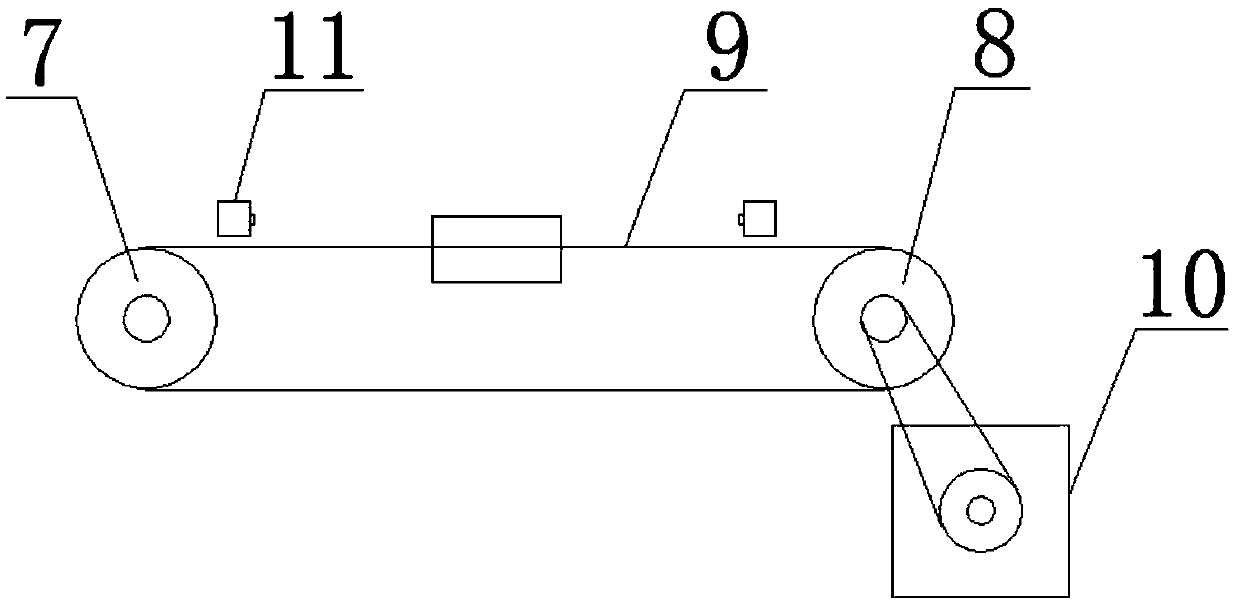

[0018] As shown in the figure, a non-woven fabric reciprocating molding system of the present invention includes a bracket 1, a guide column 2, a cylinder 3, an upper template 4, a lower template 5, a guide rail 6 and a traction mechanism. The cylinder 3 is vertically fixed on the bracket 1 The upper end, the upper template 4 and the lower template 5 are both set horizontally and the upper template 4 is set above the lower template 5, the lower end of the bracket 1 is fixed on the lower template 4, the lower end of the guide post 2 is fixed on the upper side of the upper template 4, and the upper end of the guide post 2 passes through The upper side of the support 1 and the support 1 are slidably arranged, and the upper side of the upper template 4 is connected with the lower end of the piston rod of the cylinder 3 through a movable connecting piece. The movable connecting piece can rotate up and down at any angle in the horizontal direction. The guide rail 6 is arranged along th...

Embodiment 2

[0022] A reciprocating molding system for non-woven fabrics, comprising a bracket 1, a guide column 2, a cylinder 3, an upper template 4, a lower template 5, a guide rail 6 and a traction mechanism. The cylinder 3 is vertically fixed on the upper end of the bracket 1, and the upper template 4 and the lower The template 5 is set horizontally and the upper template 4 is set above the lower template 5. The lower end of the support 1 is fixed on the lower template 4, the lower end of the guide post 2 is fixed on the upper side of the upper template 4, and the upper end of the guide post 2 passes through the upper side of the support 1 and slides with the support 1 The upper side of the upper template 4 is connected with the lower end of the piston rod of the cylinder 3 through a movable connecting piece. The movable connecting piece can be rotated at any angle in the horizontal direction to a certain angle. The guide rail 6 is arranged along the non-woven transmission direction and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com