Full-automatic sealing machine and application thereof

A cup sealing machine, fully automatic technology, used in packaging sealing/fastening, external support, transportation packaging, etc. efficiency, low cost, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

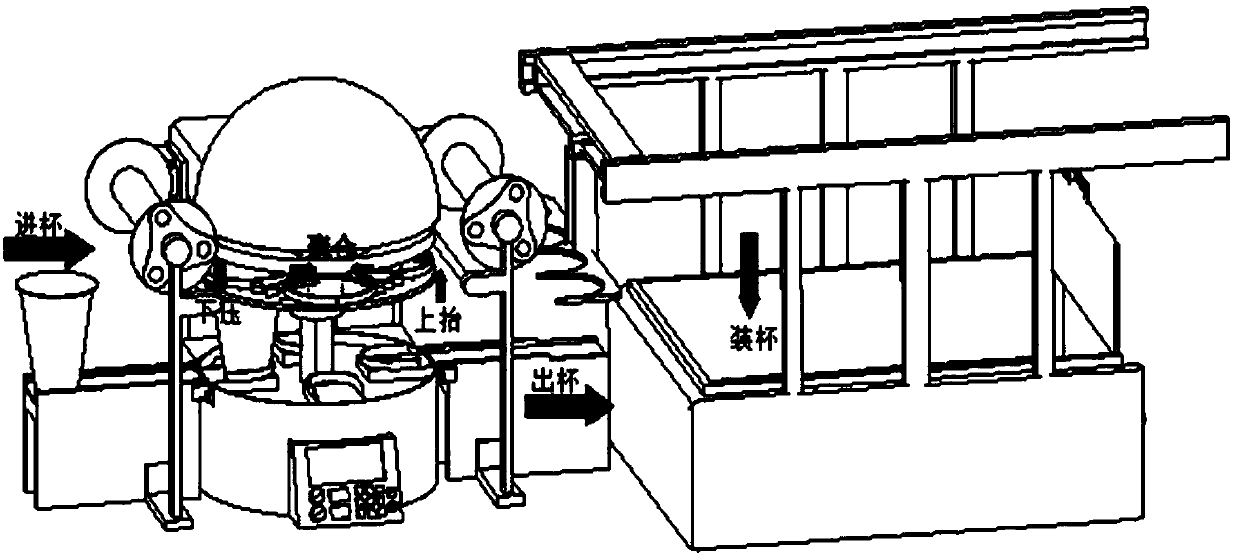

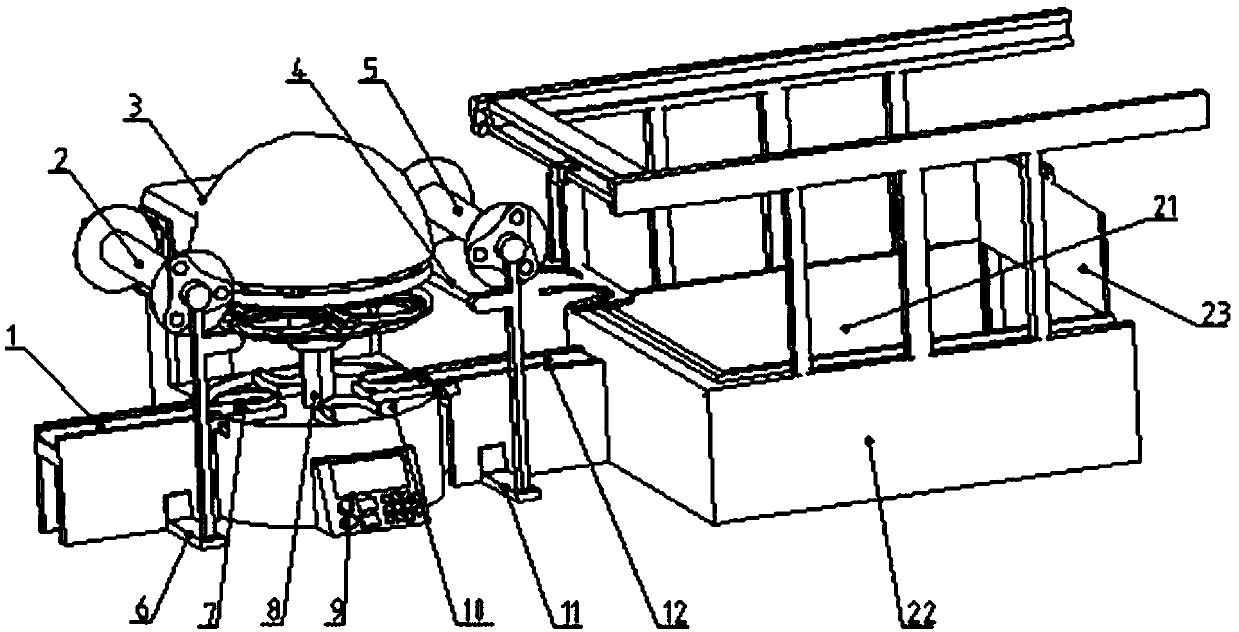

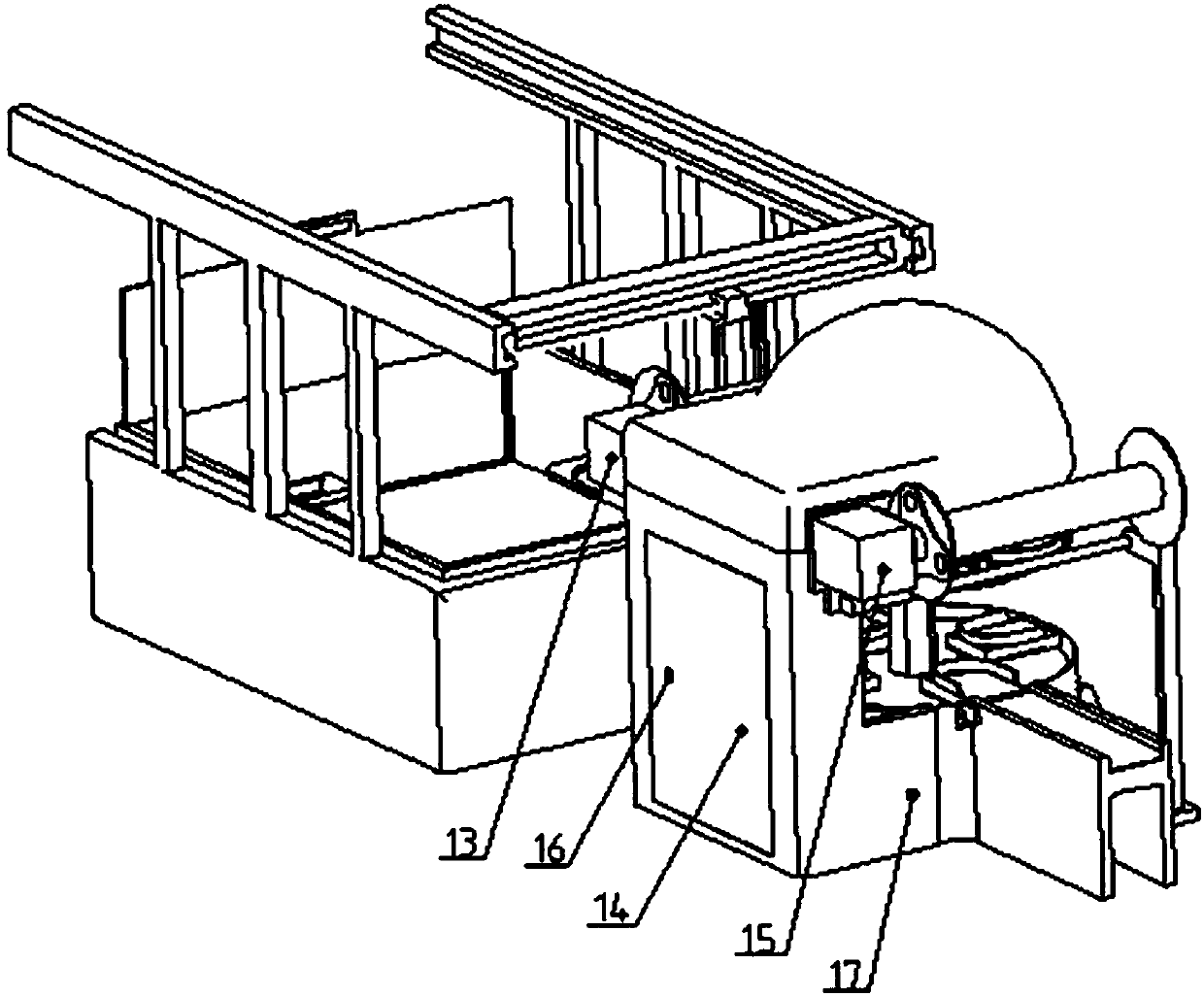

[0051] This embodiment provides a fully automatic cup sealing machine, which mainly includes five parts: a cup feeding part, a film feeding part, a film pressing part, a cup output part and a packing part; wherein,

[0052] The cup feeding part includes the carrying conveyor belt 1, which transports the cups to the laminating part; the carrying conveyor belt 1 adopts a micro-belt conveyor, and the belt rotates continuously under the drive of the front and rear two belt rollers, and the belt roller at one end is driven by the motor. The drive is the driving roller, and the belt at the end of the driving roller is closely connected with the laminating part; when in use, the beverage cup filled with beverages is directly placed on the belt, and the rotating belt drives the drinking cup forward into the laminating part.

[0053] The film feeding part is used to provide the sealing film to the lamination part; the film feeding part mainly includes two transmission parts arranged opp...

Embodiment 2

[0063] A fully automatic cup sealing machine, the structure of which is as described in Embodiment 1, the difference is that auxiliary conveyor belts are provided between the carry conveyor belt 1 and the working position conveyor belt 7, and the output conveyor belt 12 and the working position conveyor belt 7. The two ends of the in-out position shaft 51 and the auxiliary in-out position shaft 51 are equipped with bearings 52, and the bearings 52 are installed on the bearing seats 53 on both sides of the micro-belt conveyor. And maintain the same line speed with the conveyor belts on both sides. The auxiliary entry and exit shaft 51 can be effectively connected between the two, so that the beverage cups before and after the sealing film can be smoothly transferred on the belt.

Embodiment 3

[0065] A kind of working method of automatic cup sealing machine as described in embodiment 2, comprises the following steps:

[0066] (1) Start the automatic cup sealing machine, put the filled cup on the carrying conveyor belt 1, and the rotating belt transports the cup to the working station conveyor belt 7;

[0067] (2) The working platform 10 rotates, so that the next working station conveyor belt 7 rotates to the position where it meets the carrying conveyor belt 1, and the next cup enters the working station conveyor belt 7, and the working platform 10 rotates in turn to make the subsequent cups enter the four working positions. on the conveyor belt 7;

[0068] (3) The bayonet assembly is lowered so that the mouth of the cup enters the through hole on the sliding mold clamping platform 41, and then the bayonet device moves, the sliding mold clamping A44 and the sliding mold clamping B45 move towards each other and finally clamp the cup mouth;

[0069] (4) The sealing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com