Concrete and production method and construction method

A concrete and pre-mixing technology, which is applied to the cohesive pavement paved on site, buildings, roads, etc., can solve the problems that cannot meet the needs of use, achieve good structural strength, improve structural strength, and improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A construction method for producing concrete and concrete pavement, comprising the following steps:

[0048] Step 1. Premixing: put 160 parts of Portland cement, 400 parts of pumice, 80 parts of fly ash, and 200 parts of yellow sand into the mixing equipment and stir until uniform. The speed of the mixing equipment is 26r / min. The mixing time is 7 minutes to form pre-mixed concrete;

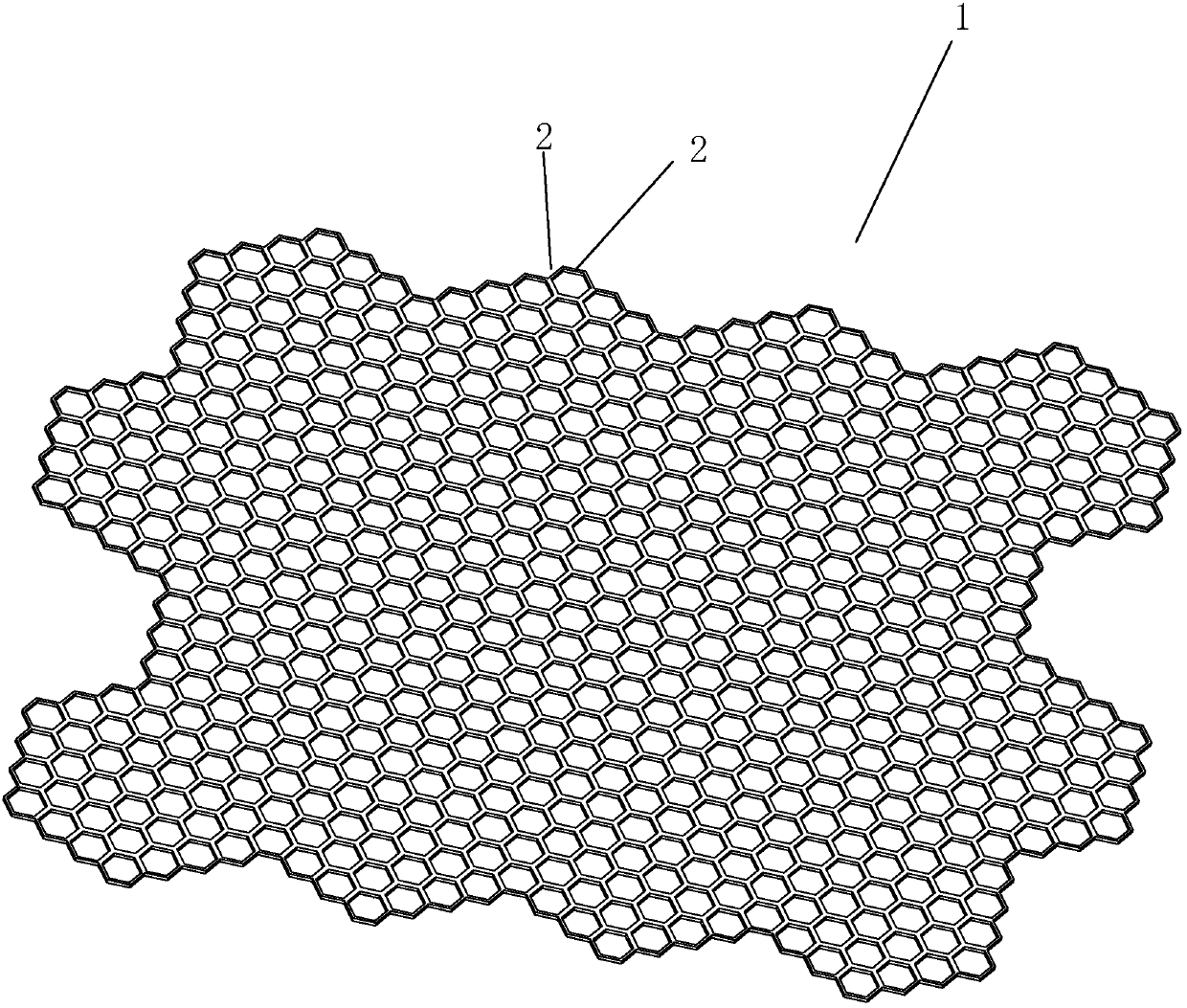

[0049] Step 2: Injection molding ABS by injection molding machine such as figure 1 As shown in the mesh plastic 1, the mesh plastic 1 includes several interconnected branches 2, and the diameter of each branch 2 is 5 mm;

[0050] Step 3. Remixing: Put the mesh plastic 1 into the pre-mixed concrete in the mixing equipment. The rotation speed of the mixing equipment is 2r / min, and the mixing time of the mixing equipment is 4 minutes. Stir until it is uniform to form the finished concrete. The volume of reticulated plastic 1 is 0.1m³ per 1m³ of finished concrete on average.

[0051] Step 4...

Embodiment 2

[0056] A construction method for producing concrete and concrete pavement, comprising the following steps:

[0057] Step 1. Pre-mixing: Put 190 parts of Portland cement, 150 parts of light sand, 80 parts of fly ash, and 300 parts of yellow sand into the mixing equipment and stir until uniform. The speed of the mixing equipment is 20r / min. The mixing time of the equipment is 4 minutes to form pre-mixed concrete;

[0058] Step 2: Injection molding PS by injection molding machine such as figure 1 As shown in the mesh plastic 1, the mesh plastic 1 includes several interconnected branches 2, and the diameter of each branch 2 is 1mm;

[0059] Step 3. Remixing: Put the mesh plastic 1 into the premixed concrete placed in the mixing equipment. The rotation speed of the mixing equipment is 10r / min, and the mixing time of the mixing equipment is 3 minutes. Stir until it is uniform to form the finished concrete. The volume of reticulated plastic 1 is 0.1m³ per 1m³ of finished concrete o...

Embodiment 3

[0065] A construction method for producing concrete and concrete pavement, comprising the following steps:

[0066] Step 1. Pre-mixing: Put 175 parts of Portland cement, 300 parts of volcanic ash, 70 parts of fly ash, and 260 parts of yellow sand into the mixing equipment and stir until uniform. The speed of the mixing equipment is 22r / min. The mixing time is 6 minutes to form pre-mixed concrete;

[0067] Step 2: Injection molding PP through an injection molding machine such as figure 1 As shown in the mesh plastic 1, the mesh plastic 1 includes several interconnected branches 2, and the diameter of each branch 2 is 3 mm;

[0068] Step 3. Remixing: Put the mesh plastic 1 into the premixed concrete placed in the mixing equipment. The rotation speed of the mixing equipment is 11r / min, and the mixing time of the mixing equipment is 4 minutes. Stir until it is uniform to form the finished concrete. The volume of shaped plastic 1 is 0.1m³ per 1m³ of finished concrete on average. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com