Washing-machine detergent putting device and washing machine

A detergent injection and washing machine technology, which is applied in the field of washing machines, can solve the problems of large installation space, increased maintenance costs, and poor experience effects, and achieve the effects of simplifying the structure, reducing maintenance costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

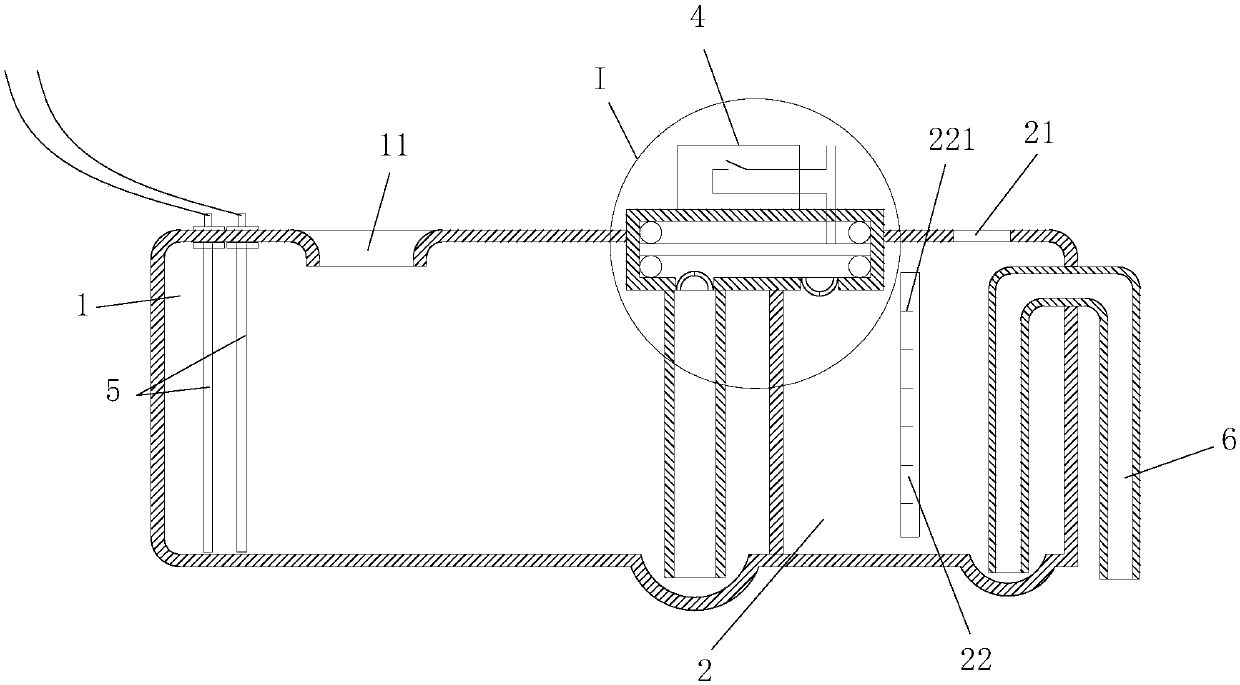

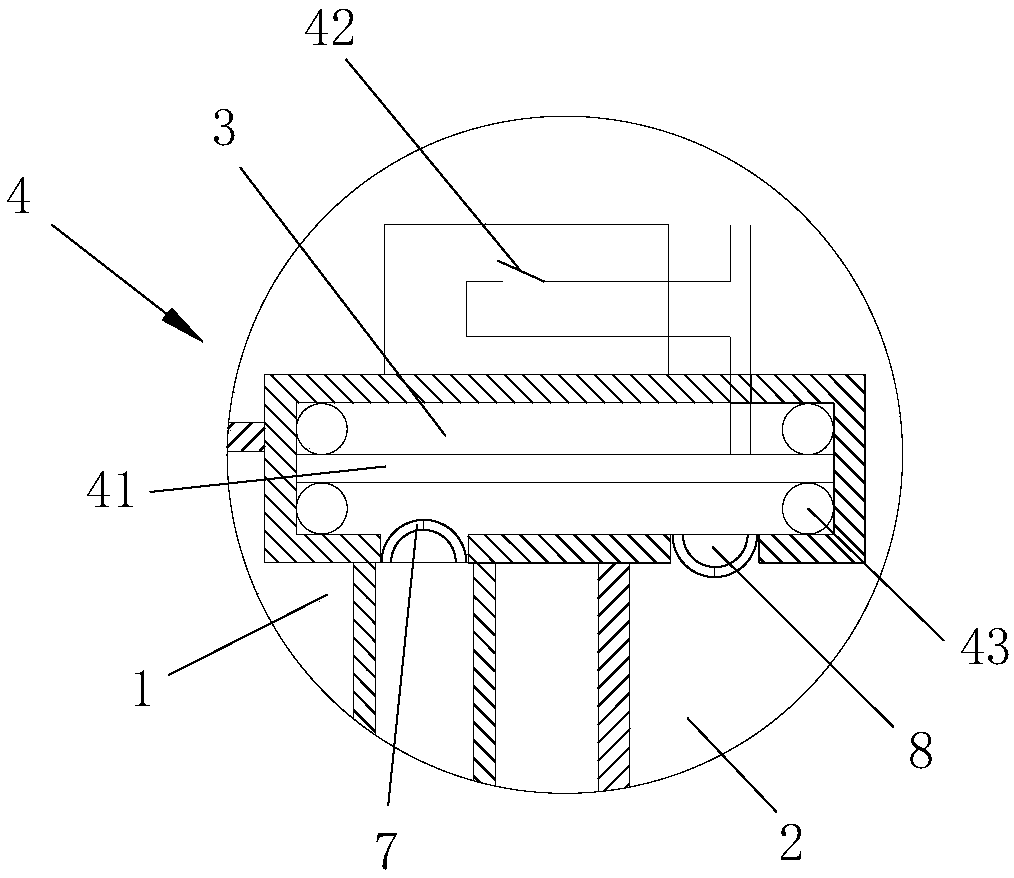

[0024] figure 1 It is a schematic structural diagram of the detergent dispensing device for washing machine provided in this embodiment, and the user can realize semi-automatic dispensing of detergent through the detergent dispensing device described in this embodiment.

[0025] The detergent dispensing device described in this embodiment includes a liquid storage chamber 1 provided with a discharge port 11, a constant volume chamber 2 provided with a water inlet 21 and communicated with the inner barrel of the washing machine, and connected to the liquid storage chamber 1 and the constant volume chamber through a one-way valve. The working chamber 3 connected to the chamber 2, and the power assembly 4 that repeatedly changes the pressure in the working chamber 3; by changing the pressure in the working chamber 3, the detergent in the liquid storage chamber 1 is sent into the constant volume chamber 2 through the working chamber 3 And enter the inner drum of the washing machin...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the switch 42 is connected to the controller, and the addition of detergent is integrated into the laundry program as a program, that is, the laundry program includes adding detergent, washing, rinsing and dehydration, and can be adjusted according to the clothes. Choose the amount of detergent to be added according to the amount of detergent and the degree of dirt. There is no need to manually turn on and off the switch 42, and the amount of detergent added is accurately controlled by the controller, so as to realize fully automatic injection of detergent. Other structures described in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0035] This embodiment also provides a washing machine, including the above-mentioned detergent dispensing device for a washing machine. The washing machine realizes automatic injection of detergent through the above-mentioned detergent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com