Geogrid reinforced earth retaining wall based on construction waste and construction method

A technology of geogrid reinforcement and construction slag, which is applied in the field of reinforced soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

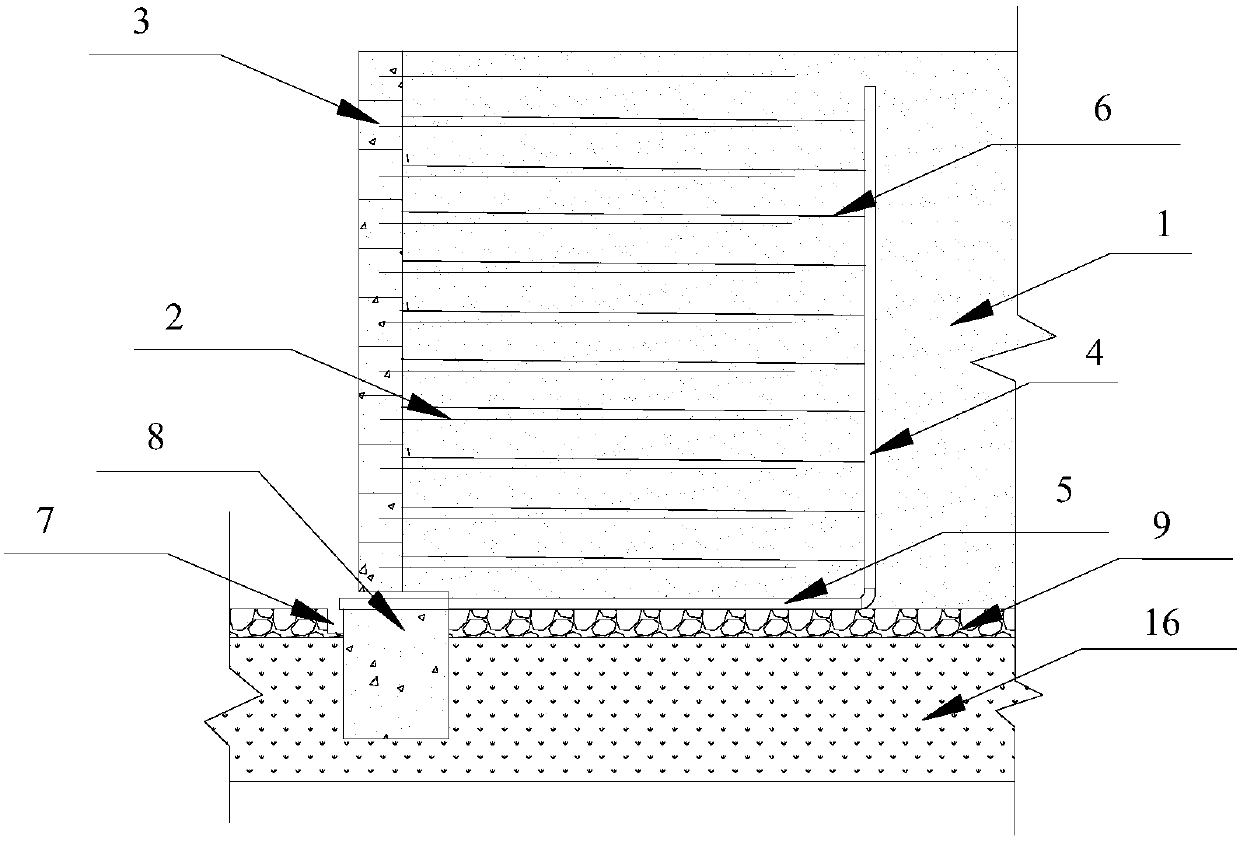

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in further detail:

[0021] 1. Remove debris on the surface, excavate the foundation, compact the base, and lay a gravel cushion (9) on the flat and compacted foundation. The gravel cushion (9) should exceed the reinforced soil retaining wall strip The outer side of the shaped foundation (9) is more than 1m, and the positions of the reinforced concrete strip foundation (8) and the drainage ditch (7) should be reserved, and the reinforced concrete strip foundation (9) should be poured at the reserved position Foundation (8) and gutter (7).

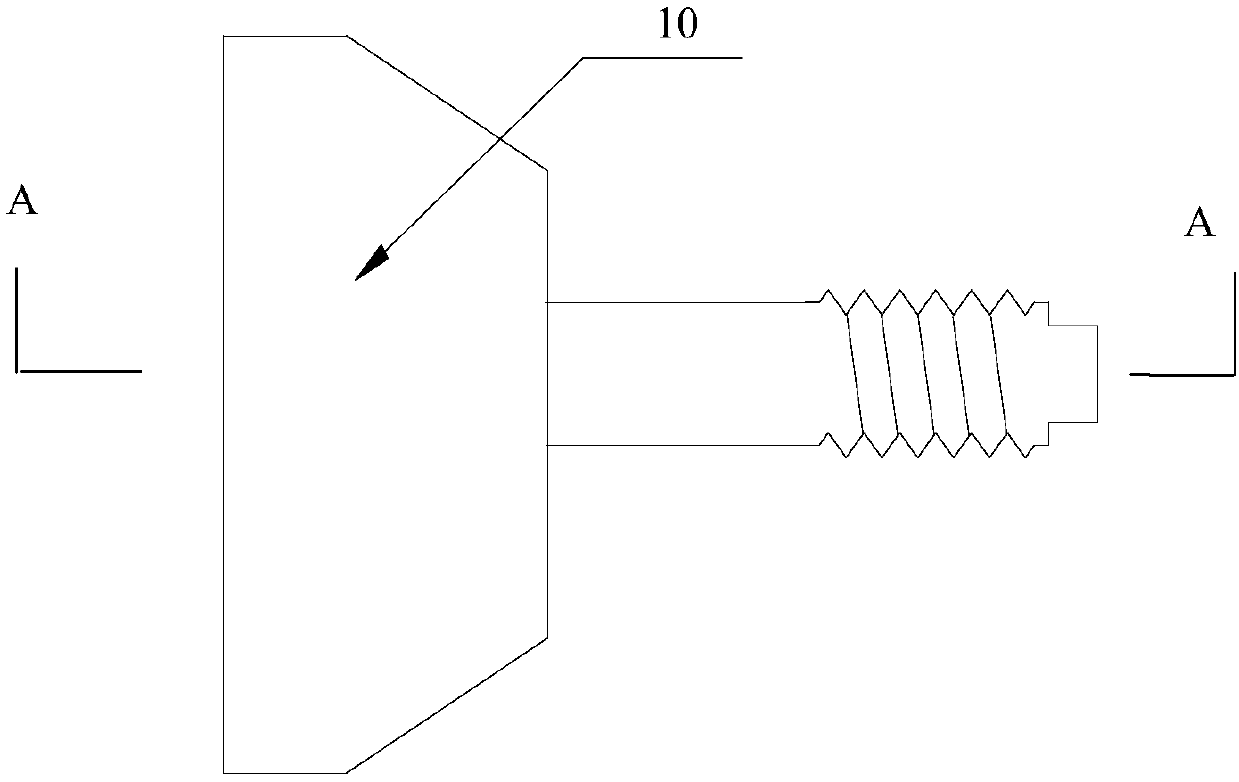

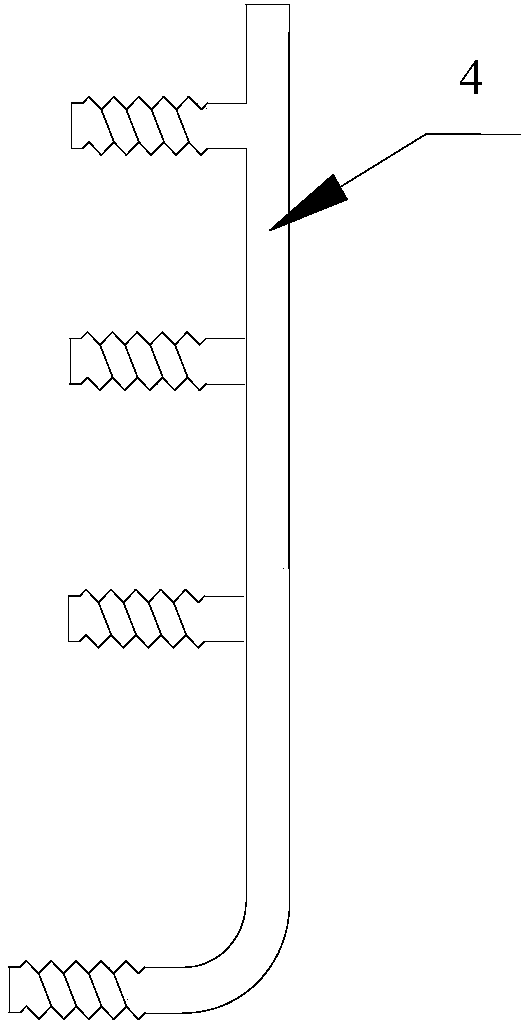

[0022] 2. Install the horizontal drainage pipe (5) and the first layer of vertical drainage pipe (4) on the gravel cushion (9), and use the sleeve (15) to connect the first layer of vertical drainage pipe (4) to the horizontal drainage pipe. The tubes (5) are connected as a whole.

[0023] 3. Fill the construction dregs filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com