Supercharged internal combustion engine with compressor, exhaust-gas recirculation arrangement and flap

An internal combustion engine, exhaust gas recirculation technology, applied in the direction of internal combustion piston engine, combustion engine, exhaust gas recirculation, etc., can solve the problems of low turbine pressure ratio, reduced boost pressure ratio, small exhaust gas mass flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

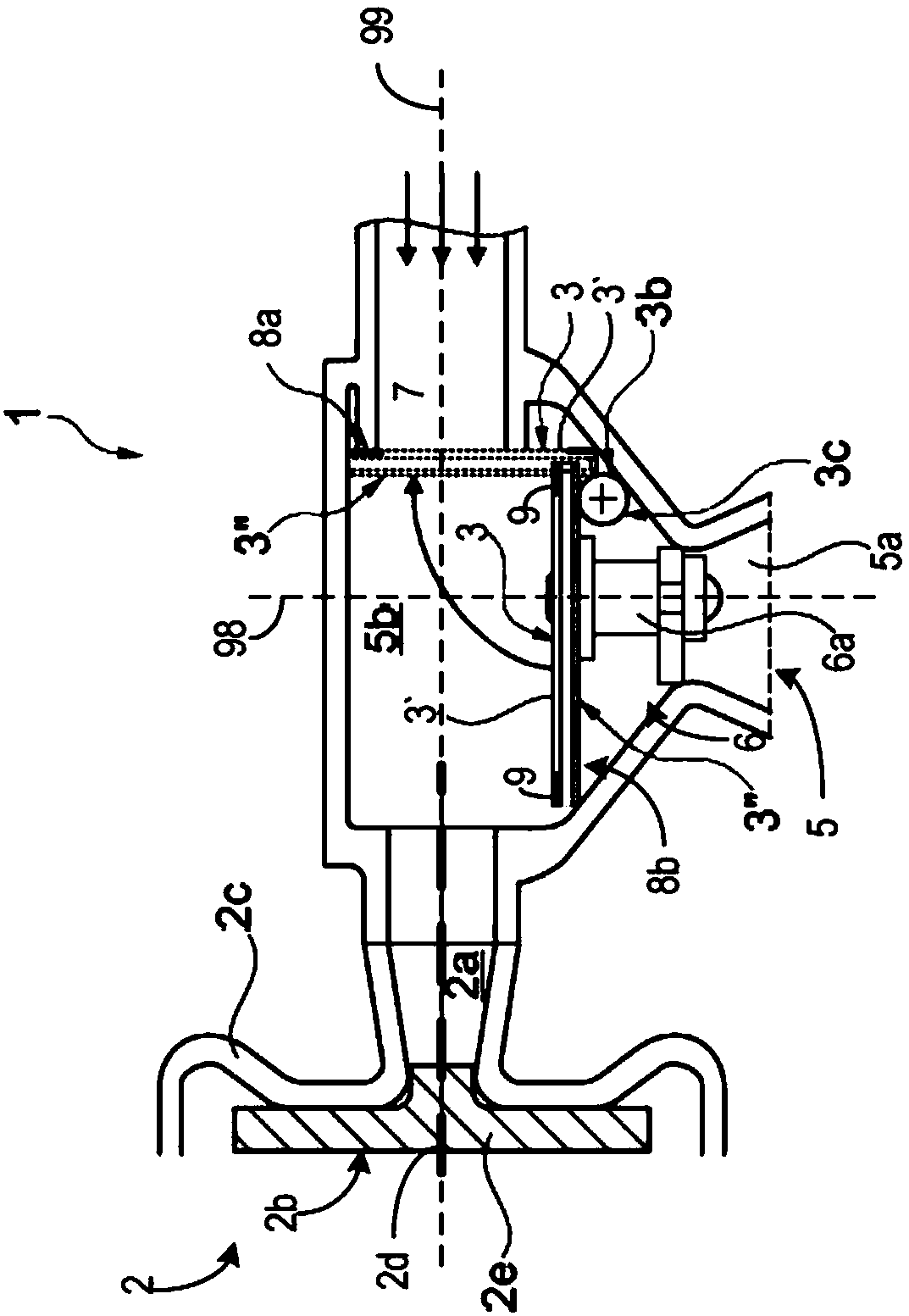

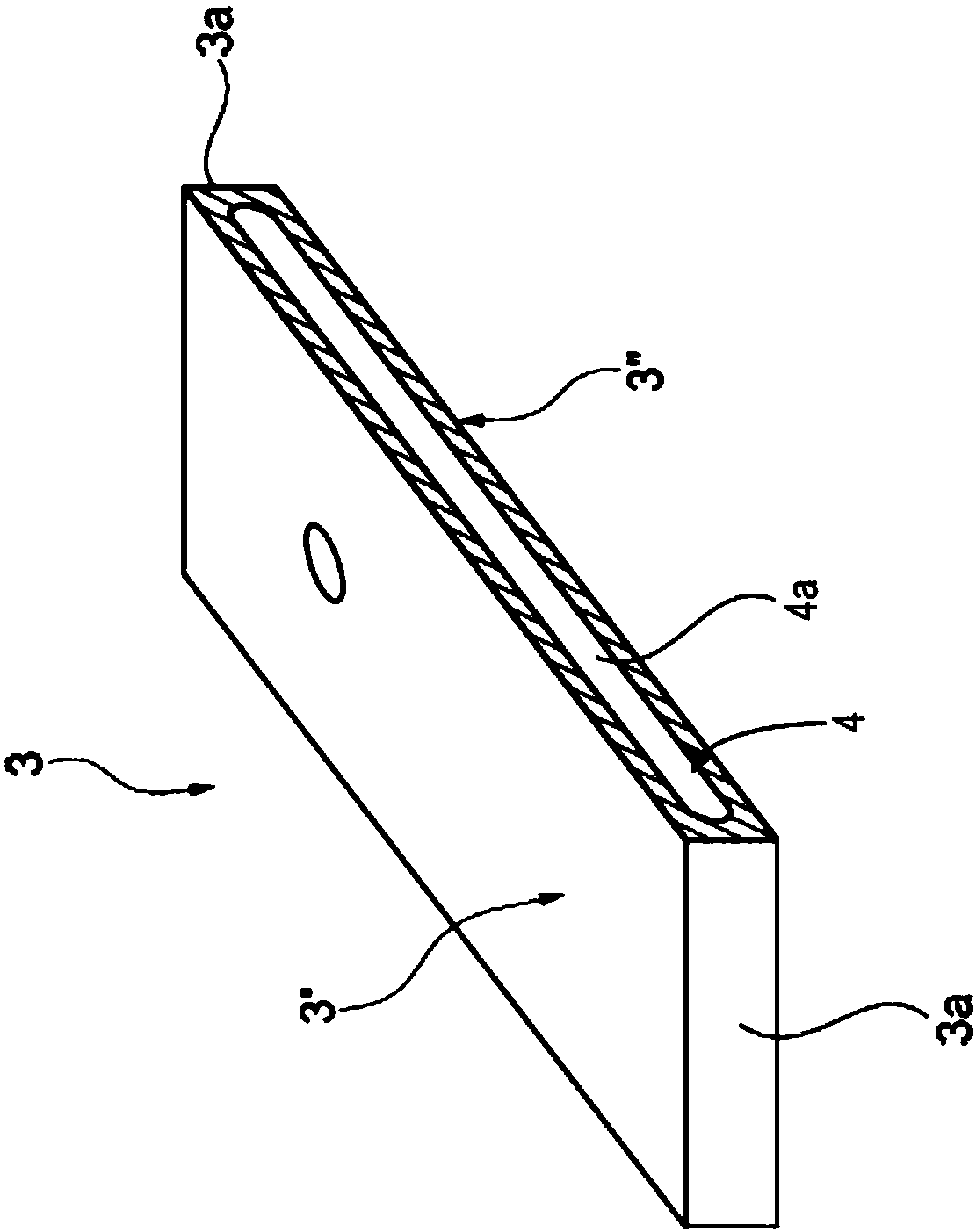

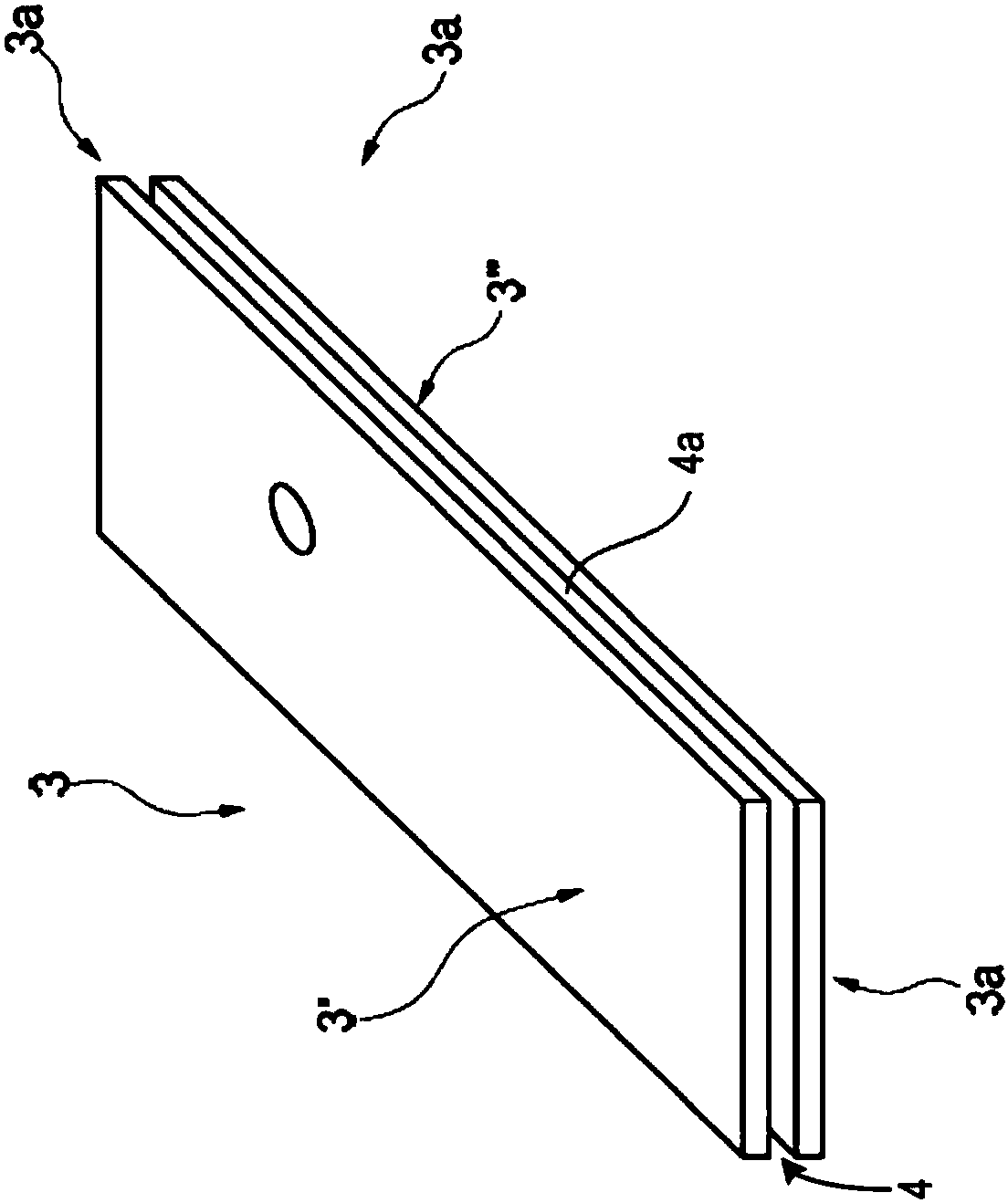

[0041] The following description relates to systems and methods for flap valves. The flap valve may be a substantially planar valve configured to regulate gas flow through the intake passage to the engine. Such as Figure 1A As shown, the flap valve can be adjusted to a first position, a second position, and one or more positions therebetween. In one example, the first position corresponds to a fully open position of the valve where intake air can freely flow to the engine. The second position corresponds to a fully closed position of the valve in which intake air flow to the engine is substantially zero.

[0042] The flap valve also includes an insulating portion coupled to the actuator of the flap valve such that the insulating portion can pivot and / or rotate with the flap valve. The insulating portion may be configured to thermally isolate the flap valve. For example, an insulating portion may be arranged between the flap valve and an outlet of low pressure exhaust gas r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com