Flame-retardant and cold-resistant power feeding and signal cable and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

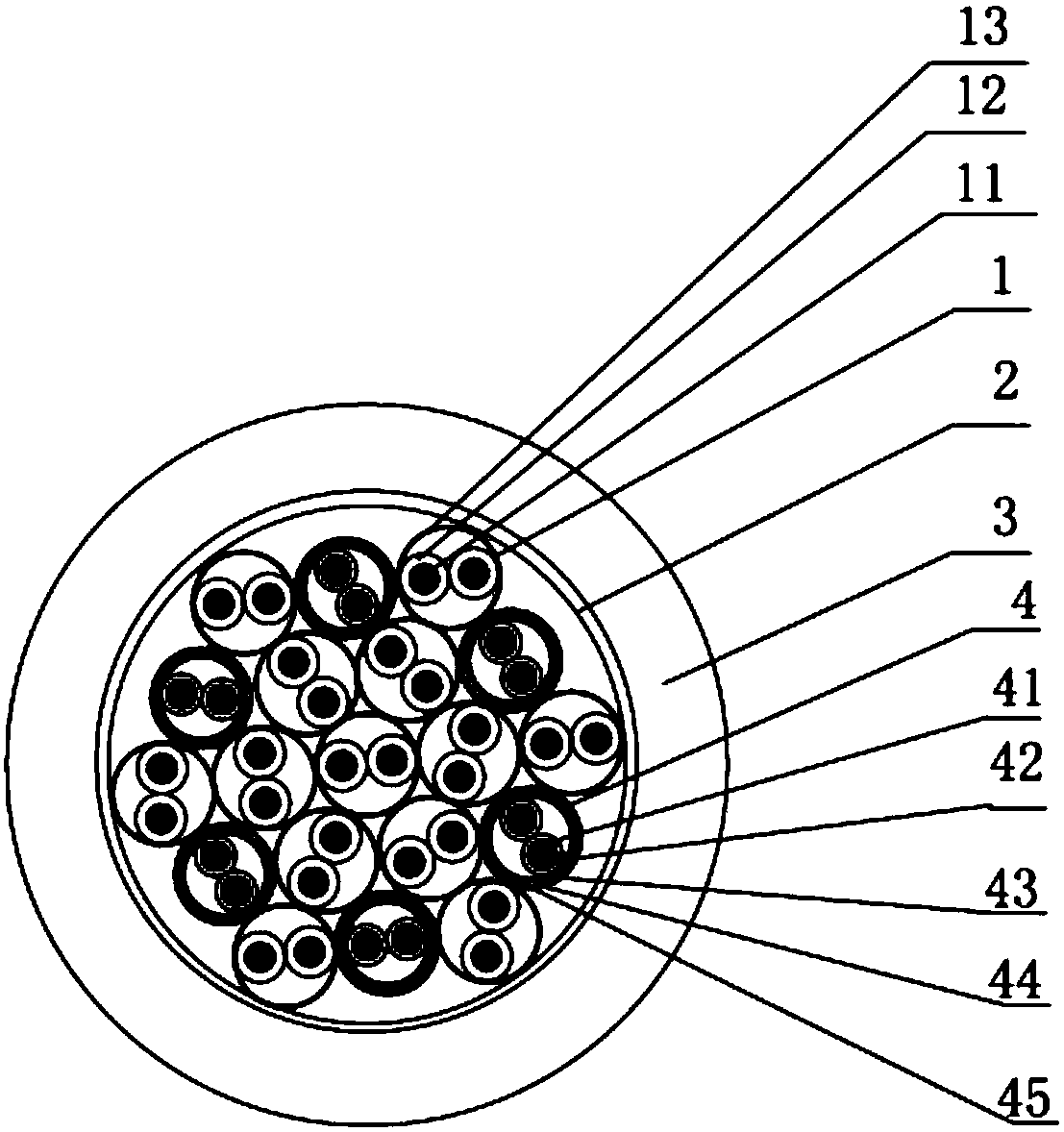

Image

Examples

Embodiment 1

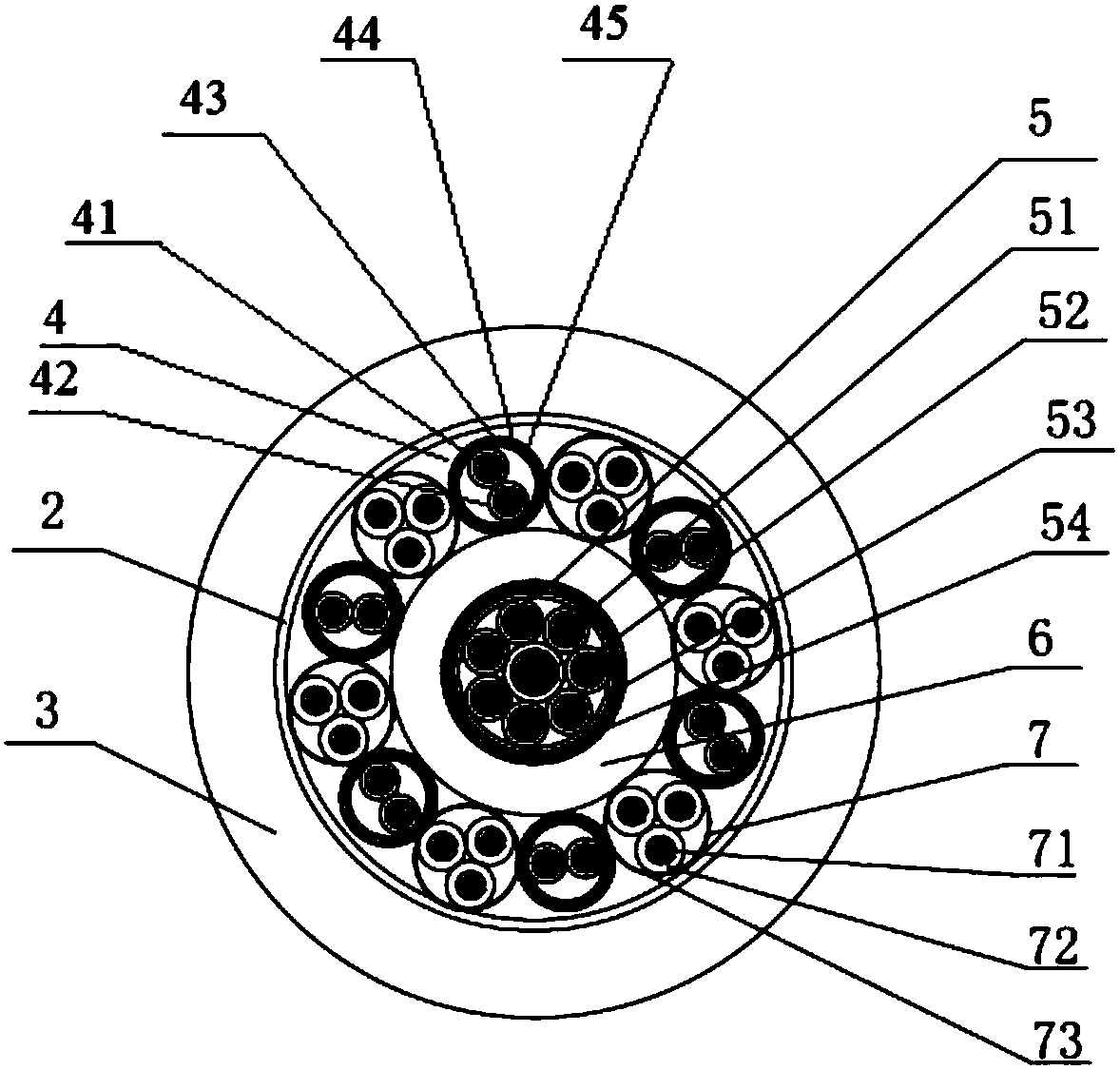

[0064] Such as figure 2 Shown: a flame-retardant and cold-resistant power feed and signal cable, including a central conductor 5, an inner lining 6 wrapping the central conductor 5, 6 sets of 3-core twisted conductors 7 located on the outer periphery of the inner lining 6, and 6 sets of 2-core pairs Twisted metal shielded wires 4 , an isolation layer 2 wrapping the 6 groups of 3-core twisted-pair wires 7 and 6 groups of 2-core twisted-pair metal shielded wires 4 , and an outer sheath 3 outside the isolation layer 2 . The central conductor 5 is twisted with 8 cores 51, and the core 51 is wrapped with an insulating layer 52. The structural combination is 1+7, 7 cores are evenly distributed around the center 1 core, and twisted into a central cable core. The central cable core is wrapped with an isolation layer 53 , and the isolation layer 53 is wrapped with a metal shielding layer 54 . The inner lining layer 6 is wrapped outside the metal shielding layer 54, 6 groups of 2-core...

Embodiment 2

[0088] Similar to Embodiment 1, except that the inner lining layer 6 wraps 8 sets of 3-core twisted-pair conductors 7 and 8 sets of 2-core twisted-pair metal shielded conductors 4 at intervals.

Embodiment 3

[0090] Similar to Embodiment 1, except that the central conductor 5 is stranded with 6 cores 51, the cores 51 are wrapped with an insulating layer 52, the structural combination is 1+5, 5 cores are evenly distributed around the center 1 core, and twisted into a central cable core.

[0091] Description of technical effect of the present invention:

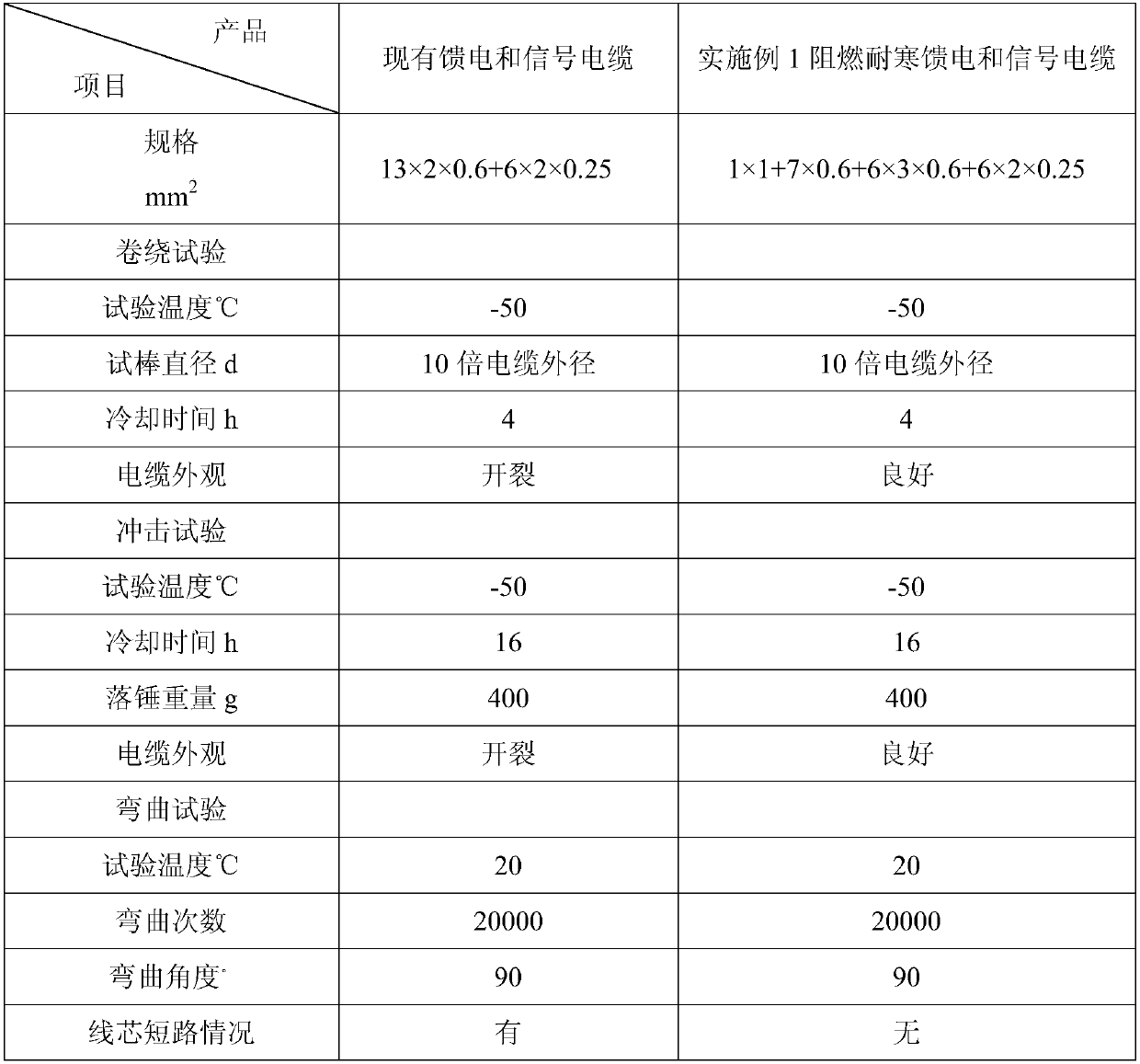

[0092] The existing power feed and signal cables were compared with the flame-retardant and cold-resistant power feed and signal cables produced by the present invention under the same specifications and conditions, and the cable low-temperature pressure test and swing test were compared. The results are shown in Table 1.

[0093] The low-temperature coiling and impact test of the finished cable is based on its operating characteristics, and has been repeatedly verified by the customer after use. It is in accordance with the low-temperature coiling test, low-temperature impact test and bending test of the cold-resistant power feed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com