Anti-torsion reel cable structure

A cable structure and anti-torsion technology, which is applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of unsatisfactory anti-stretch and torsional anti-fatigue performance of reel cables, so as to ensure anti-torsion and prevent insulation layer damage, stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

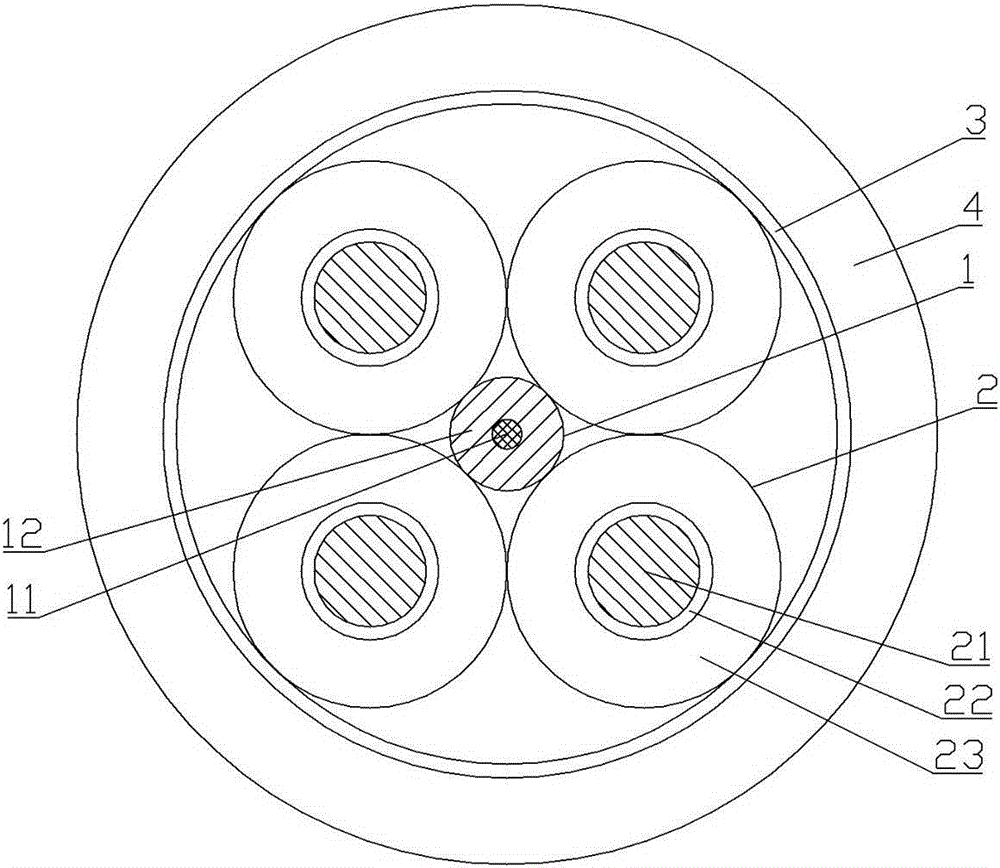

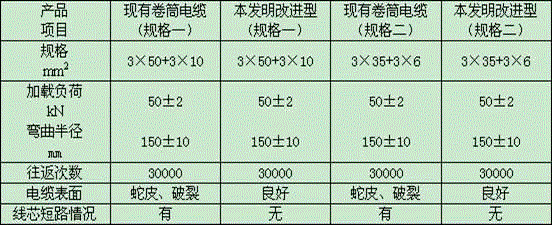

[0025] Such as figure 1 As shown, a torsion-resistant drum cable structure includes a flexible core strip 1, an insulated core 2, an isolation layer 3, and a sheath layer 4. There are four insulated wire cores 2, which are evenly distributed around the flexible core strip 1, twisted into one strand to surround the flexible core strip 1, and the isolation layer 3 uses a gap wrapping method to surround all the insulated core strips 2 to protect The jacket 4 is squeezed out of the isolation layer 3.

[0026] The flexible core strip 1 is composed of a carbon fiber rope 11 and a flexible adhesive layer 12 wrapped around the carbon fiber rope 11. The material of the flexible adhesion layer 72 is silicone rubber.

[0027] The insulated core 2 includes a conductor 21, a temperature insulating layer 22 wrapped outside the conductor 21, and an insulating layer 23 wrapped outside the temperature insulating layer 22. The conductor 21 is formed by twisting a plurality of annealed annealed c...

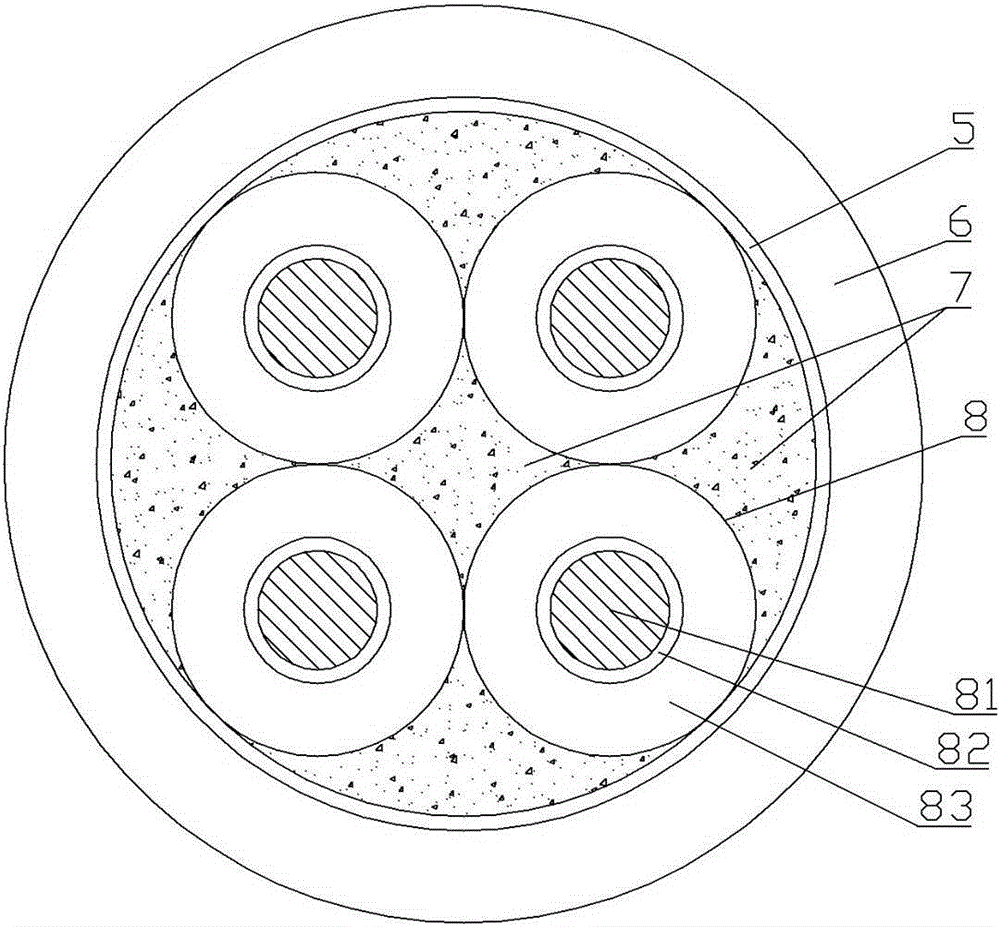

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is that the material formula of the sheath layer 4 is as follows: 100 parts of chlorinated polyethylene rubber, 15 parts of ethylene-butene copolymer, 3 parts of ethylene-vinyl acetate rubber EVA, and magnesium oxide 10 parts, calcium and zinc stabilizer 3 parts, antioxidant 2 parts, stearic acid 0.8 parts, antimony trioxide 9 parts, semi-refined paraffin 2.5 parts, pigment carbon black 18 parts, precipitation method white carbon black 30 parts, active nano 50 parts of kaolin, 18 parts of flame retardant, 19 parts of talc, 21 parts of dioctyl sebacate DOS, 6 parts of auxiliary crosslinking agent, 5 parts of peroxide crosslinking agent.

[0031] The antioxidant includes 1.0 part of antioxidant RD and 1.0 part of antioxidant MB.

[0032] The beneficial effects of this formula are as follows: During the refining process, chlorinated polyethylene rubber, ethylene-butene copolymer and ethylene-vinyl acetate rubber EVA are ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com