Manufacturing method for improving packaging and positioning precision of two-piece type frame

A positioning accuracy and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of positioning accuracy and positioning error accumulation, inability to move relatively, expansion of positioning deviation, etc., to avoid positioning The effect of large deviation, improving positioning accuracy and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

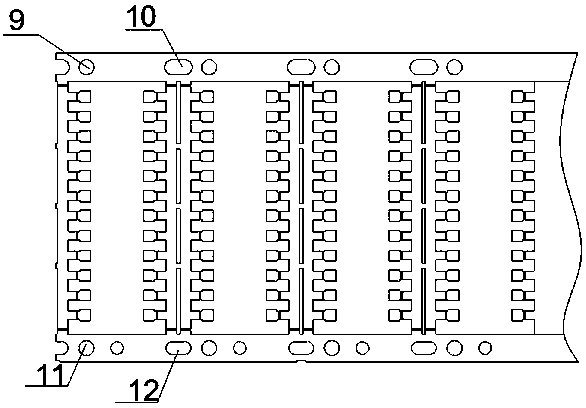

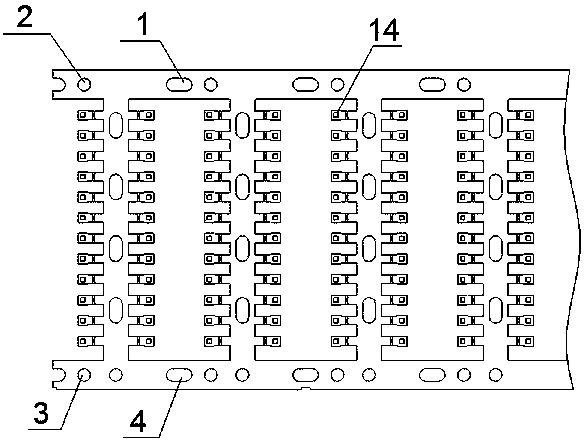

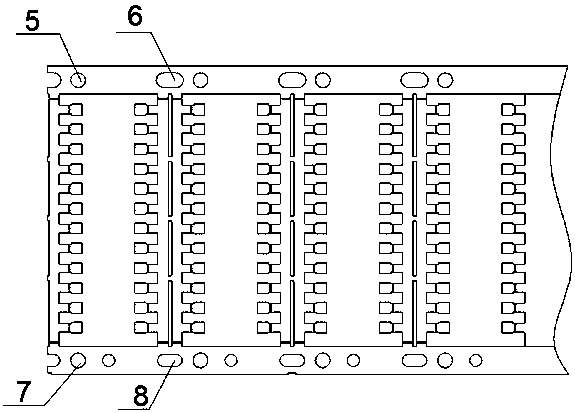

[0024] Such as Figure 1-5 As shown, a manufacturing method for improving the positioning accuracy of a two-piece frame package includes the following steps:

[0025] a. Position the lower frame 15 on the graphite jig;

[0026] b. Apply an appropriate amount of solder paste on the slide table of the lower frame 15;

[0027] c. Mount the chip on the carrier table of the lower frame 15;

[0028] d. Apply an appropriate amount of solder paste on the carrier table of the upper frame 14;

[0029] e. Cover the upper frame 14 on the lower frame 15, and use the positioning pin 13 to pass through the welding step positioning round hole group 11 and the welding step positioning elongated hole group 12 to align and position;

[0030] f. Perform high-temperature welding on the combined upper and lower frames;

[0031] g, use the positioning needle 13 to pass through the encapsulation step to locate the round hole group 9, and the encapsulation step to locate the long hole group 10 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com