Array substrate and preparation method thereof

An array substrate and substrate technology, applied in the field of array substrate and its preparation, can solve the problems affecting the characteristics of TFT, the black screen of the display panel, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

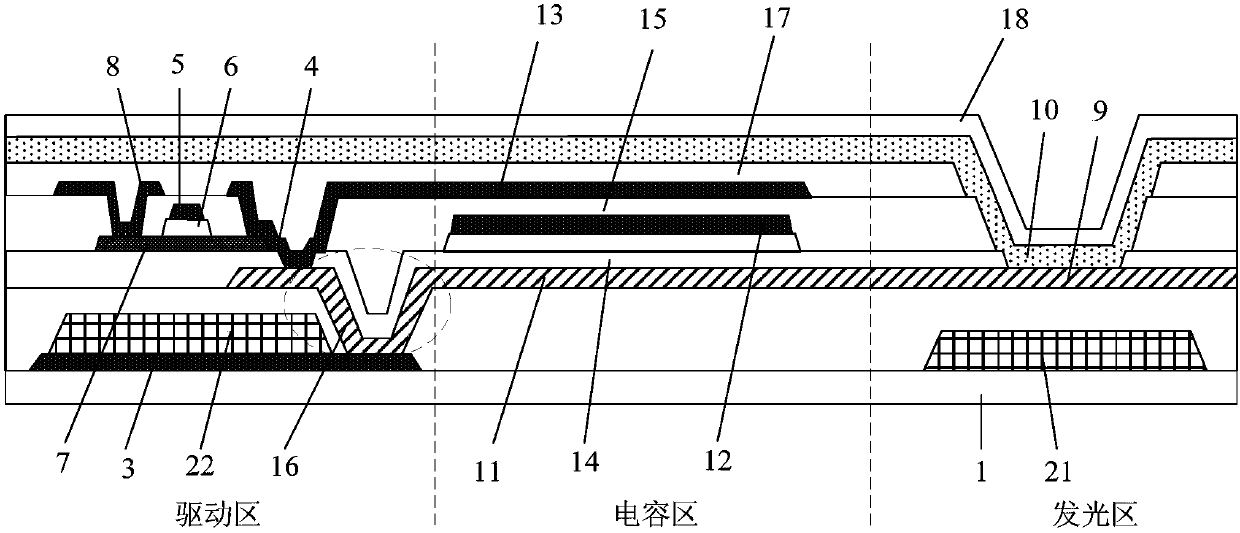

[0027] Such as figure 1 As shown, this embodiment provides an organic light emitting diode (OLED) array substrate, which includes a base 1, the base 1 is divided into a plurality of sub-pixels of different colors, each sub-pixel includes a driving region, a capacitor region and a light-emitting region, each At least one thin-film transistor (TFT) is arranged in the driving region; an organic light-emitting diode is arranged in the light-emitting region, and a first color filter structure 21 corresponding to the color of the sub-pixel where the light-emitting region is located is arranged below the organic light-emitting diode. In particular, the thin-film transistor A second color filter structure 22 is arranged below, and the second color filter structure 22 is arranged on the same layer as the first color filter structure 21 of at least one color.

[0028] Among them, up and down refer to the direction, specifically, such as figure 1 As shown, all the structures of the arra...

Embodiment 2

[0050] This embodiment provides a method for preparing an array substrate, which is used to prepare the array substrate provided in Embodiment 1. The preparation method includes:

[0051] Step 1. Using a patterning process on the base corresponding to the thin film transistor and the organic light-emitting diode in the sub-pixel of one color, respectively form the graphics of the second color filter structure and the first color filter structure.

[0052] Step 2, forming organic light emitting diodes and thin film transistors on the substrate after the above steps.

[0053] In the array substrate prepared by the preparation method provided in this embodiment, a first color filter structure is provided below the organic light emitting diode, and a second color filter structure is provided below the thin film transistor. The position is elevated, shortening the distance between the thin film transistor and the organic light emitting diode in the longitudinal direction, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com