Array substrate and preparation method thereof

An array substrate and substrate technology, applied in the field of array substrate and its preparation, can solve the problems of high production cost, long cycle, cumbersome preparation method steps, etc., and achieve the effects of improving production capacity, reducing production cost and reducing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

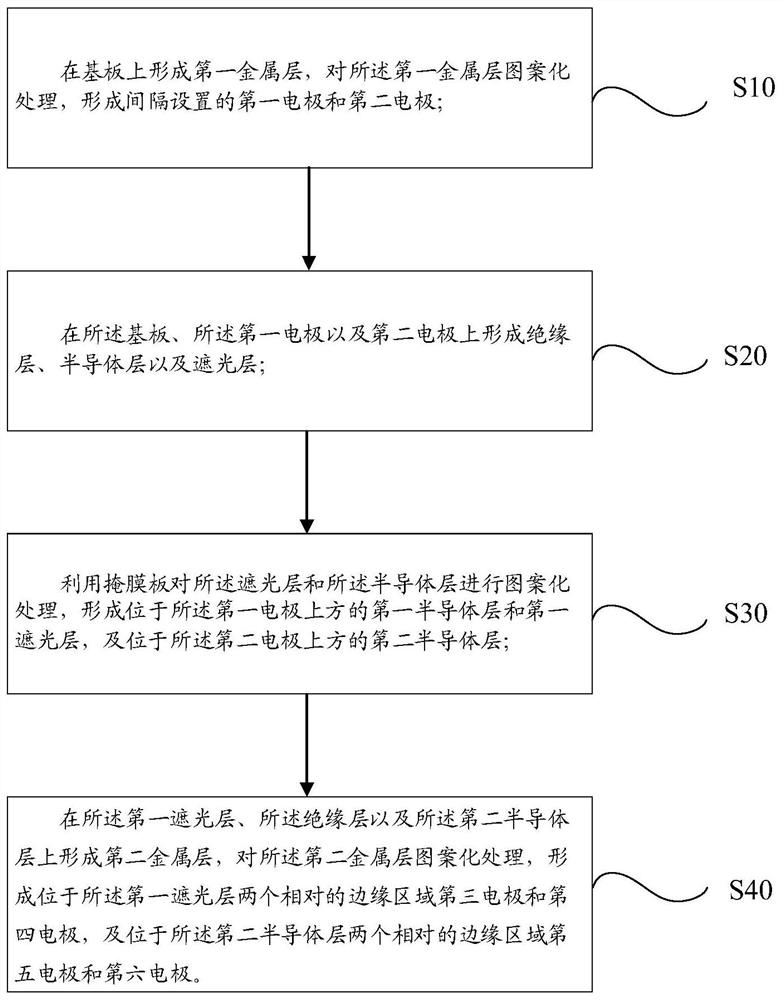

[0051] see figure 1 , a schematic diagram of the process flow of the array substrate provided in the embodiment of the present application.

[0052] In this embodiment, the preparation method of the array substrate includes:

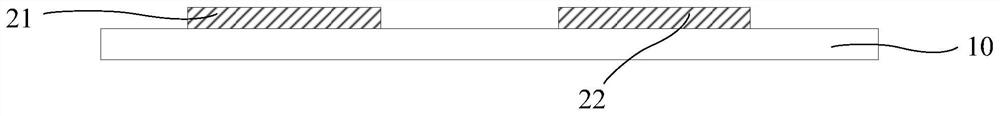

[0053] Step S10: forming a first metal layer on the substrate 10, and patterning the first metal layer to form first electrodes 21 and second electrodes 22 arranged at intervals, such as Figure 2A shown.

[0054]In this embodiment, the step S10 includes the following steps:

[0055] Step S11: providing a substrate 10, the substrate 10 includes but not limited to a glass substrate and a flexible substrate.

[0056] Further, in this embodiment, the substrate 10 is a flexible and transparent PI substrate, mainly polyimide, and the PI material can effectively improve light transmittance.

[0057] Step S12: Depositing a first metal layer on the substrate 10, the material of the first metal layer includes but not limited to metals such as aluminum, molybd...

Embodiment 2

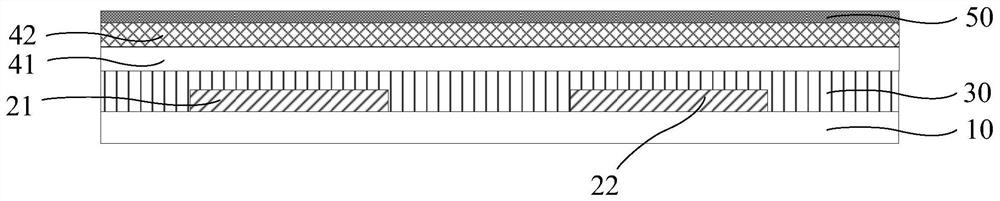

[0094] see image 3 , a schematic structural diagram of the array substrate provided in the embodiment of the present application.

[0095] In this embodiment, the array substrate includes a substrate 10; a switch thin film transistor 100, the switch thin film transistor 100 is arranged in an array on the substrate 10, and the switch thin film transistor 100 includes a stacked first electrode 21 and a The first semiconductor layer 401; the photosensitive thin film transistor 200, the photosensitive thin film transistor 200 is arranged on the substrate 10, the photosensitive thin film transistor 200 includes the second electrode 22 and the second semiconductor layer 402 arranged in a stack; wherein, the photosensitive thin film transistor 200 The switching thin film transistor 100 is spaced apart from the photosensitive thin film transistor 200 , and the switching thin film transistor 100 further includes a light shielding layer 50 located above the first semiconductor layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com