Food conveyance pipeline sterilizing device and method

A food conveying and disinfection device technology, applied in disinfection, chemistry, etc., can solve the problems of excessive disinfectant, poor safety performance, inconvenience, etc., and achieve the effect of wide application range, high ozone utilization rate and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

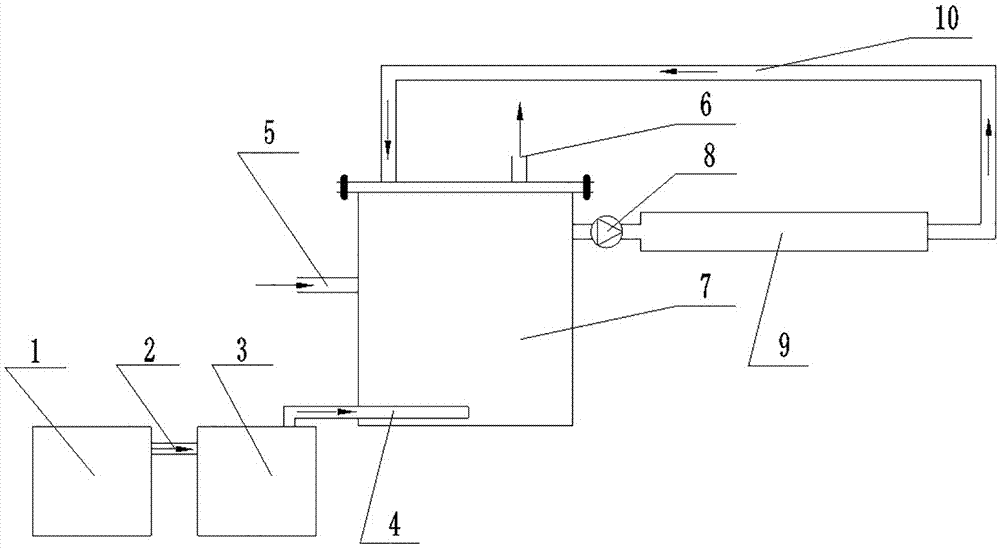

[0025] Such as figure 1 As shown, the main device of the present invention comprises an ozone generator 1, a metal pipe 2, a microbubble generator 3, a diffusion pipe 4, a water inlet pipe 5, an emptying pipe 6, a dissolving device 7, a water pump 8, a food delivery pipeline 9, an ozone Water return pipe 10. The ozone generated by the ozone generator 1 is transported to the micro-bubble generator 3 through the metal pipe 2, the micro-bubbles containing ozone in the micro-bubble generator 3 are transported to the dissolving device 7 through the diffusion tube 4, and the water in the water inlet pipe 5 is transported to the dissolving device 7. The emptying pipe 6 empties the gas in the dissolving device 7; the high-concentration ozone-containing microbubbles formed in the dissolving device 7 are transported to the food delivery pipeline 9 by the water pump 8, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com