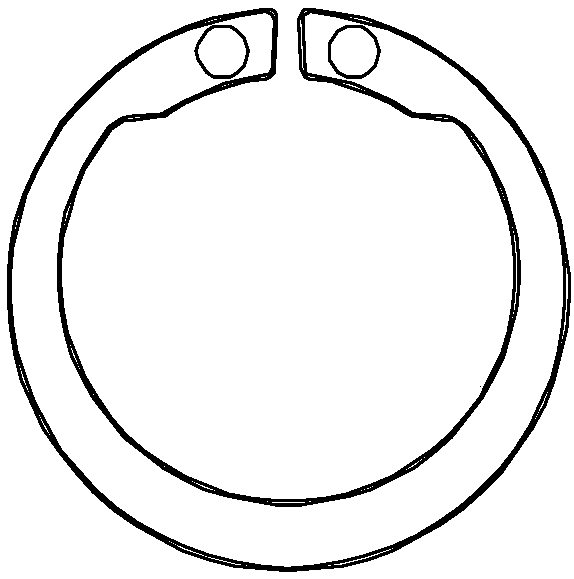

Narrow-mouth baffle ring continuous mould stamping equipment

A technology for stamping equipment and retaining rings, which is applied in the field of continuous die stamping equipment for narrow-mouth retaining rings, can solve problems such as narrow waste connection parts, blocked product discharge, and narrow mouths, so as to achieve reasonable structural design, improve processing efficiency, and prevent The effect of secondary damage to the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

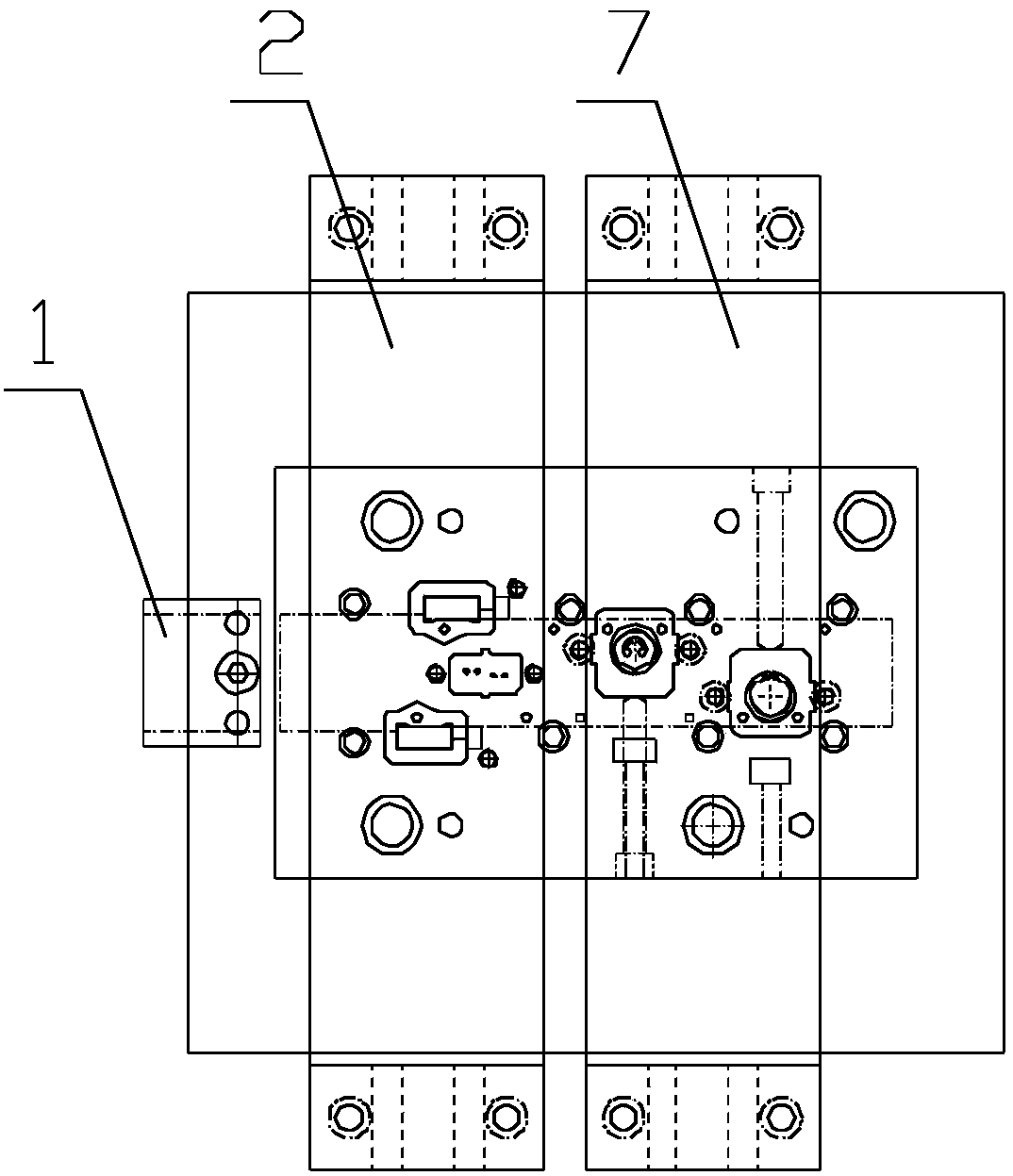

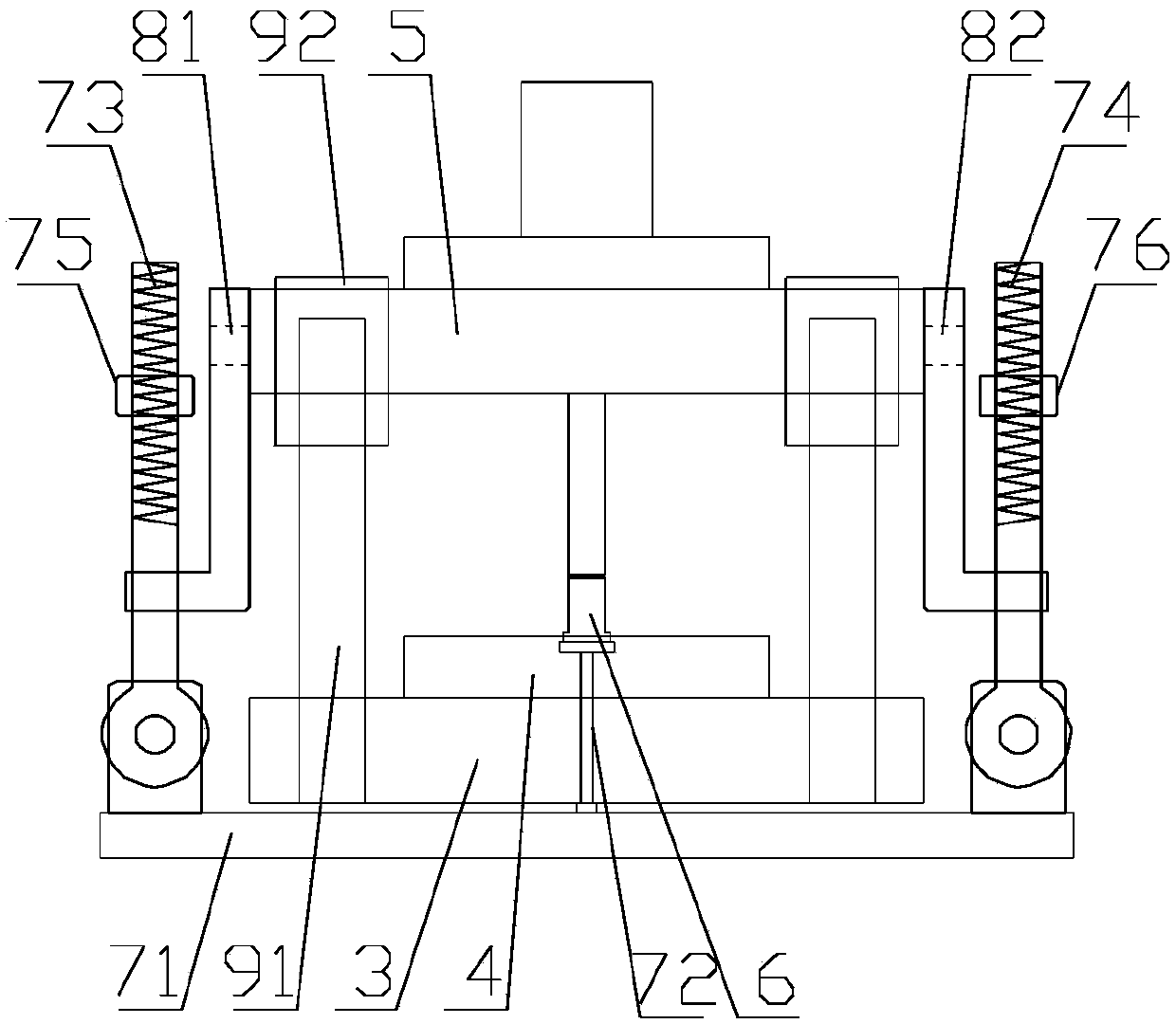

[0019] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a continuous die stamping equipment for a narrow retaining ring proposed by the present invention, figure 2 It is a structural schematic diagram of a continuous die stamping equipment for a narrow retaining ring proposed by the present invention, image 3 It is a structural schematic diagram of the second stamping mechanism of a continuous die stamping equipment for a narrow retaining ring proposed by the present invention.

[0020] refer to figure 2 and 3 , a continuous die punching equipment for a narrow retaining ring proposed by the present invention, comprising: a feeding device 1, a second punching mechanism 7;

[0021] The feeding device 1 is located on the side of the feed port of the second stamping mechanism, and is used for continuously feeding materials into the second stamping mechanism 7;

[0022] The second stamping mechanism 7 includes a lower template 3, a die 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com