Stirring device for construction sites

A mixing device and building construction technology, which is applied to cement mixing devices, mixing plants, clay preparation devices, etc., can solve the problems of large difference in specific gravity, change, and large dosage, and achieve the effects of low cost, increased production, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

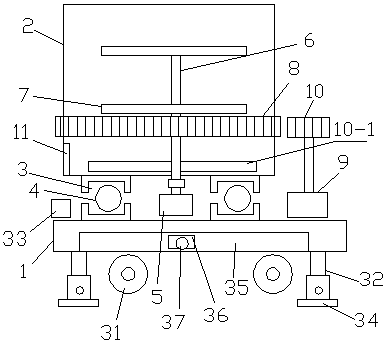

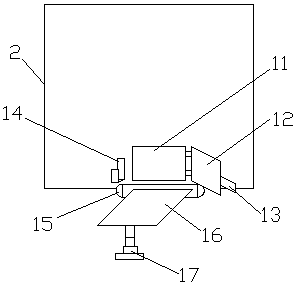

[0010] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] A stirring device for building construction, comprising a circular base 1, the base 1 is provided with a mixing tank 2, the lower surface of the mixing tank 2 is provided with an annular rolling groove 3 at a position corresponding to the upper surface of the base 1, Balls 4 are provided in the rolling groove 3, and a No. 1 motor 5 is provided in the middle of the base 1. The output shaft of the No. 1 motor 5 is connected to the vertical shaft 6 through a coupling, and the vertical shaft 6 extends to the mixing tank. 2 is connected with the stirring blade 7, the circumference of the mixing bucket 2 is provided with a rack 8, the side of the upper surface of the base 1 is provided with a No. 2 motor 9, and the output shaft of the No. 2 motor 9 is provided with a gear The gear 10 matched with the bar 8, the barrel wall of the mixing buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com