Gas-assisted injection molding device facilitating gas injection

A gas-assisted injection molding and gas injection technology, which is applied in the field of injection molding devices, can solve problems such as insufficient control of compressed gas and leakage of compressed gas, and achieve the effects of easy removal, avoidance of leakage, and convenient closing and opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

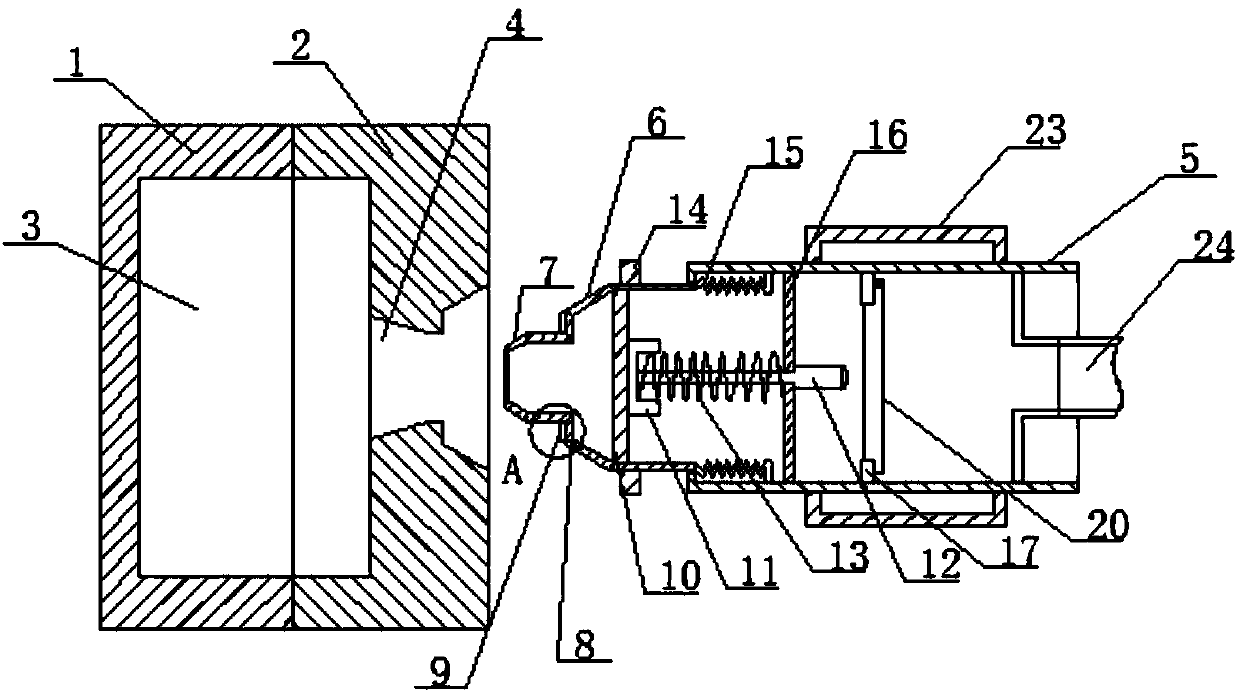

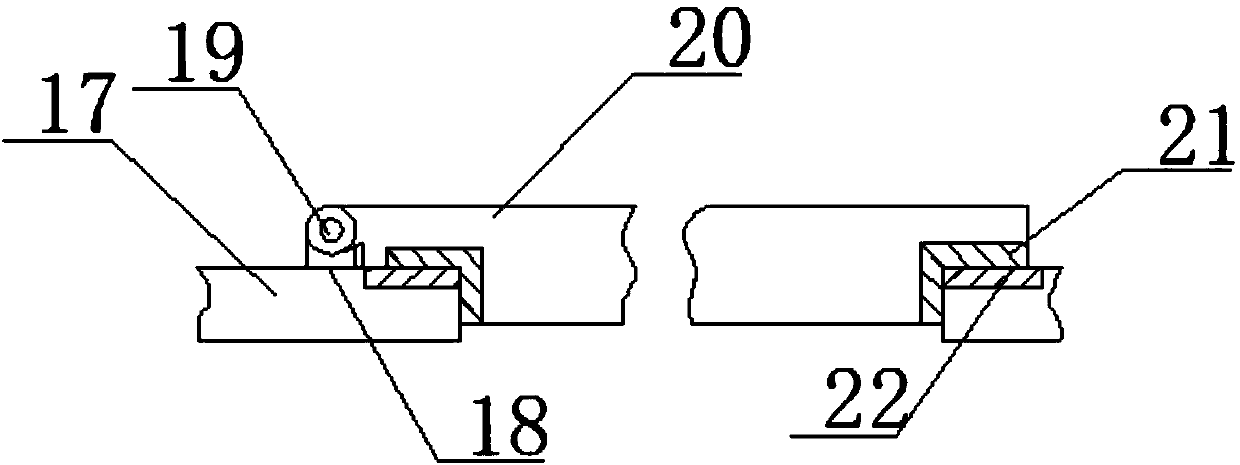

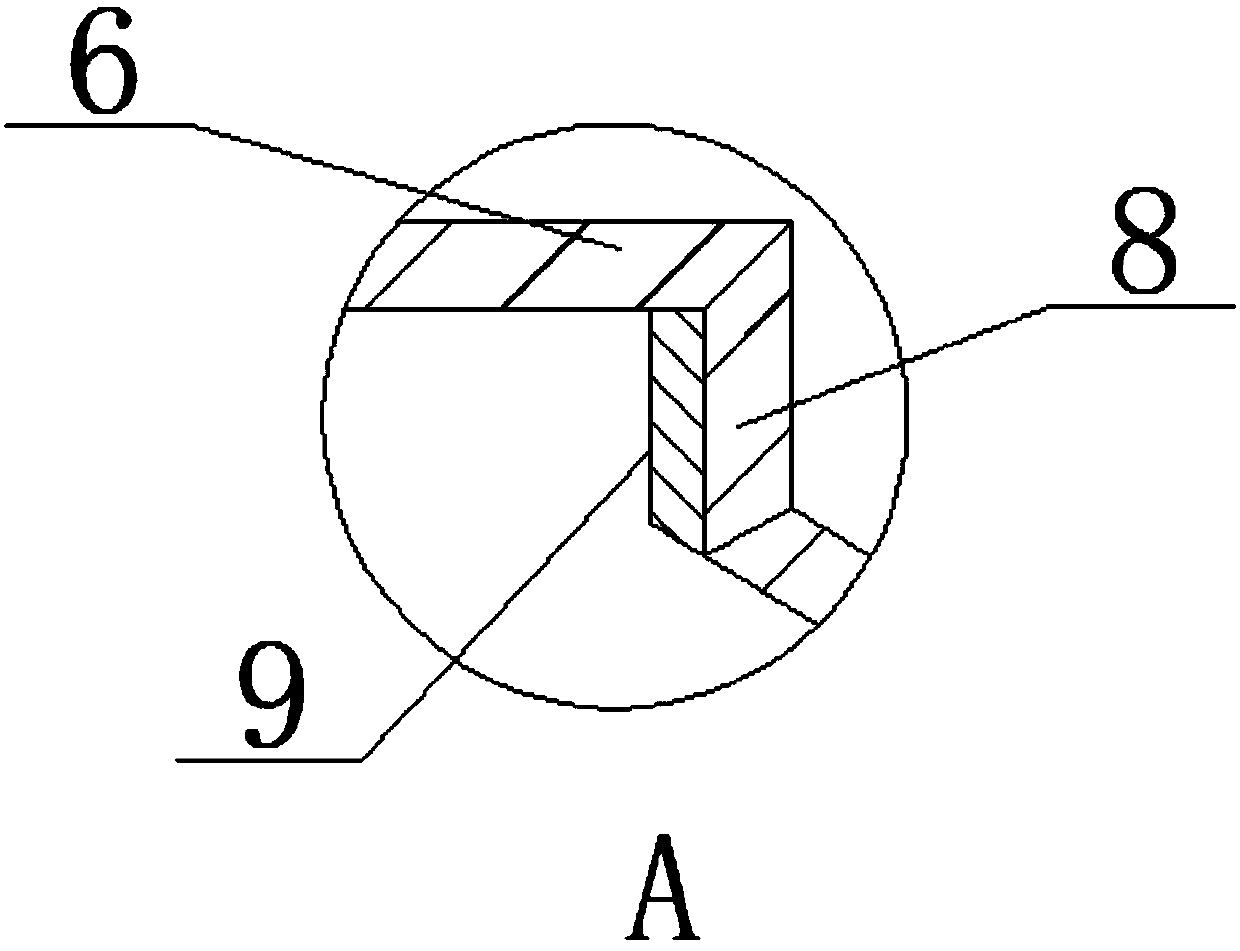

[0023] see Figure 1-Figure 3 As shown, a gas-assisted injection molding device that facilitates gas injection includes a fixed mold 1, a gas barrel 5 and a moving muzzle 6. The fixed mold 1 and the moving mold 2 are connected in contact, and the fixed mold 1 and the moving mold 2 can be easily separated. , to facilitate the removal of the plastic parts, the fixed mold 1 and the movable mold 2 are provided with a cavity 3, the cavity 3 matches the molded plastic part, and is used to shape the material, and the side of the movable mold 2 is provided with an injection port 4, While being used as the injection port of the material, the gun body can be supported. The gas gun barrel 5 is connected with the moving muzzle 6 through the elastic member 15, which can ensure the sealing performance while being connected to each other. The top of the moving muzzle 6 is provided with a The air port 7 and one side of the air outlet 7 are connected to the extruded end face 8, and the extrude...

Embodiment 2

[0025] In addition, refer to Figure 1-Figure 3 , based on the above embodiment, the fixed mold 1 is matched with the movable mold 2, and the fixed mold 1 and the movable mold 2 are connected in contact, and a matching cavity 3 is set in the fixed mold 1 and the movable mold 2, so that the device can inject the corresponding shape At the same time, it is convenient to take out the product. The injection port 4 is set obliquely. The shape of the injection port 4 matches the shape of the moving muzzle 6, so that the injection port 4 can be in close contact with the moving muzzle 6, which is easy to seal. The moving muzzle 6 can be horizontally direction to move a certain distance, the gas gun barrel 5 and the moving muzzle 6 are movably connected, so that the gun body can automatically open the compressed gas, which is convenient for the device to pass into the compressed gas. 8 is provided with a matching rubber ring 9, and the width of the extrusion end face 8 is set to match ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com