Laminating-drying integrated tank for paper mounting machine

A paper laminating machine and an integrated technology, applied in paper pasting, decorative arts, etc., can solve the problems of moldy and deformed paper, and achieve the effects of not being moldy, promoting circulation, and speeding up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

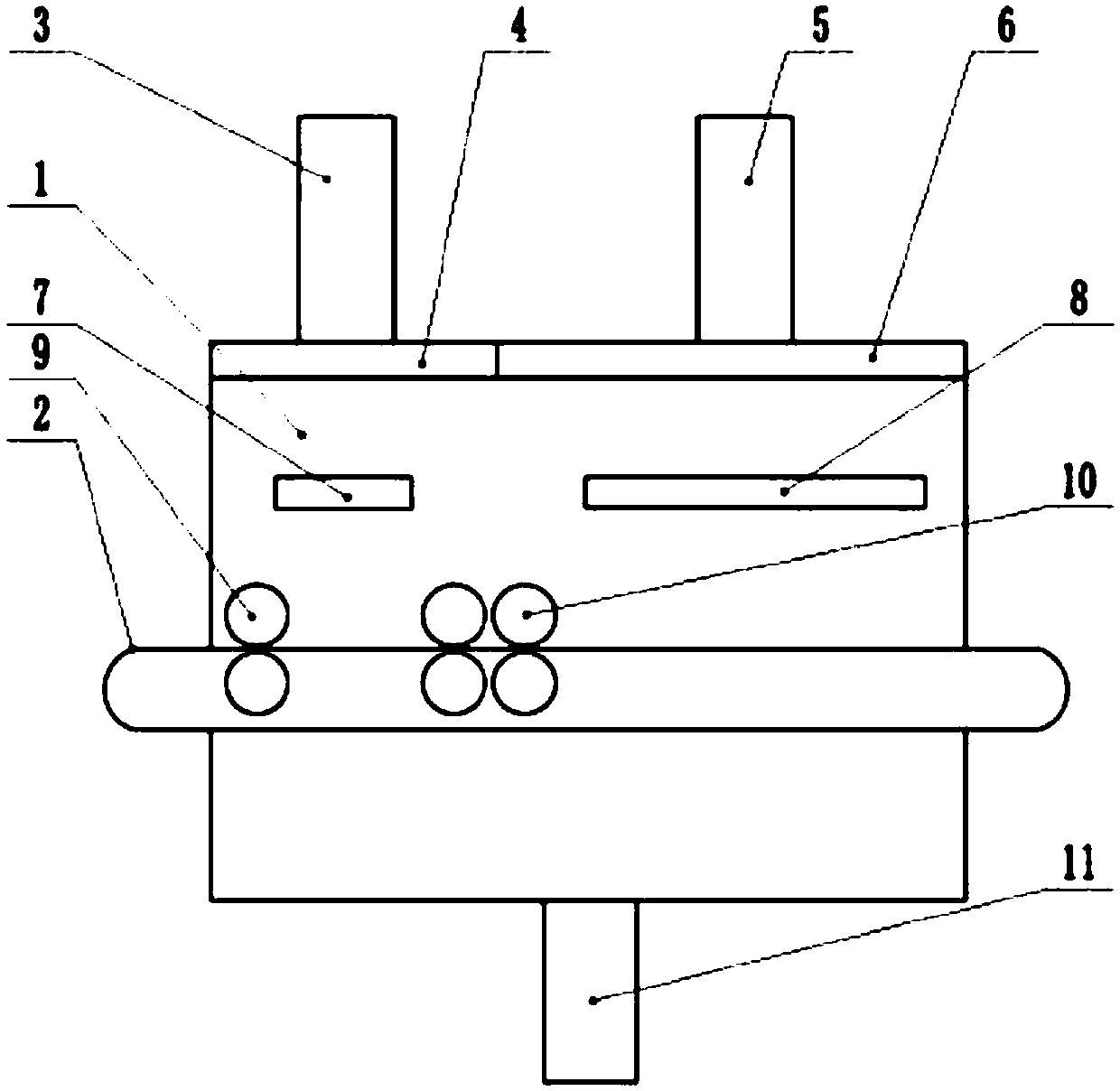

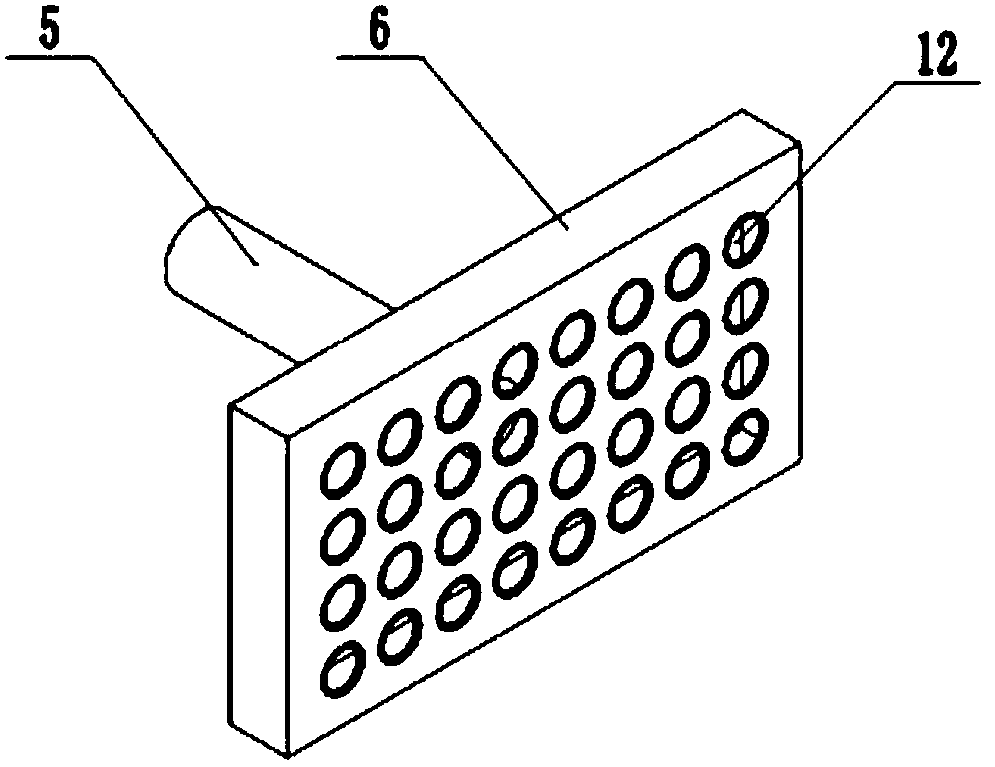

[0014] like figure 1 , 2 As shown, a pressing and drying integrated box for a laminating machine is characterized in that it includes a box body 1, a conveyor belt 2, the first group of rollers 9 and the second group of rollers 10, and the conveyor belt 2 is located in the box Inside the body 1, both ends of the conveyor belt 2 protrude from the box body 1, the conveyor belt 2 is parallel to the lower surface of the box body 1, the first group of rollers 9 is composed of upper and lower rollers, and the second group of rollers Shaft 10 consists of two upper and lower rollers. The upper belt of the conveyor belt 2 passes through the No. 1 roller 9 and the No. 2 roller 10 successively. The No. 1 roller 9 and the No. 2 roller 10 The axis is parallel to the lower surface of the box 1, the upper end of the box 1 is provided with a No. 1 exhaust plate 4 and a No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com