Front and rear dual-drive all-electric permanent-magnet shaftless vector propulsion structure for high-speed submarine

A technology of vector propulsion and vector propulsion, which is applied in the field of front and rear double-drive all-electric permanent magnet shaftless vector propulsion structures for high-speed submarines. Achieve the effects of reducing turbulence, increasing maneuverability and flexibility, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

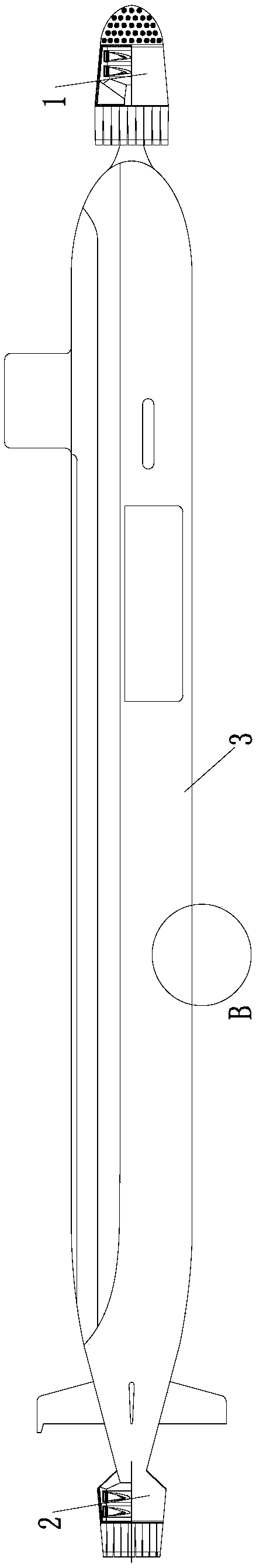

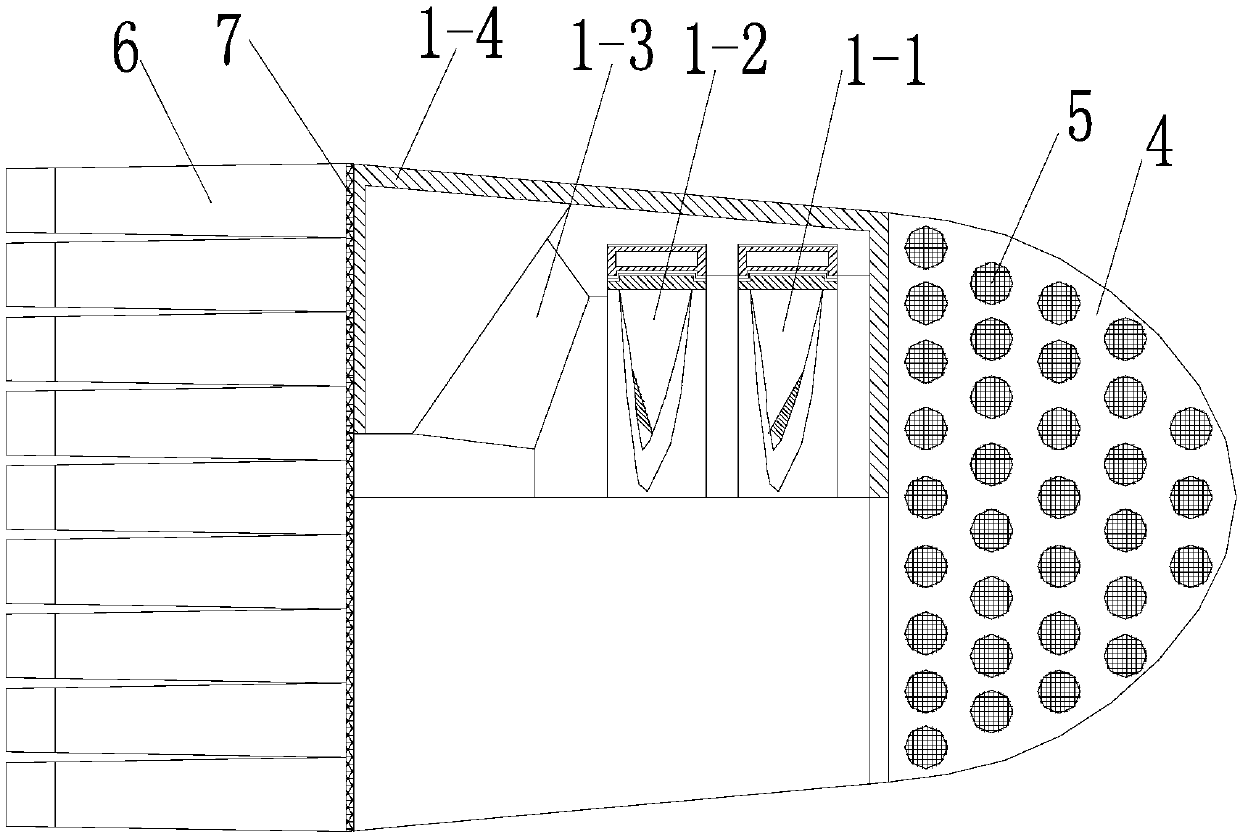

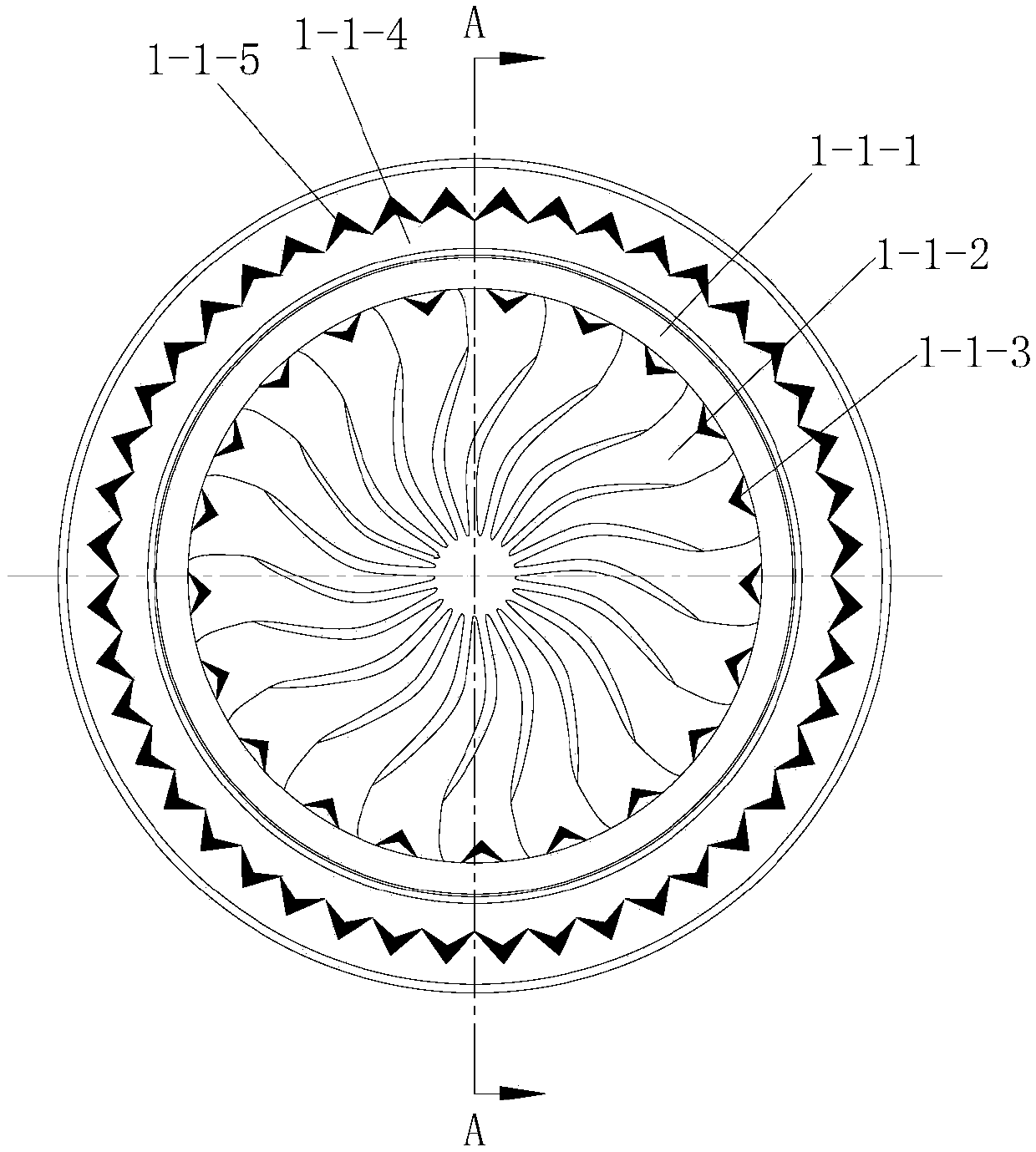

[0046] Such as Figure 1 to Figure 7 As shown, the present invention includes a front all-electric permanent magnet shaftless vector propeller 1 arranged at the head of the submarine and connected to the front end of the submarine cavitation maintenance housing 3 and arranged at the tail of the submarine and connected to the rear end of the submarine cavitation maintenance housing 3 The rear all-electric permanent magnet shaftless vector thruster 2, the front end of the front full electric permanent magnet shaftless vector thruster 1 is equipped with a front anti-marine life shell 4, and the front full electric permanent magnet shaftless vector thruster 1 The rear end is equipped with a front three-element vector rectifying nozzle, the front end of the rear all-electric permanent magnet shaftless vector propeller 2 is installed with a rear anti-marine life shell 10, and the rear all-electric permanent magnet shaftless vector propeller 2 The rear end is equipped with a rear thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com