Unmanned helicopter complex-shaped composite-material integral oil tank structure

A technology of unmanned helicopters and composite materials, which is applied in the field of unmanned helicopter complex-shaped composite material integral fuel tank structure, achieving the effect of high space utilization, reduced space utilization, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

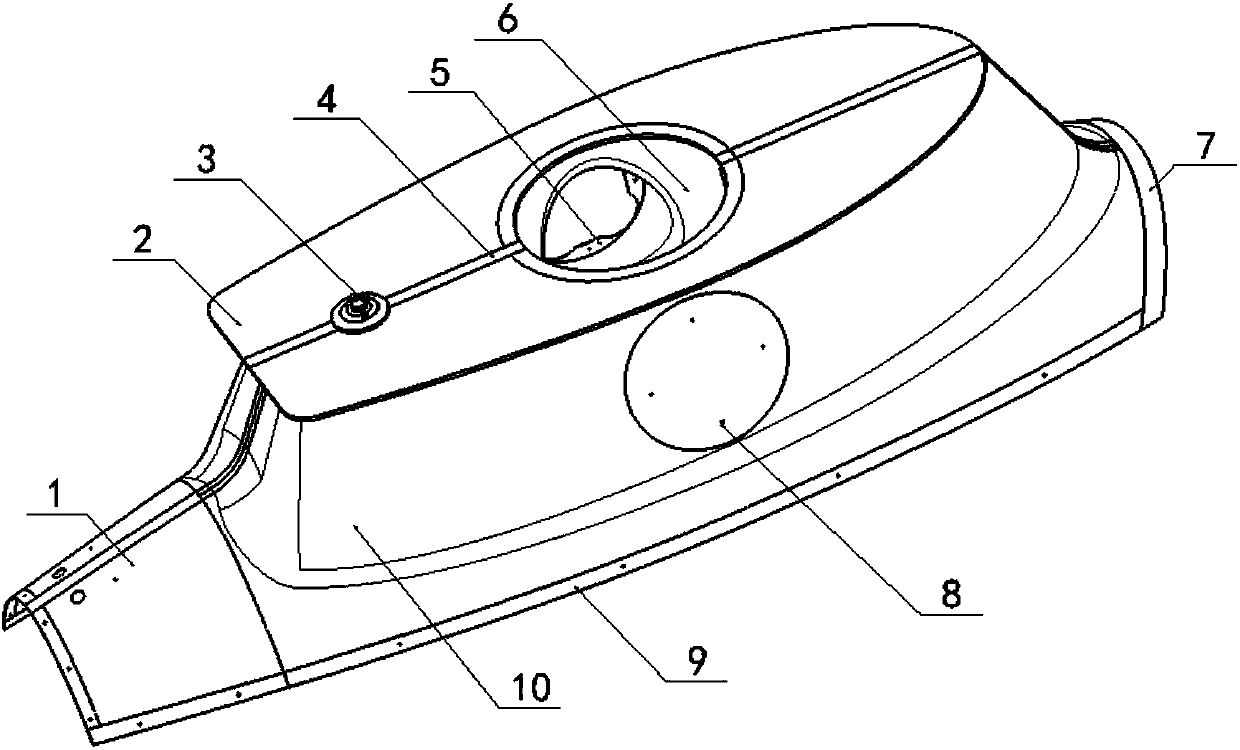

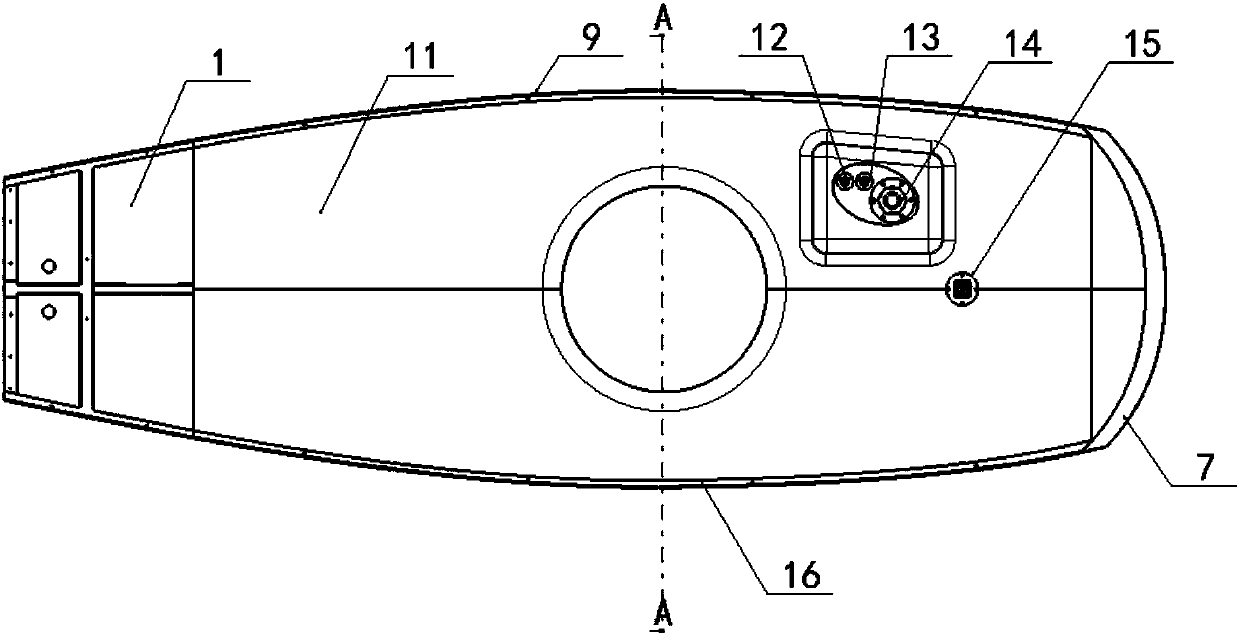

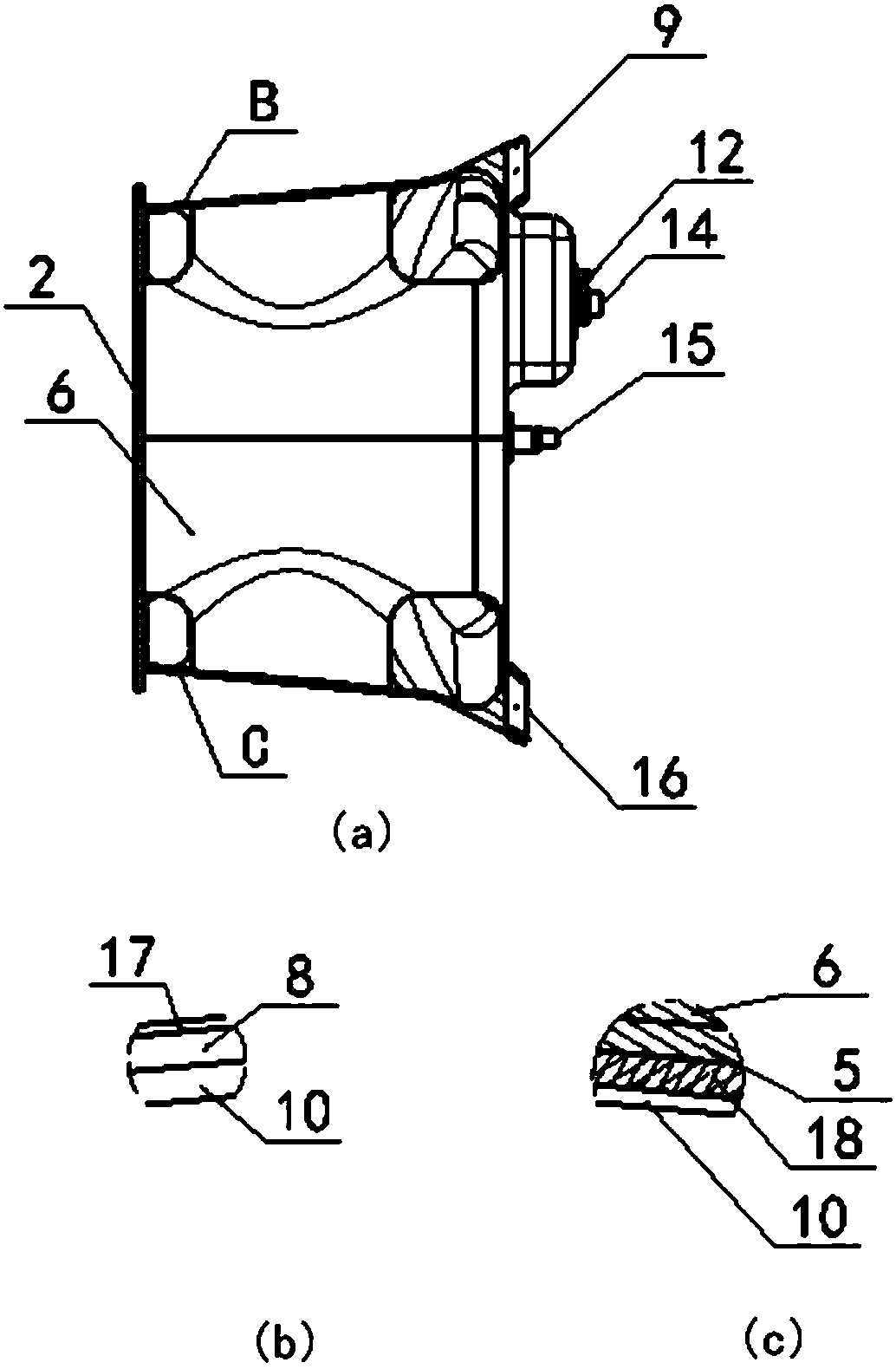

[0027] Such as figure 1 , 2 , 3, an unmanned helicopter of the present invention has a complex shape composite material integral fuel tank structure, including a fuel tank cover 2, a fuel tank body, a fuel filler 3, an oil outlet 14, an oil supply port 12, an oil return port 13, and an oil level measurement Device 15, copper mesh 4, left metal profile 5, right metal profile 18, left flap 17, right flap 8 and other parts. Although the fuel tank body is integrally formed, it is too complicated. It is divided into seven parts: the middle section 6, the side 10, the bottom 11, the front skirt 7, the rear skirt 1, the left skirt 16, and the right skirt 9. Analysis and explanation. The fuel tank cover is connected with the fuel tank body, fuel filler and copper mesh by glue connection; the fuel tank body is connected with the oil outlet, fuel supply port, oil return port and oil level gauge by blind hole flange bolts, and the copper mesh The net and the left and right metal profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com