Super high strength magnet yoke steel and manufacturing method thereof

A technology of ultra-high strength and manufacturing method, which is applied in the field of ultra-high-strength yoke steel and its manufacturing, which can solve the problem of low strength, lack of magnetic properties of yoke steel, and failure to meet high-strength and good magnetic properties of high-head hydropower generators Requirements and other issues to achieve high strength, good magnetic induction performance, and improve the effect of tissue strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

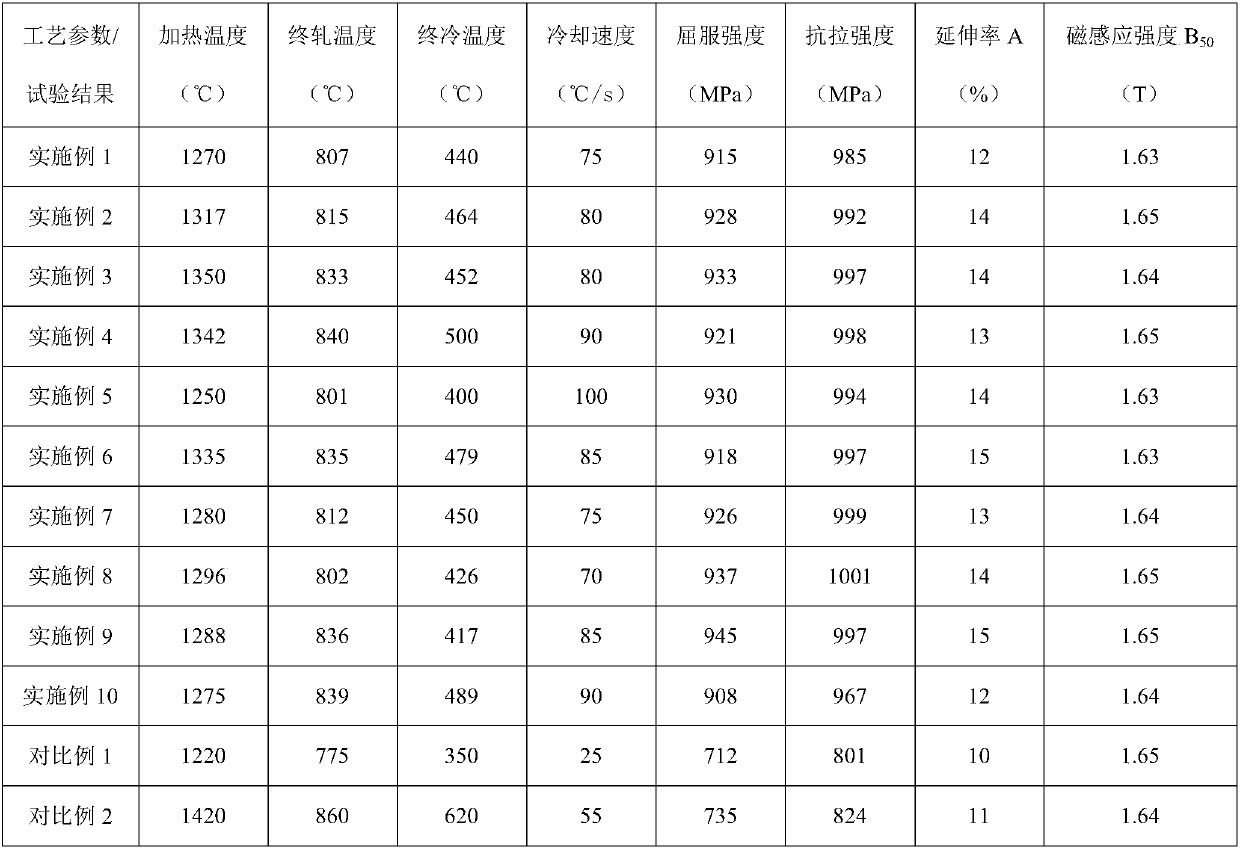

Embodiment 1-10

[0021] The chemical composition (wt%) of the ultra-high-strength yoke steel described in Examples 1-10 is specifically shown in Table 1.

[0022] Table 1

[0023] Element

C

mn

Si

P

S

als

Ti

Nb

Mo

B

N

Example 1

0.10

1.96

0.02

0.015

0.006

0.05

0.21

0.7

0.55

0.003

0.006

Example 2

0.14

1.90

0.06

0.013

0.004

0.07

0.28

0.05

0.35

0.001

0.005

Example 3

0.12

1.95

0.03

0.012

0.006

0.10

0.24

0.07

0.40

0.002

0.006

Example 4

0.15

1.86

0.15

0.011

0.008

0.02

0.28

0.07

0.45

0.002

0.005

Example 5

0.11

1.98

0.10

0.012

0.005

0.03

0.23

0.06

0.49

0.003

0.008

Example 6

0.15

1.94

0.08

0.010

0.010

0.08

0.30

0.06

0.37

0.001

0.005

Example 7

0.11

1.86

0.03

0.012

0.006

0.05

0.22

0.05

0.40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com